Cantilever type full-electric walking plate reinstallation vehicle

An all-electric, cantilever technology, applied in the field of manipulators, can solve the problems of high risk factor, high labor intensity and high ground clearance of walking boards, and achieve the effects of low maintenance cost, high degree of automation and simple equipment structure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] Embodiments of the present invention are described with reference to the accompanying drawings.

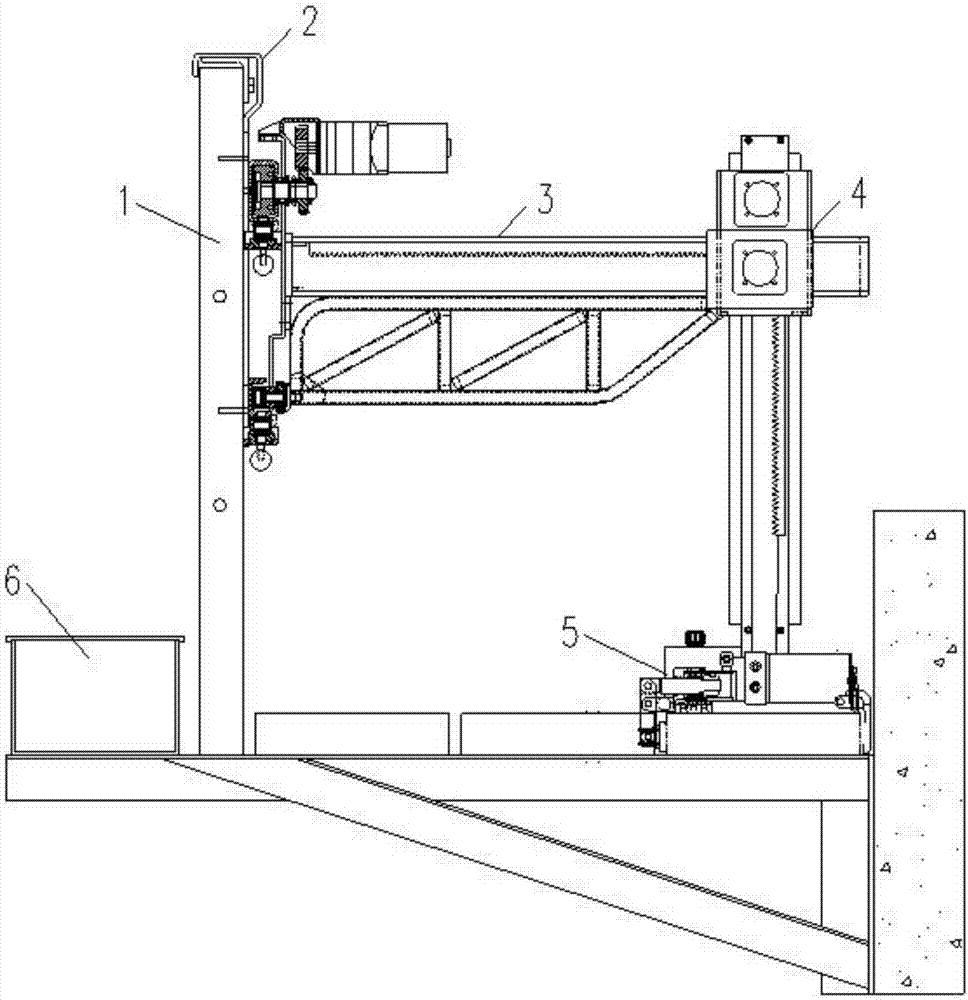

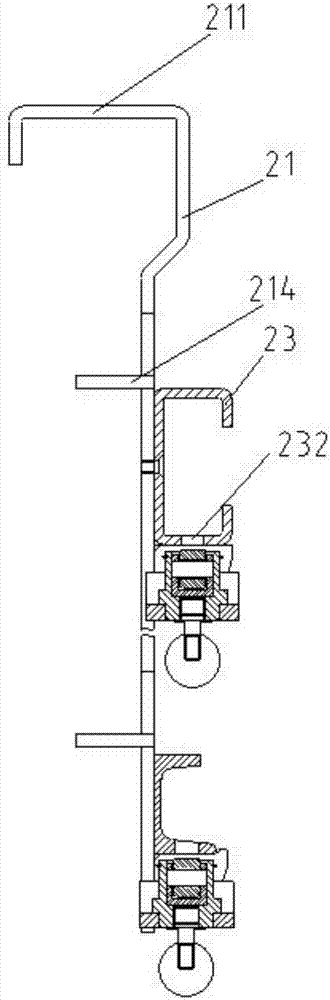

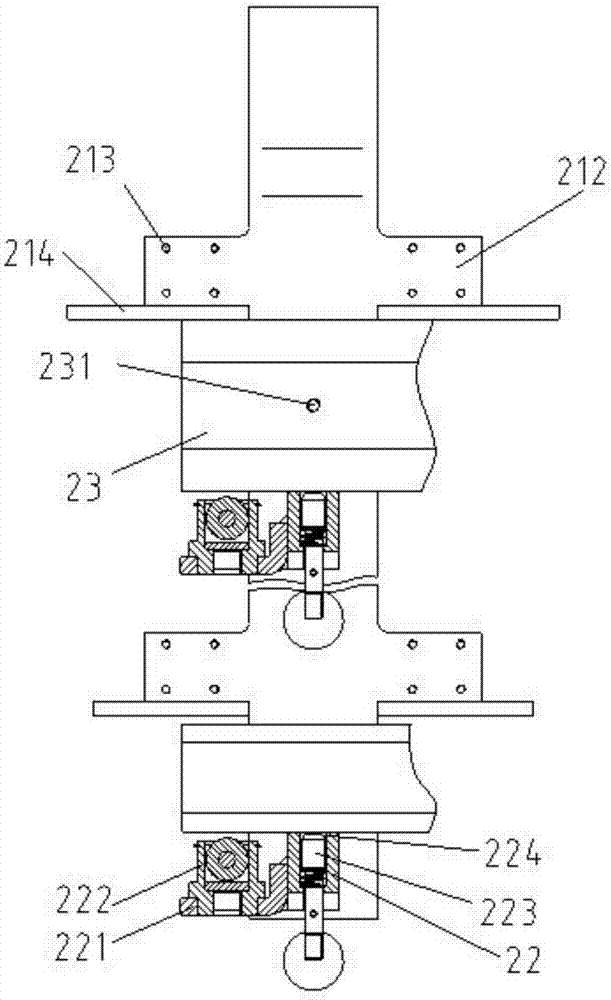

[0025] A cantilever-type all-electric walking board replacement vehicle includes a column 1, a long rail support assembly 2, a cantilever mechanism 3, a moving assembly 4, a clamp 5, and an electric control box 6. There are two or more columns 1 and two or more columns. The top is equipped with a long rail support assembly 2, a cantilever mechanism 3 is installed on the side of the long rail support assembly 2, a mobile assembly 4 is installed on the cantilever mechanism 3, a clamp 5 is installed at the bottom of the mobile assembly 4, and an electric control box 6 is installed. On the outside of the column 1, the long rail support assembly 2 includes a long rail hanging plate 21, the top of the long rail hanging plate 21 is a hook portion 211, and the two sides below the hook portion 211 are provided with an expansion portion 212, and screw holes are provided on the expansi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com