Test bench for high-precision testing of transmission efficiency of RV decelerator

A technology of transmission efficiency and reducer, which is applied in the field of RV reducer transmission efficiency high-precision test bench, can solve the problems of low efficiency, RV reducer testing level and difficulty in debugging, etc., to achieve unique configuration, novel transmission principle, The effect of short commissioning times

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

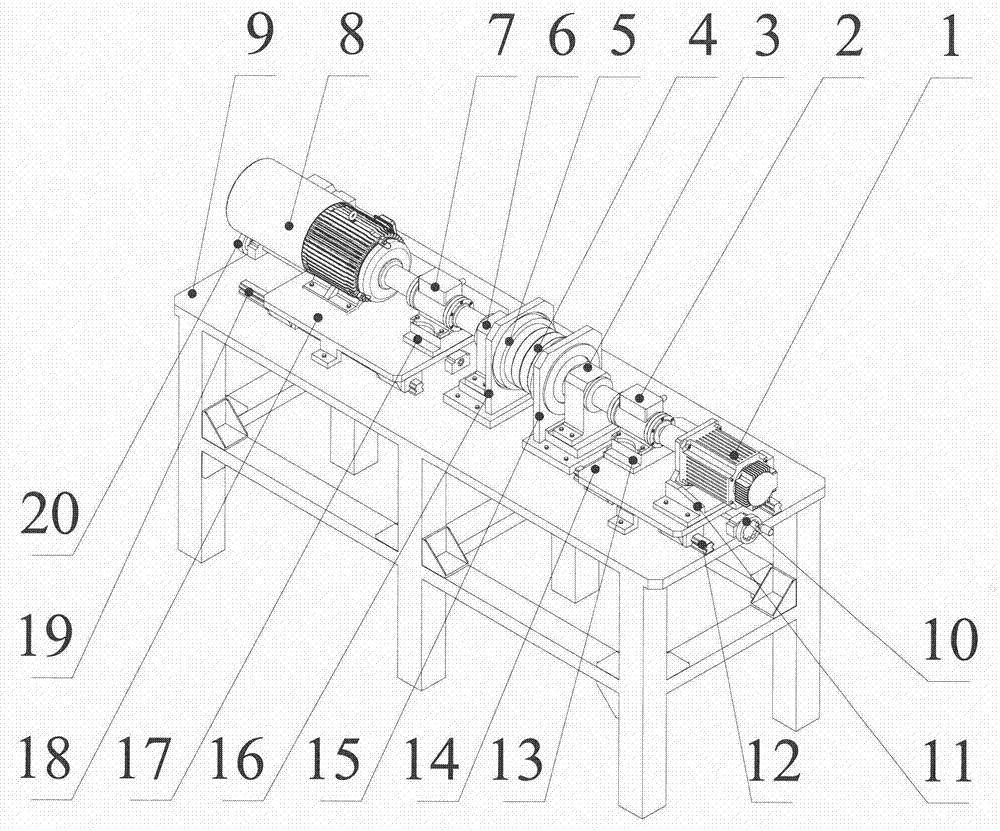

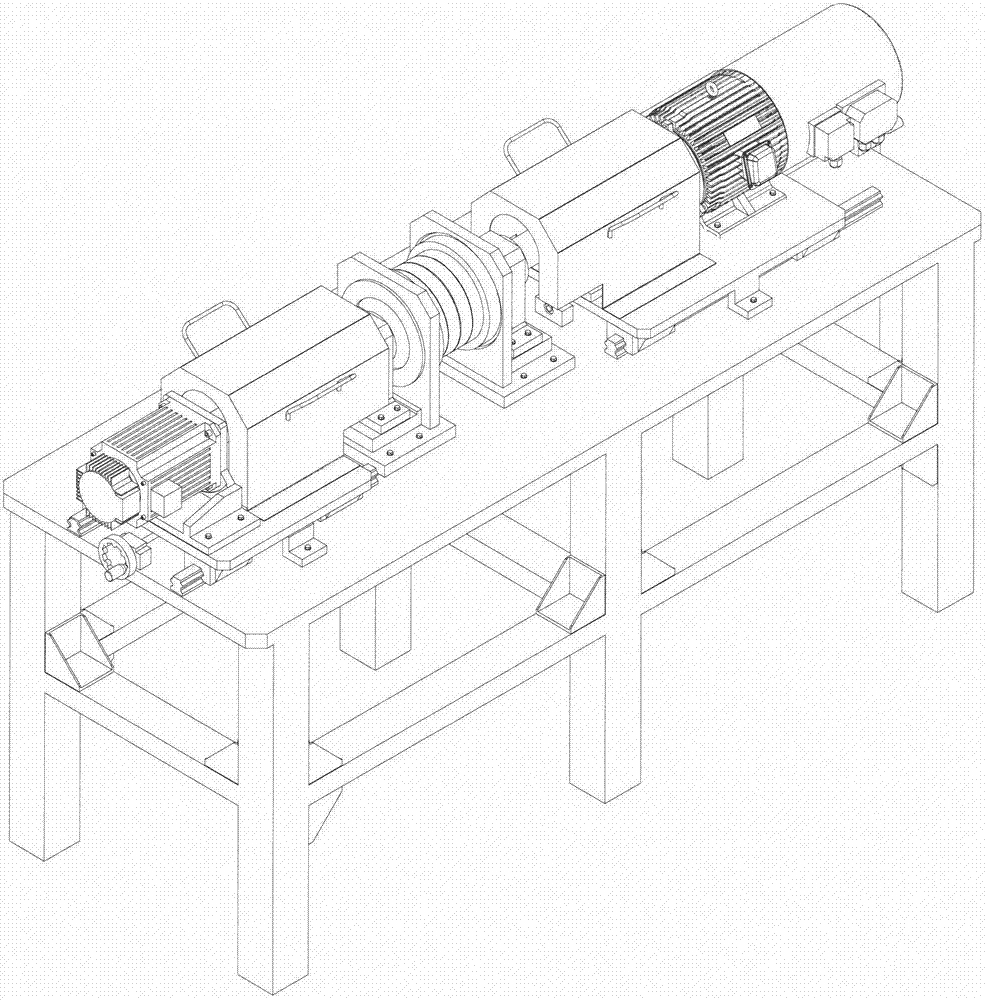

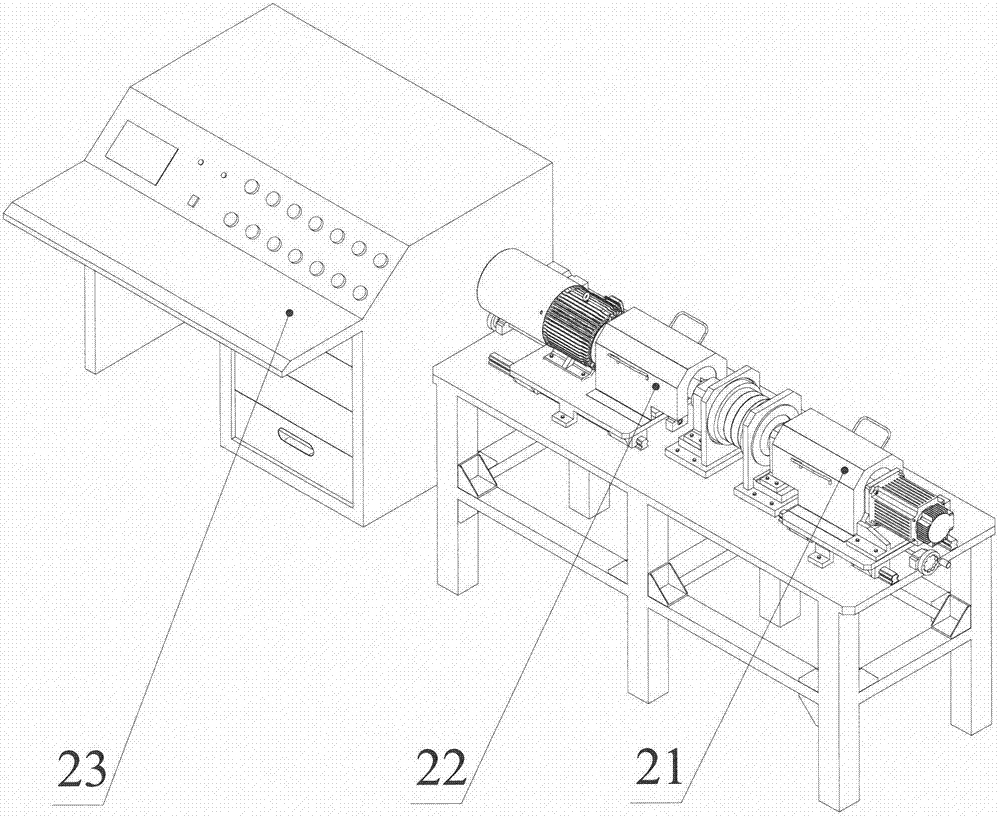

[0030] Embodiments of the present invention are described with reference to the accompanying drawings, below in conjunction with Figure 1-Figure 3 The present invention will be specifically described. A high-precision test bench for transmission efficiency of an RV reducer, including a drive motor 1, an input sensor 2, an input bearing assembly 3, a main reducer 4, an auxiliary reducer 5, an output bearing assembly 6, an output sensor 7, a load motor 8, Bench 9, driving ball screw 10, driving motor support 11, driving guide rail 12, input sensor support 13, driving support 14, main reducer support 15, auxiliary reducer support 16, output sensor support 17, load support Seat 18, load guide rail 19, load ball screw 20, input protection cover 21, output protection cover 22, electrical control cabinet 23.

[0031] The driving motor 1 is installed on the driving motor bracket 11, the output shaft of the driving motor 1 is connected to the input sensor 2, the input sensor 2 is ins...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com