Method for mounting vehicle former face parts and vehicle

A front face and car technology, applied in the field of installing car front face parts, can solve problems such as relative position deviation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

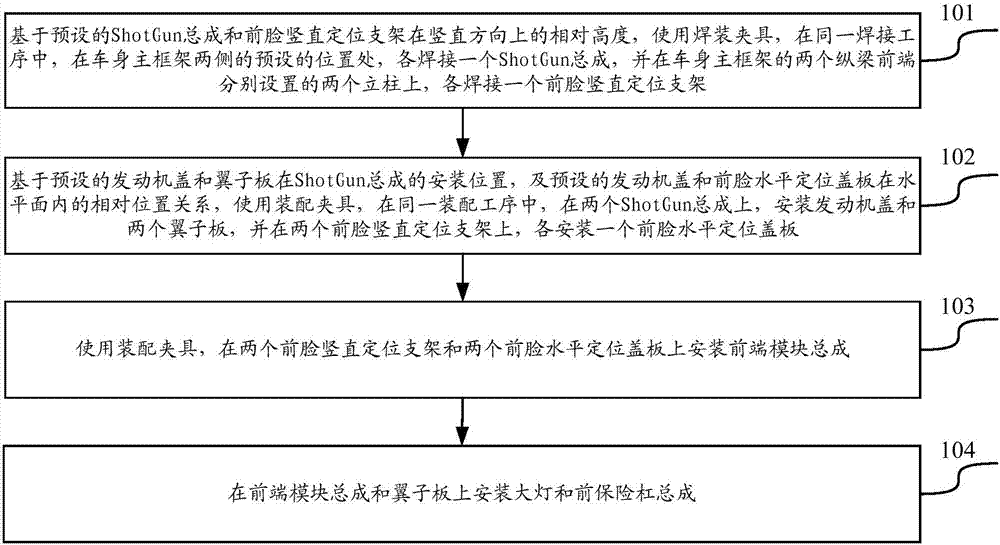

[0062] The invention provides a method for installing the front face parts of an automobile, the flow process of the method is as follows figure 1 As shown, the following steps may be included:

