Storehouse cleaning robot system for cement storehouse

A robot system and cement silo technology, applied in the field of cement silo cleaning robot system, can solve problems such as improving the efficiency of cleaning silo and reducing the cost of silo cleaning, and achieve the effects of improving the working environment, improving market prospects, and reducing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The technical solutions of the present invention will be further described below through specific implementation manners in conjunction with the accompanying drawings.

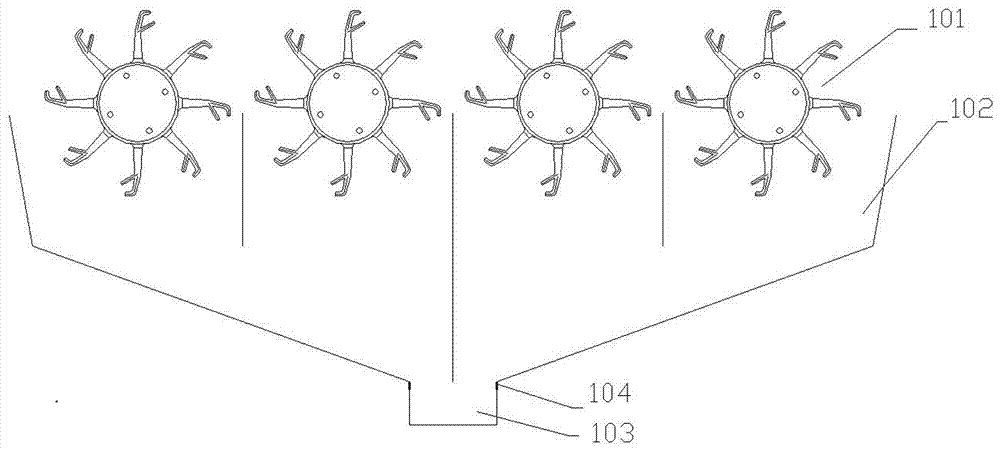

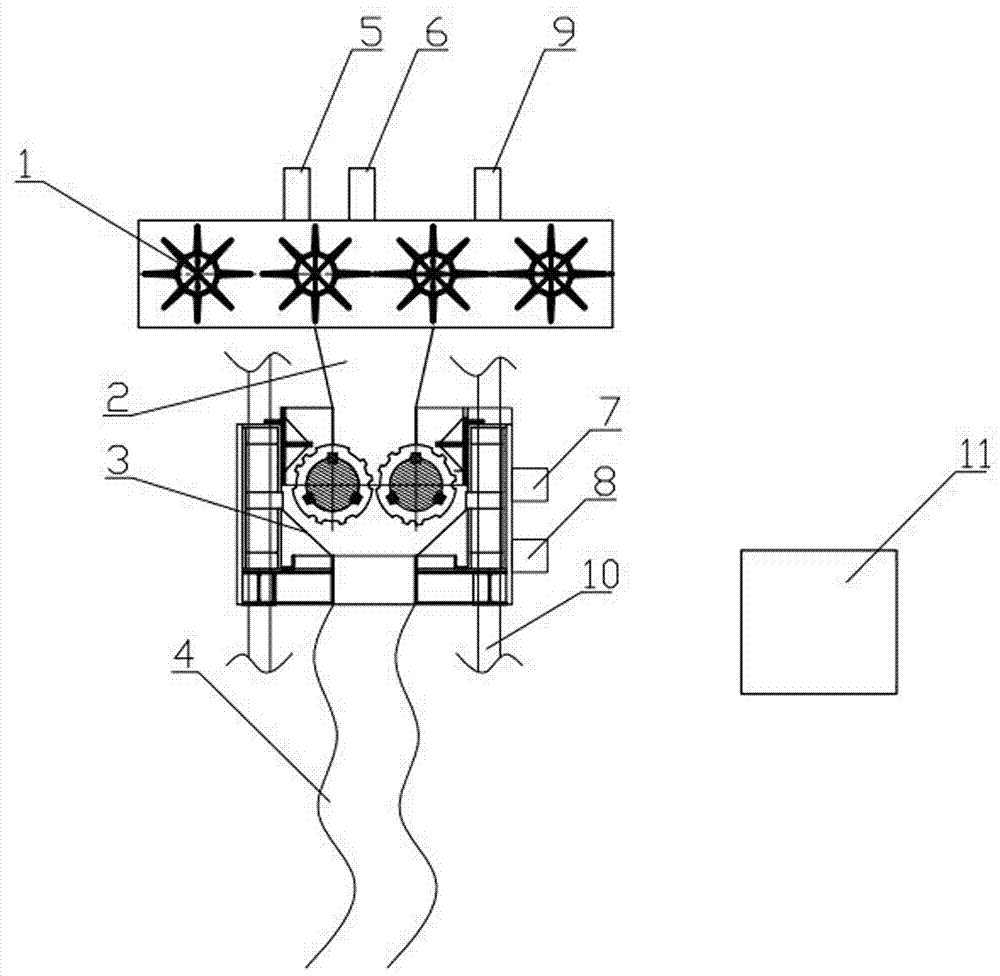

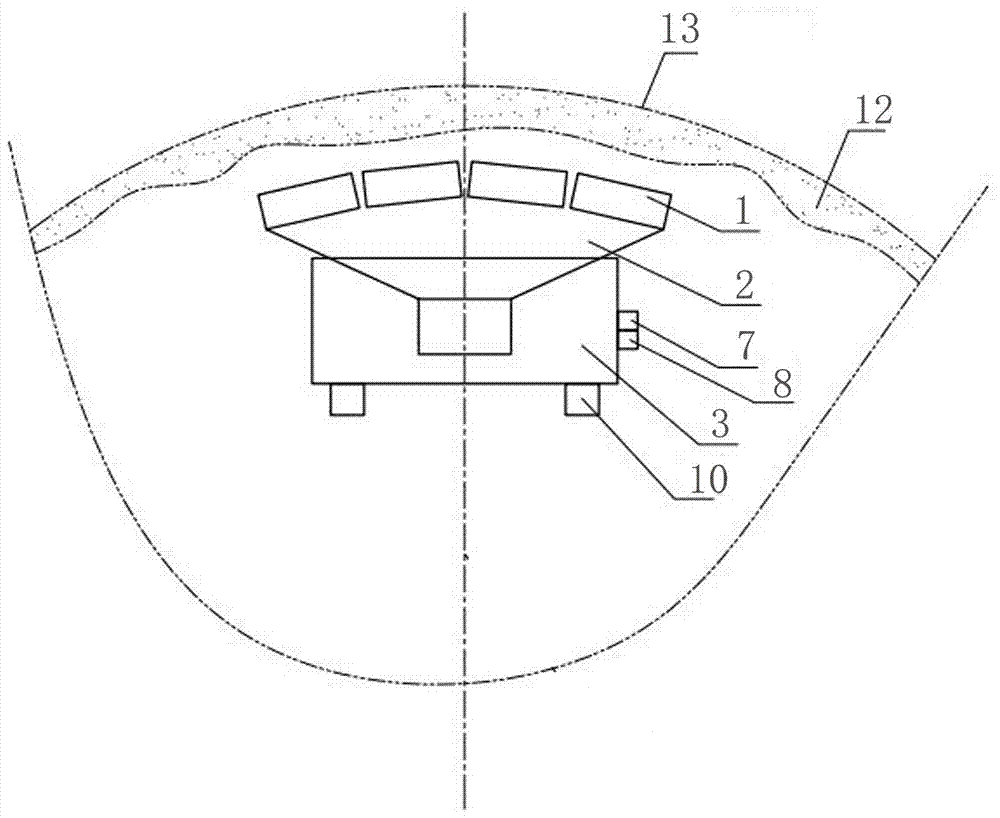

[0031] As shown in the figure, a cement warehouse cleaning robot system includes a warehouse cleaning robot and a sliding track 10, the sliding track 10 is set in the cement warehouse, and the warehouse cleaning robot moves along the sliding track 10 to remove hanging material 12 on the warehouse wall;

[0032] The warehouse cleaning robot adopts a modular design, enters the warehouse from the manhole door 14 on the top of the warehouse, and assembles it in the warehouse; it specifically includes a scraper device 1, a conveying device 2, a crushing device 3, a distance measuring device 7 and a control box 11 , the scraper device 1, the conveying device 2 and the crushing device 3 are connected in sequence, and the scraper device 1 and the crushing device 3 are arranged vertically. Crushing and falling i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com