High-performance automatic dividing and cutting machine

A slitting machine, high-performance technology, applied in the direction of winding strips, sending objects, conveying filamentous materials, etc., can solve the problems of application limitations, loud noise, serious deformation, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments, but not as a limitation of the present invention.

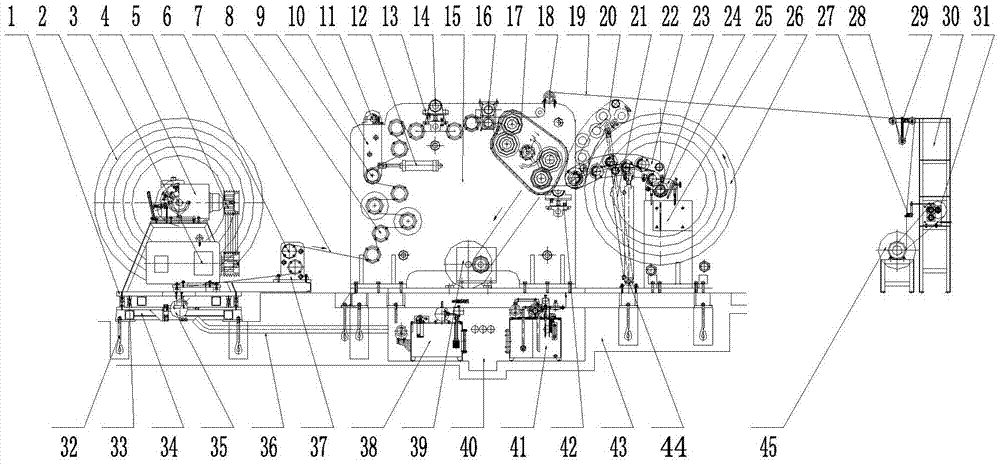

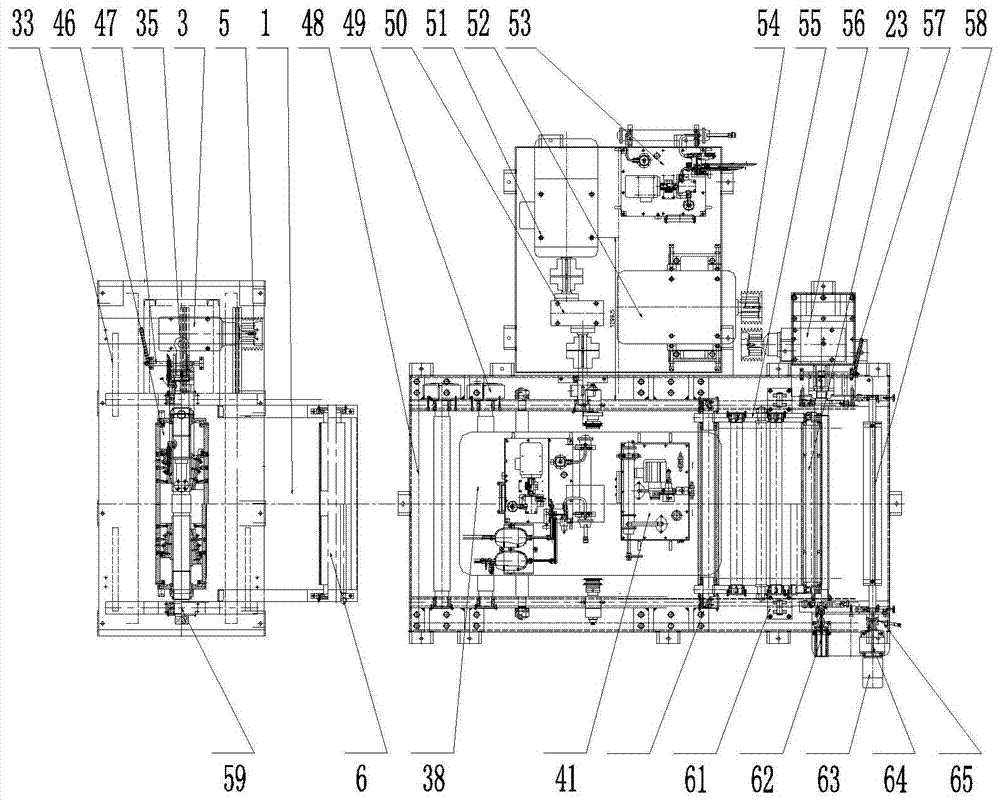

[0023] In view of the unreasonable design of the traditional slitter equipment, the final products slit by the slitter have defects such as unevenness, serious deformation, and mechanical scratches, so the quality of slitting cannot be guaranteed; in addition, the vibration is serious when it is working , high noise and inconvenient operation, so its application is greatly limited; therefore, the present invention provides a high-performance automatic slitting machine, the specific structure of which is as follows figure 1 and figure 2 shown.

[0024] Such as figure 1 and figure 2 , its main structure includes:

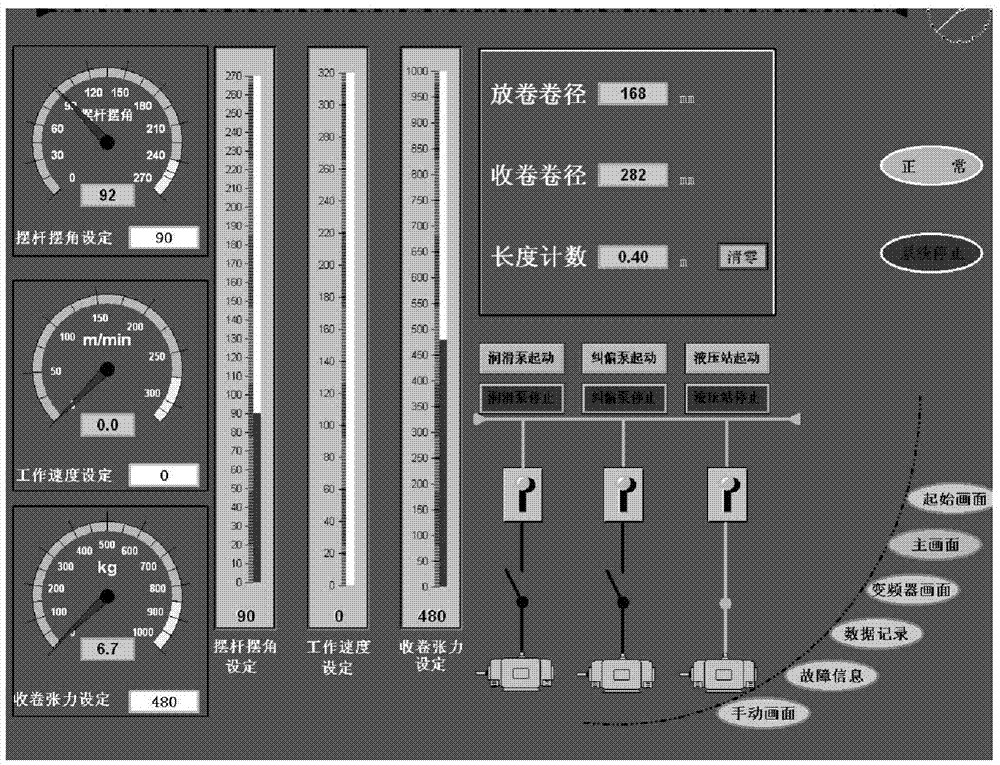

[0025] A device base 43, the said device base 43 is a rectangular parallelepiped hollow frame, on which an unwinding mechanism, a cutting mechanism and a winding Mechanism, as pr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com