Method for discriminating microstructures of different plain laser master masks

A technology of laser mastering and microstructure, which is applied in the measurement of color/spectral characteristics, etc., can solve problems such as incompatibility, and achieve the effect of simple operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

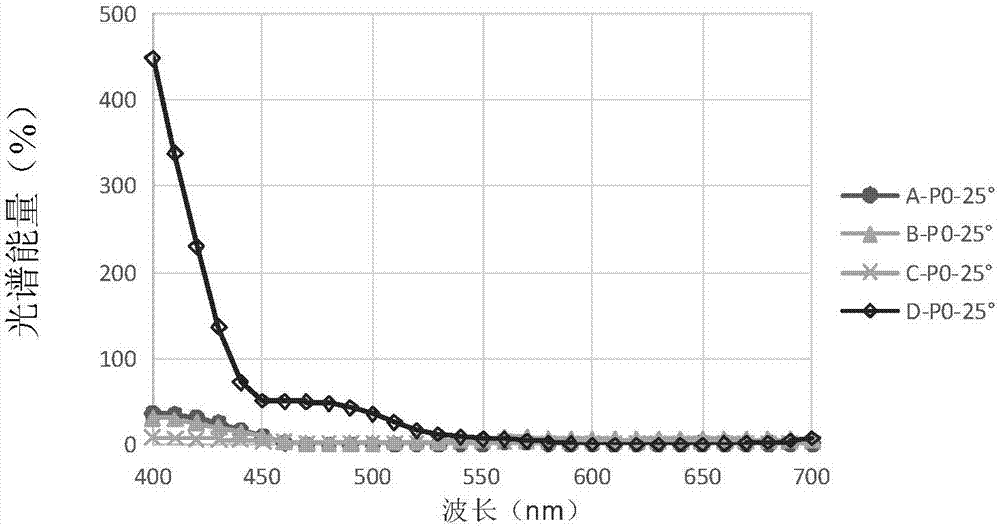

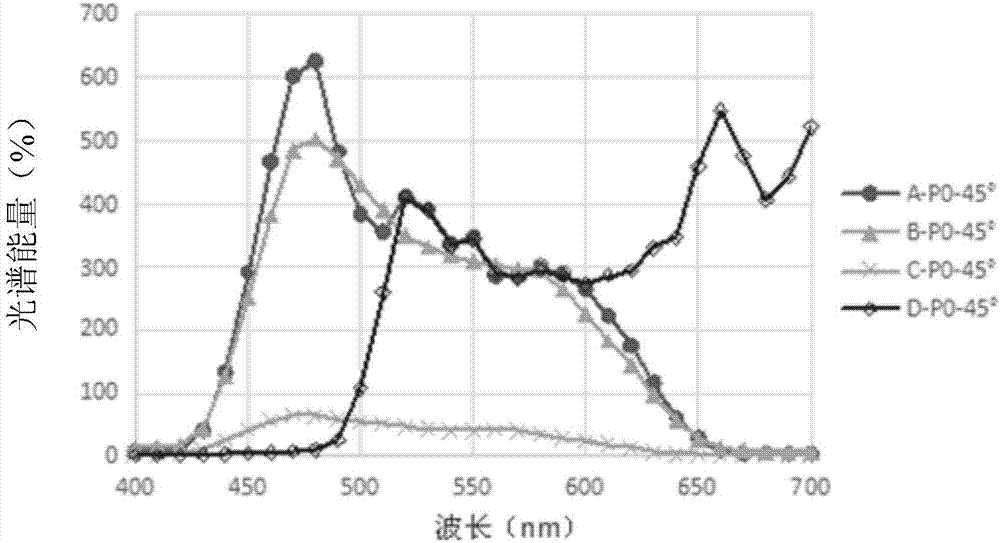

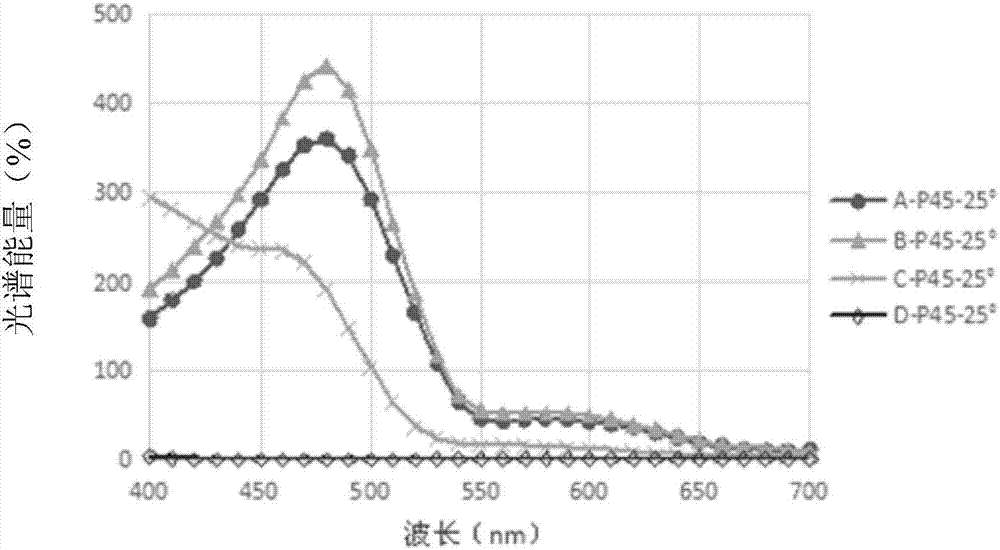

[0031] The invention is a method for discriminating the microstructure of different plain laser masters, using a multi-angle spectrophotometer to measure the chromaticity information and spectrum information on different plain laser masters, which can be used to distinguish and compare the microstructure of different plain laser masters . Fix the position of the master plate, rotate the color measuring instrument, and measure the chromaticity value at different relative angles at the fixed position on the master plate. Correct the initial measurement position of different plain laser masters by chromaticity information, combined with the grating equation, and by comparing the distribution shape of the spectral energy curve in the spectral information and the position of the peak wavelength, a method of using a multi-angle spectrophotometer to distinguish different plain lasers is proposed. A method for mastering microstructures.

[0032] The color measuring instrument adopted...

PUM

| Property | Measurement | Unit |

|---|---|---|

| grating period | aaaaa | aaaaa |

| grating period | aaaaa | aaaaa |

| wavelength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com