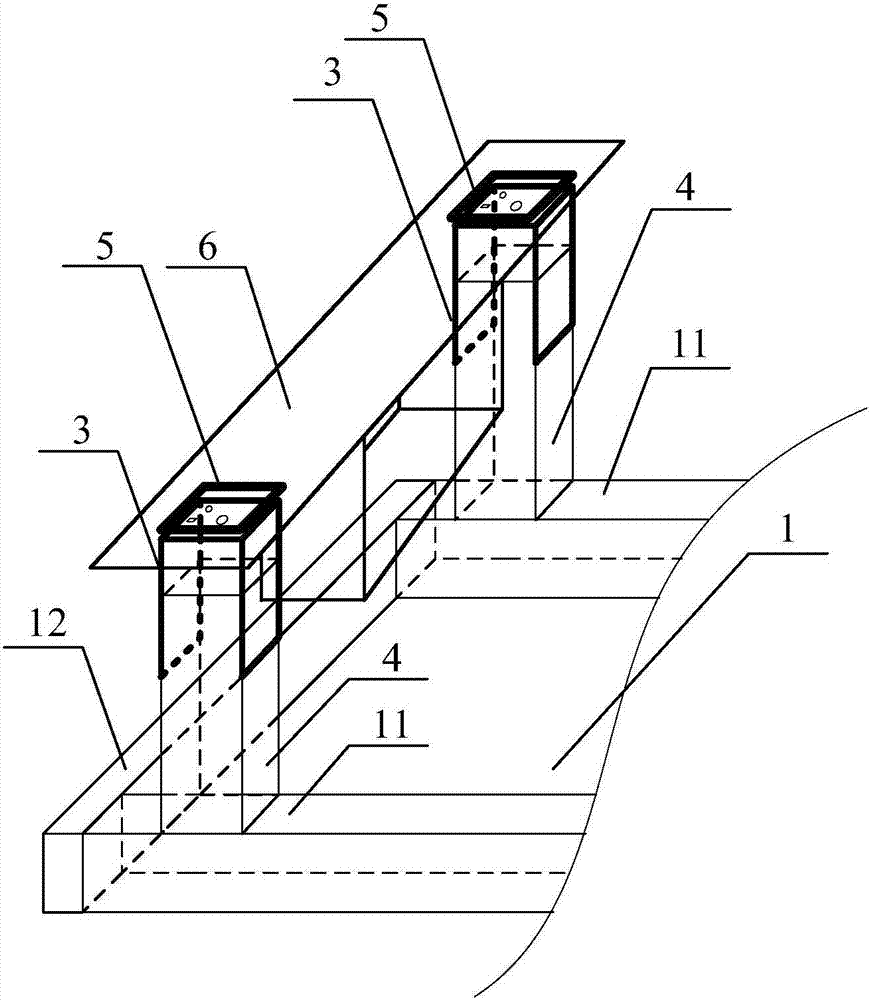

[0063] Step 101, based on the preset relative heights of the ShotGun assembly 2 and the vertical positioning bracket 3 of the front face in the vertical direction, using a welding jig, in the same welding process, the preset heights on both sides of the main frame 1 of the vehicle body position, each welding a ShotGun assembly 2, and on the two columns 4 respectively arranged at the front ends of the two longitudinal beams 11 of the vehicle body main frame 1, respectively welding a front face vertical positioning bracket 3.

[0064] Among them, the welding jig is an auxiliary welding tool, which is used to realize the relative positioning of two or more parts to be welded during the welding process. Specifically, during welding, use the synergy of positioning pins, clamping arms and ...

Embodiment 2

[0088] The present invention also provides an automobile, the front face part of the automobile can be installed using the method described in the first embodiment.

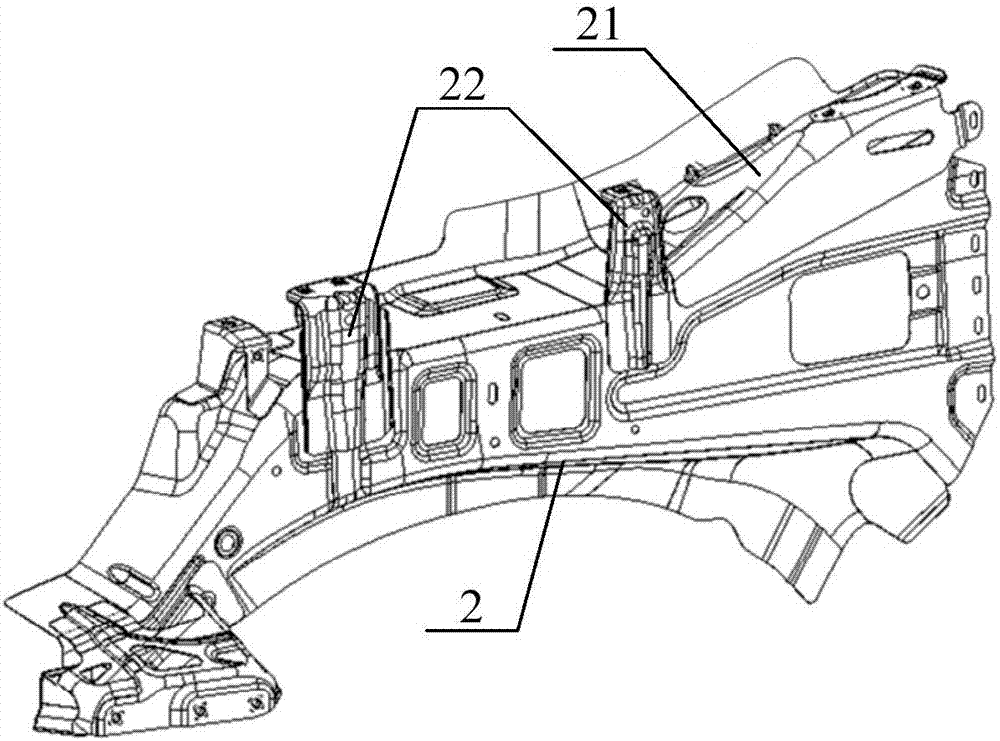

[0089] The car comprises a body main frame 1, an engine cover, a front-end module assembly 6, two ShotGun assemblies 2, two fenders, two front vertical positioning brackets 3, two front horizontal positioning covers 5 and Two headlights, and front bumper assembly, of which:

[0090] Two ShotGun assemblies 2 are installed at the preset positions of the body main frame 1; the front ends of the two longitudinal beams 11 of the body main frame 1 are respectively provided with a column 4, and each column 4 is respectively equipped with a front face vertical positioning bracket 3. Among them, the front face vertical positioning bracket 3 and the ShotGun assembly 2 meet the preset relative height in the vertical direction; the two fenders are respectively installed on the two ShotGun assemblies 2, and the engine cover i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com