Environment-friendly wear-resistant tensile power cable

A power cable, an environment-friendly technology, applied in the field of environment-friendly wear-resistant and tensile power cables, can solve the problems of disconnection at the cable interface, failure of the cable to meet the flame retardant performance, waterproof performance, and influence on the normal operation of the power cable, etc., to achieve enhanced Tensile and wear resistance, enhanced flame retardant effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

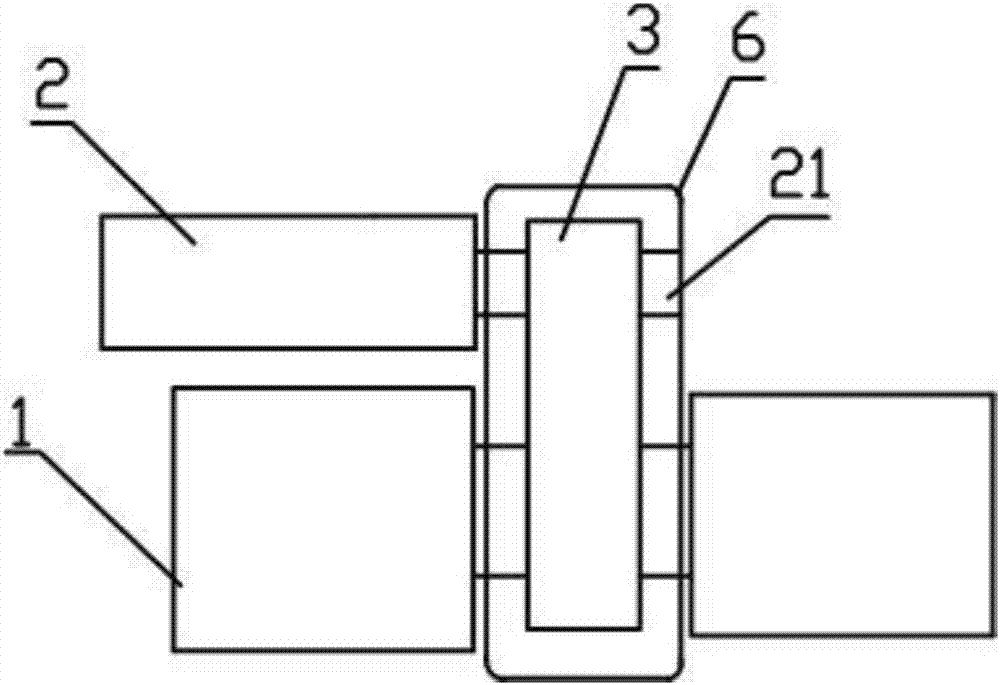

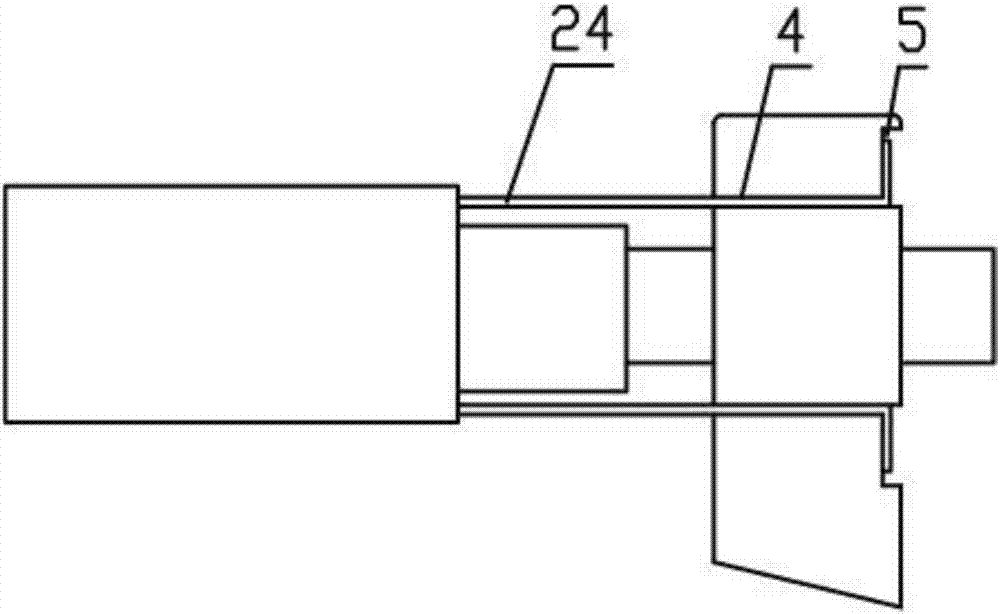

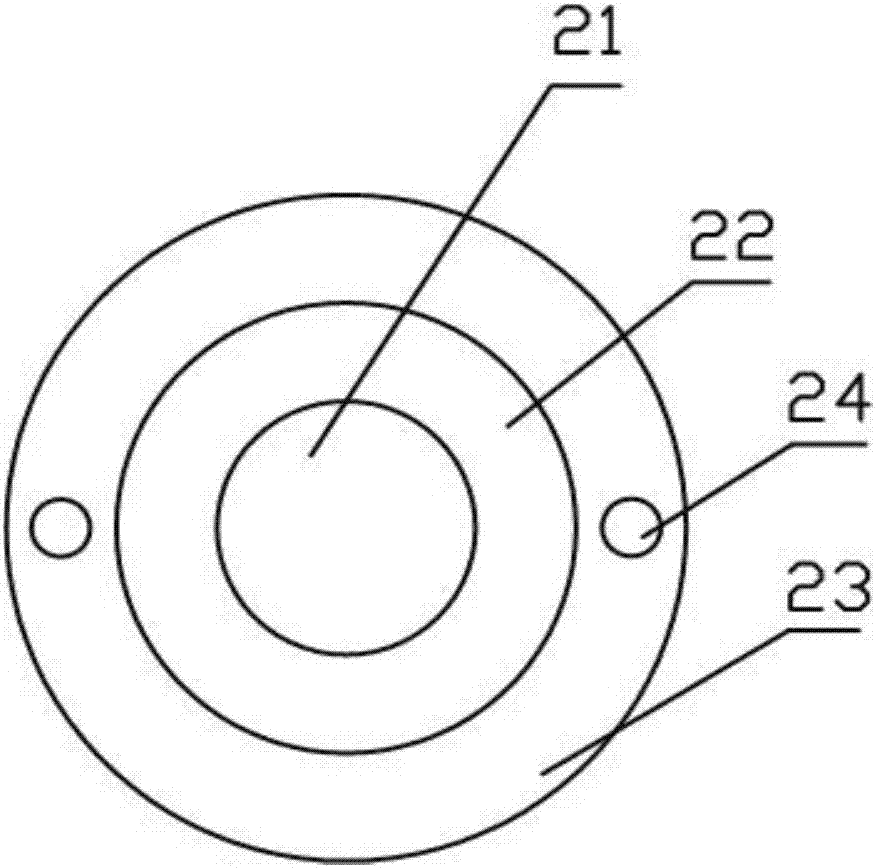

[0025] Such as Figure 1~3 As shown, the present invention provides an environment-friendly wear-resistant and tensile power cable, including a master cable 1 and a slave cable 2, the master cable 1 and the slave cable 2 are arranged in parallel, and the master cable 1 and the slave cable 2 are connected through a connecting joint 3, The connecting joint 3 can adopt a C-shaped clamp, and the cable 2 includes a conductor 21, an insulating layer 22 and a sheath 23, and the sheath 23 is embedded with two steel wires 24; The steel wire 24 is matched with the through hole 4, and the steel wire 24 at the access end of the cable 2 is inserted into the through hole 4; The limiting groove 5, the steel wire 24 stretches out of the through hole 4 sections and bends into the limiting groove 5; the connecting joint 3 is provided with a sheath 6.

Embodiment 2

[0027] Further improvement on the basis of Example 1, an environment-friendly wear-resistant and tensile power cable, the sheath 6 sequentially includes a polyethylene sheath, a low-smoke halogen-free tape, a water-blocking tape and a steel tape from the inside to the outside . The low-smoke and halogen-free wrapping tape is made of low-smoke, halogen-free and flame-retardant glass cloth oxygen-insulating tape; the water-blocking tape is double-sided insulating and water-blocking wrapping tape.

[0028] The insulating layer 22 of the secondary cable 2 adopts a nylon insulating layer, and the sheath 23 adopts a high-density polyethylene protective layer.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com