Deep self-learning visual analysis system

A visual analysis and self-learning technology, applied in the field of deep self-learning visual analysis system, to improve production efficiency, analyze data accurately, and reduce production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

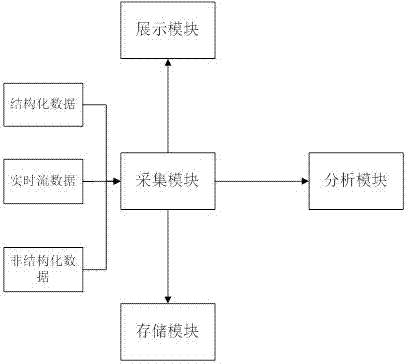

Method used

Image

Examples

Embodiment 1

[0027] Stamping shop - cold rolled steel plate:

[0028] Monitor and analyze the displacement of the steel plate in the video screen, and check whether the equipment stops during operation;

[0029] How many strokes are in the process of running;

[0030] Personnel - Personnel often wait for equipment, and equipment is down for a long time.

[0031] For better detection and analysis, it may be necessary to adjust the installation position of the monitoring equipment or add a new camera, which can fully display the movements of steel plates and personnel.

Embodiment 2

[0033] Press shop - door:

[0034] Detecting and analyzing the position of the mechanical arm in the screen, and detecting and analyzing the displacement of the stamping equipment can judge whether the equipment is working normally, stop overtime alarm, count the time of each stamping process, and count the duration of equipment shutdown.

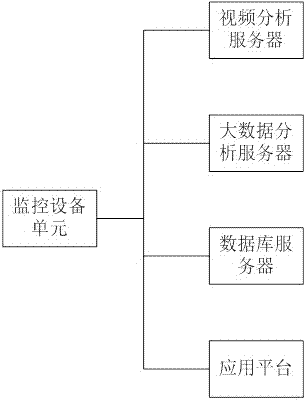

[0035] Such as figure 2 As shown, it also includes a monitoring device unit, a video analysis server, a big data analysis server, a database server and an application platform, and the monitoring device unit includes a public output terminal, and the video analysis server, the big data analysis server, the database server and the application platform are respectively It is connected to the common output terminal of the monitoring equipment unit, the video analysis server is connected to the big data analysis server, the big data analysis server is connected to the database and the server, and the database server is connected to the applica...

Embodiment 3

[0040] Assembly workshop - glass gluing;

[0041] Action decomposition: glass gluing, placing glass, lifting glass and other actions, each action can be analyzed and identified, and the time of each action can be detected and counted, combined with the running time of the equipment, such as the running time of each action of the equipment and Duration, compared with the time point and duration of the worker's action;

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com