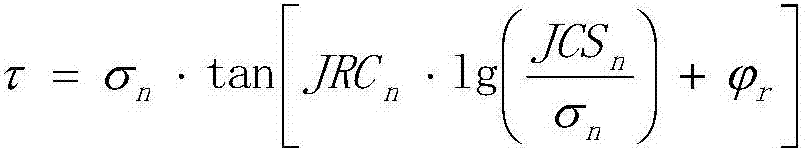

Accurate value obtaining method for shearing strength of engineering rock mass joint

A technology of shear strength and structural plane, which is applied in special data processing applications, instruments, electrical digital data processing, etc., can solve problems such as the inability to accurately measure the shear strength of structural planes of engineering rock mass, and achieve maximum implementation value and social economy The effect of benefit, low cost and accurate value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be further described below.

[0024] A method for accurately determining the shear strength of engineering rock structural planes, comprising the following steps:

[0025] (1) Carry out engineering geological division of engineering rock mass, and carry out rock mass structure analysis in different areas;

[0026] (2) In the selected structure area, through the stability analysis of the rock mass structure, determine the potential slip surface that affects the stability of the engineering rock mass;

[0027] (3) Based on the stability analysis of the rock mass in the selected structure area, determine the potential slip direction on the potential slip surface;

[0028] (4) In the selected structure area, look for the outcrop of the structure surface corresponding to the potential slip surface, and use it as the JRC measurement structure surface;

[0029] (5) On the outcrop of the structural surface corresponding to the potential slip surface...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com