Connecting type cement unpacking and conveying device

A conveying equipment and connected technology, which is applied in the field of unpacking conveying equipment, can solve the problems of lack of protection mechanism, poor adaptability, improper operation and other problems of the bag breaking device, so as to avoid waste bag entanglement, improve versatility, and protect the equipment from environmental protection sex high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

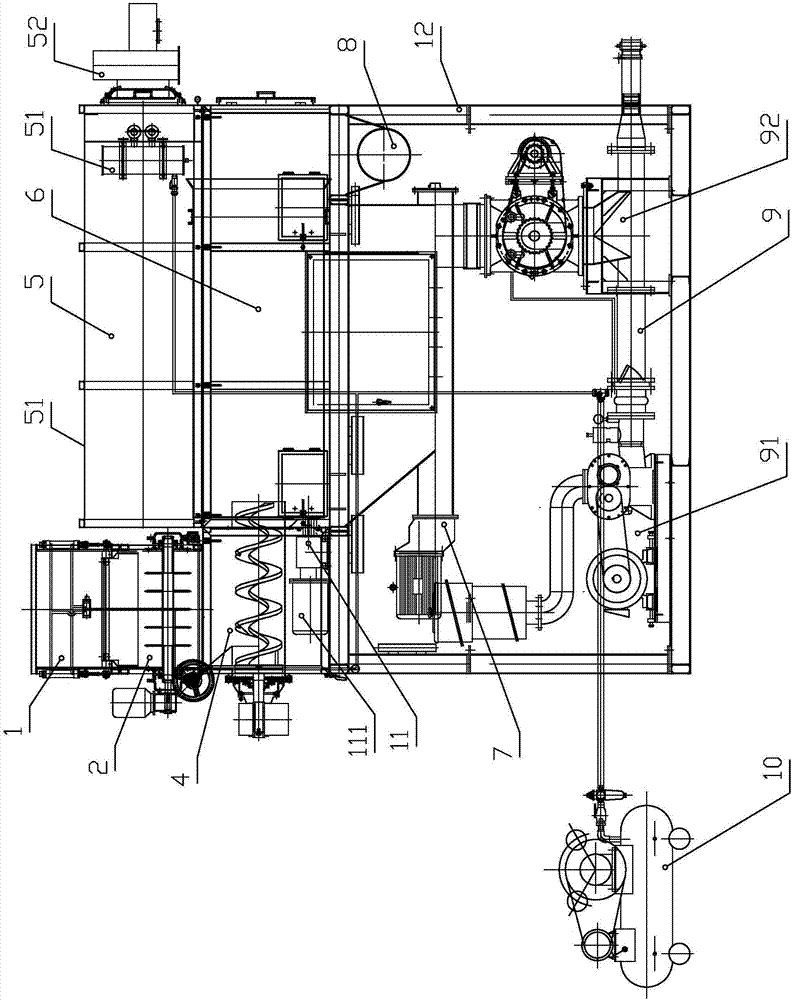

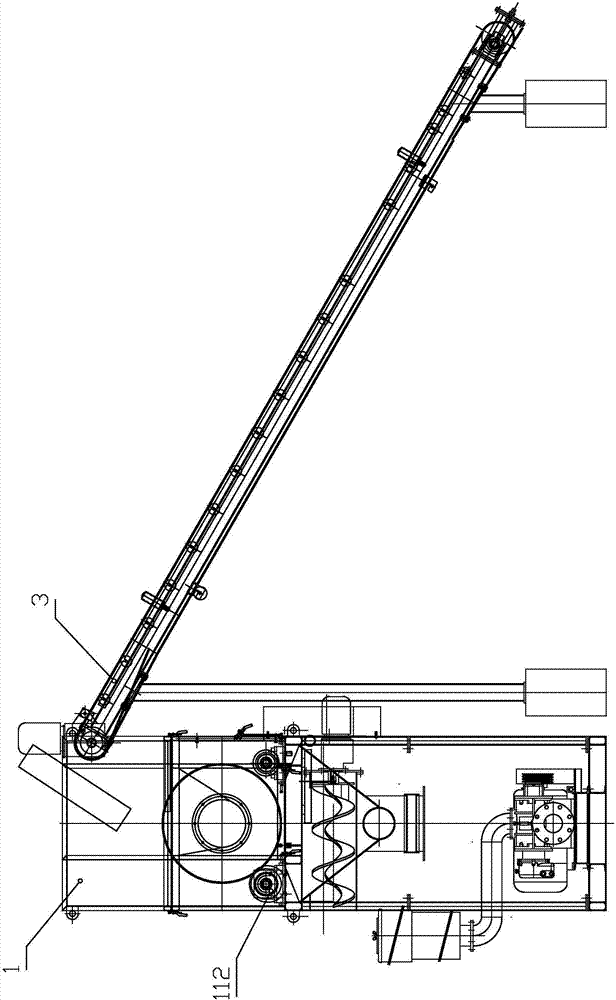

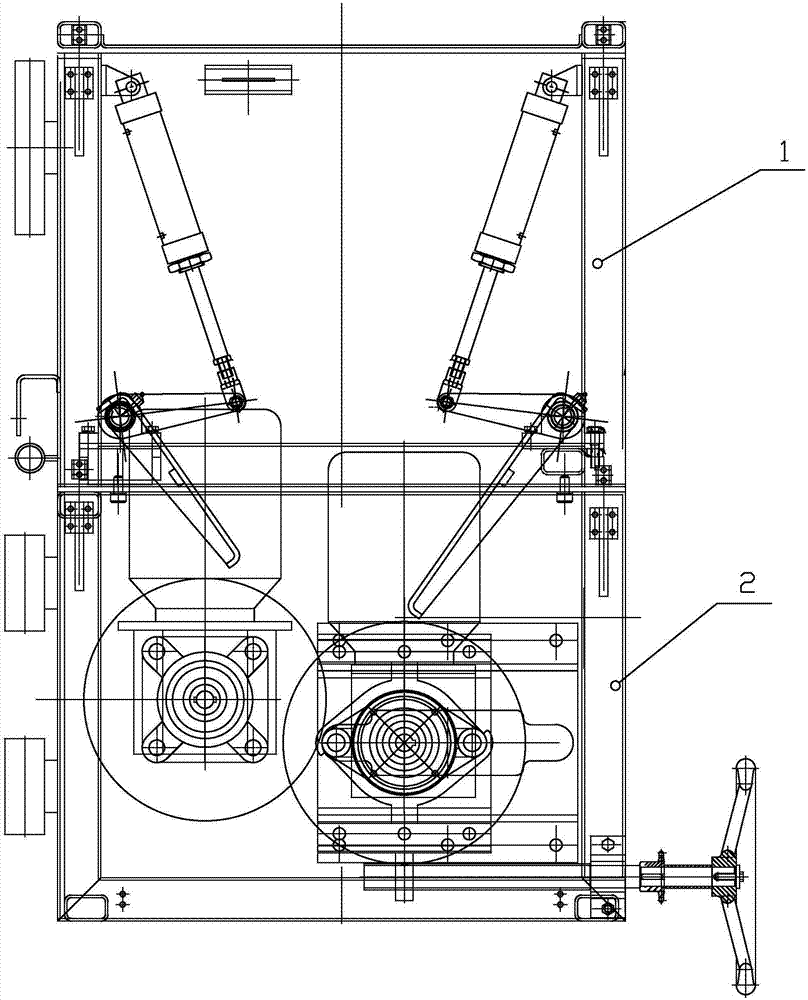

[0055] Refer to the attached figure 1 to attach Figure 13 The connected cement unpacking conveying equipment of the present invention will be described in detail below.

[0056] The connected cement unpacking and conveying equipment of the present invention has a structure including a belt conveyor 3, a hopper assembly 1, a screw extrusion bag breaking device 4, a dust removal system 5, a drum 6, a feeding screw 7, a bag feeding screw 8, and pneumatic conveying System 9, air source system 10, transmission device 11 and main structure 12, the belt conveyor 3 is arranged obliquely and supported on the ground, its upper part is close to the feed hopper assembly 1, and the lower part of the feed hopper assembly 1 is set There is a screw extrusion bag breaking device 4, the lower part of the screw extrusion bag breaking device 4 is fixed on the main structure 12, the transmission device 11 is fixed on the main structure 12, the transmission device 11 and the drum 6 connected, th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com