A kind of near-spherical seed single-grain precision metering device

A kind of seed metering device and near-spherical technology, which is applied in the direction of single seed planter and planter parts, etc., can solve the problems that the single seed precision seeding technology has not been effectively promoted, enters the hole at the same time, and the multi-grain rate increases, etc., to achieve weakening Effects of interaction, ensuring reliability, and reducing porosity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

[0041] In order to further illustrate the technical solution of the present invention, in conjunction with the accompanying drawings, the specific implementation of the present invention is as follows:

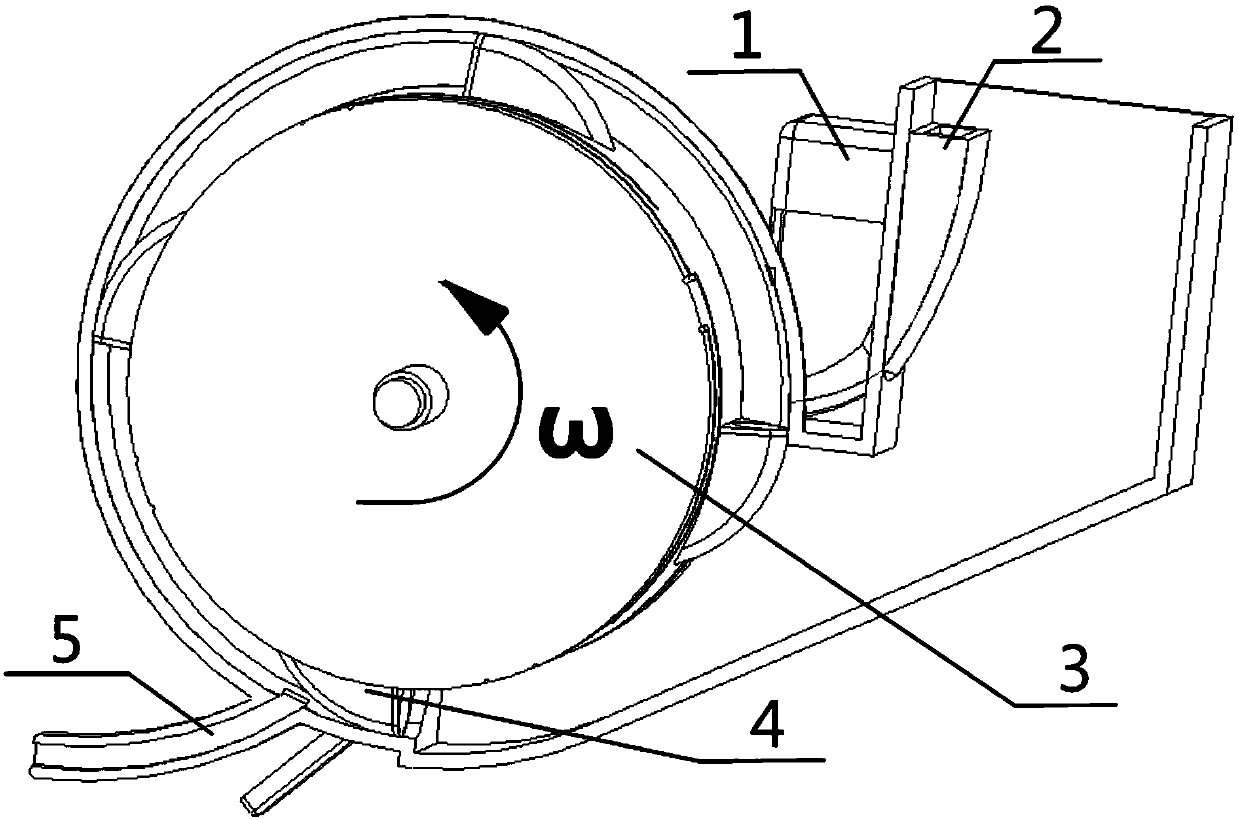

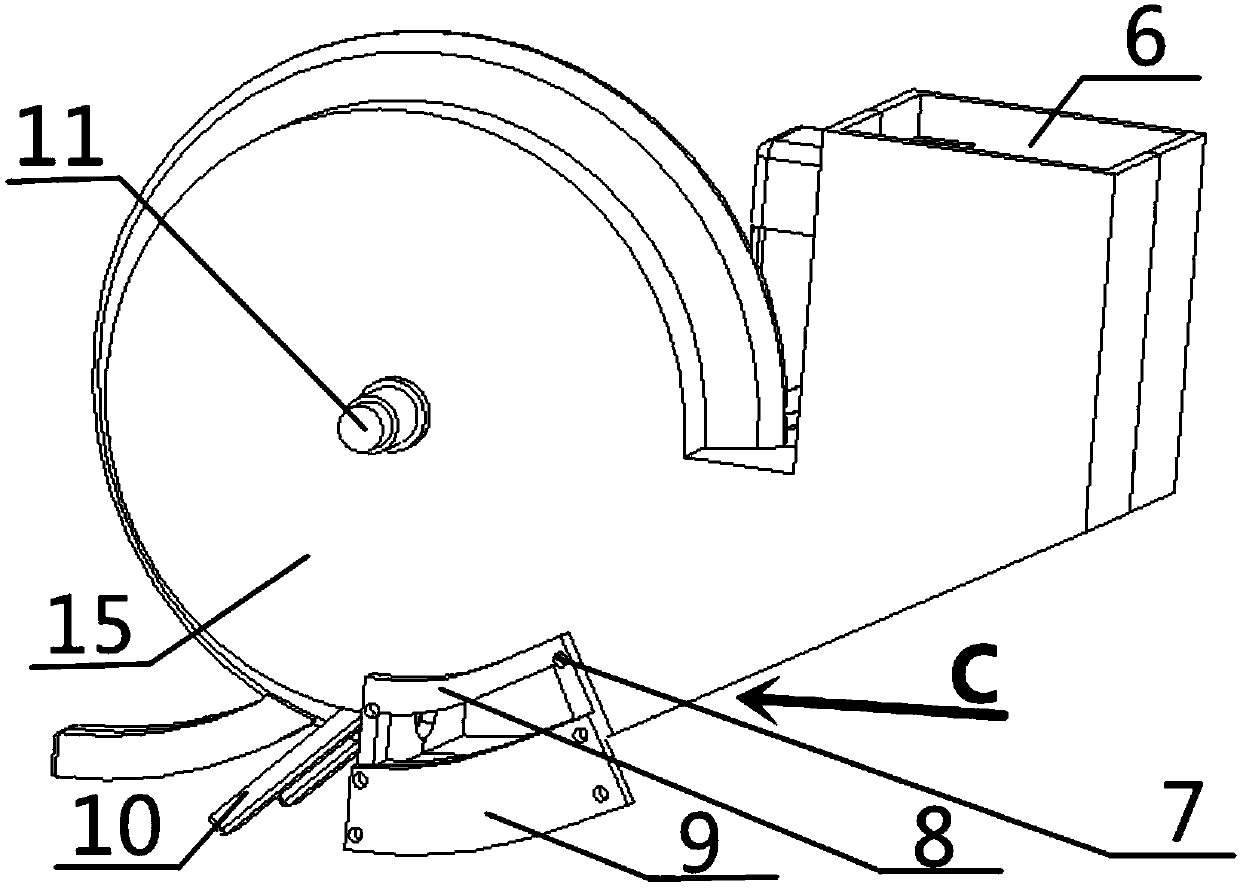

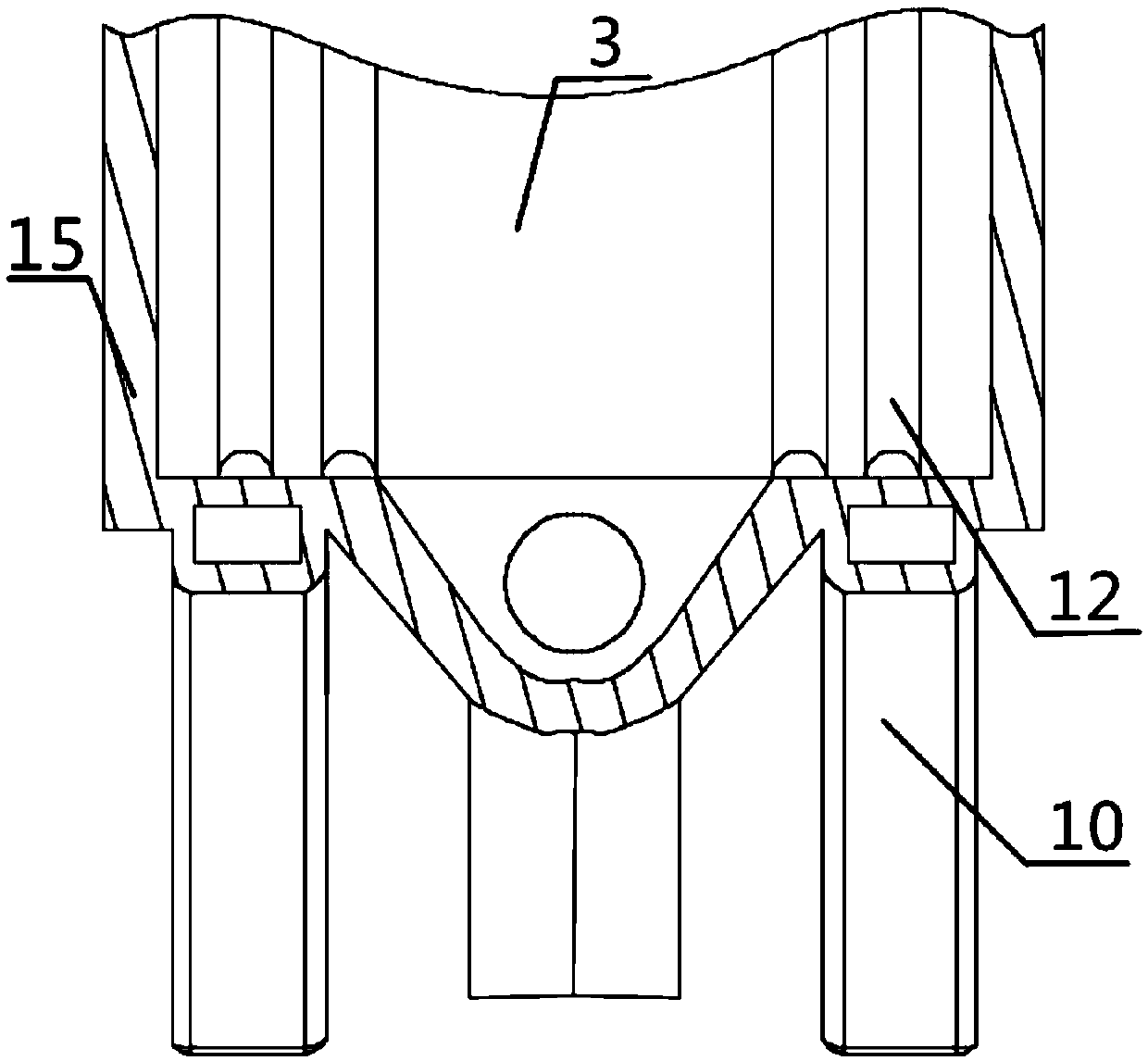

[0042] Such as figure 1 and figure 2 As shown, the present invention provides a kind of near-spherical seed single-grain precision seed metering device, which is composed of compensation device 1, seed divider 2, seeding wheel 3, seed outlet pipe 5, main seed inlet pipe 6, Air intake pipe 10, power input shaft 11, housing 15 form. Seeds enter the housing 15 from the main seeding pipe 6, and the seed wheel 3 rotates in the housing 15 under the drive of the power input shaft 11 and sequentially drives the seeds entering the housing 15 to move in the housing 15, and the nearly spherical seeds Transport to the seed pipe 5 on the other side of the housing 15, and discharge the seeds through the seed pipe 5; during this process, the air intake pipe 10 sends the wind into the hous...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com