Wire arrangement restraint device for warp yarn arrangement

A restraining device and warp yarn technology, which is applied in warping machines, textiles, papermaking, manufacturing tools, etc., can solve problems such as the inability to maintain the yarn arrangement position well, achieve good results, reduce accidents and injuries, and operate in a safe space Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

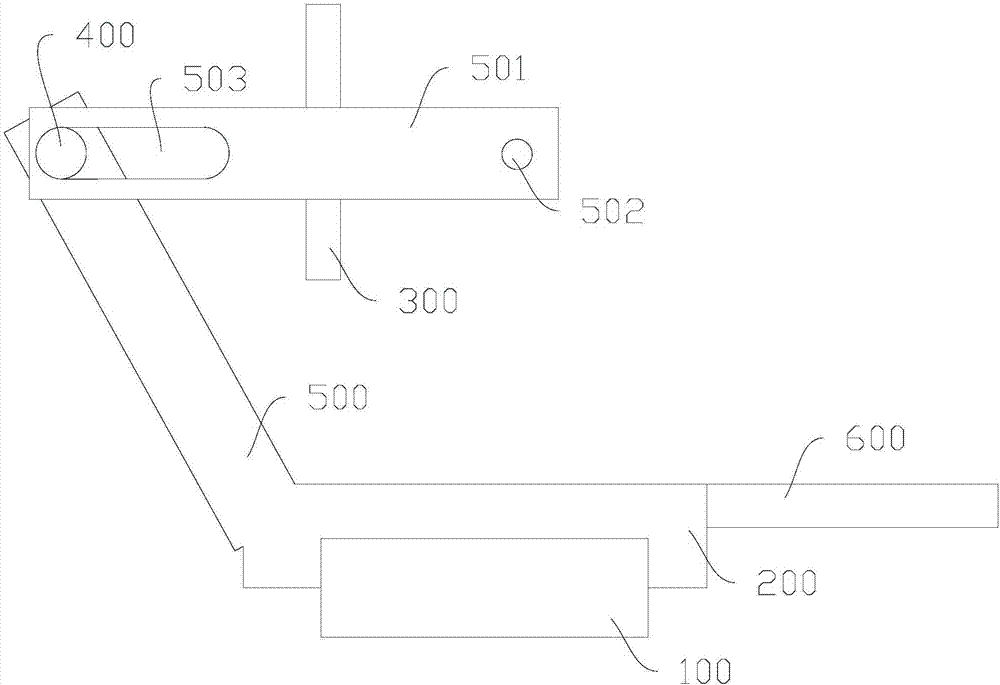

[0027] Such as figure 1 As shown, among them, other views of the cable restraint device can be obtained from the description of this application, so they are omitted. A wire arrangement constraining device for warp finishing, comprising a base 200 installed on a guide rail 100, a grid device 300 arranged above the base 200, and a crimping roller 1400; the grid device 300 is used for yarn The line passes through; the crimping roller I400 is arranged at one end connected to the connecting arm I500 of the base 200; the grid device 300 is arranged at one end connected to the connecting arm II501 of the connecting arm I500, and the connecting arm II501 is along Reverse extension of the yarn advancing direction.

[0028] Wherein, a waist-shaped through hole 503 is also provided at the junction of the connecting arm II501 and the crimping roller I400, and the crimping roller I400 is connected to the connecting arm II501 through the waist-shaped through hole 503, and the waist is Th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com