Contactor speed closed loop control method based on neural network

A speed closed-loop, control method technology, applied in relays, electrical components, circuits, etc., can solve the problems of contact welding, narrow working voltage range, and affecting the reliability of contactor operation, so as to avoid calculation and improve operation safety Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

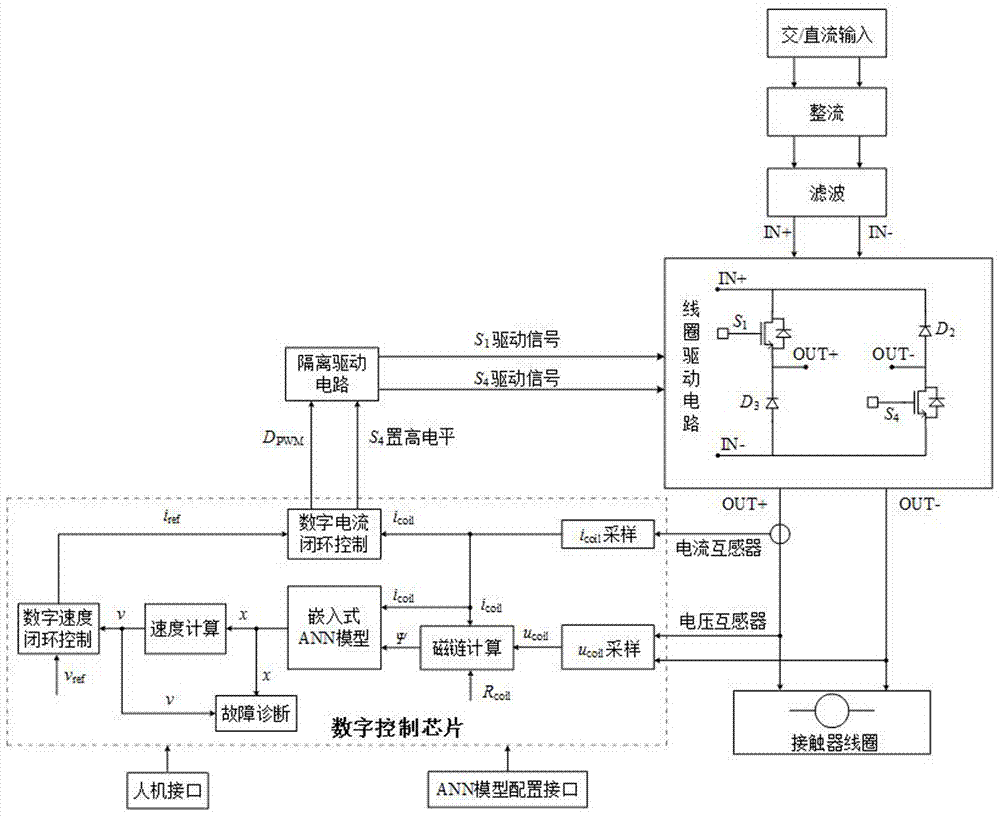

[0026] Such as figure 1 As shown, this embodiment provides a neural network-based contactor speed closed-loop control method, which specifically includes the following steps:

[0027] Step S1: Use the current closed loop as the basic inner loop to flexibly adjust the excitation state of the contactor;

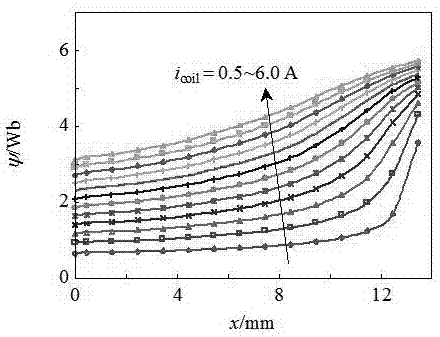

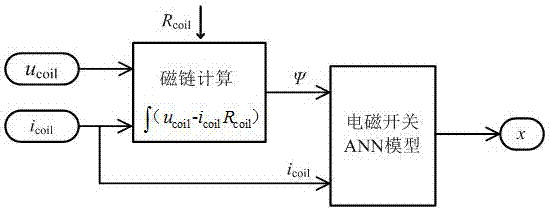

[0028] Step S2: Collect the excitation voltage and excitation current of the contactor, and use the embedded ANN model to calculate the real-time displacement of the moving iron core of the contactor;

[0029] Step S3: use the real-time displacement information to calculate the real-time speed of the moving iron core, and construct the closed-loop control of the speed of the contactor.

[0030] In addition, the real-time calculation of displacement and speed can also realize the diagnosis of common faults of contactors, such as: refusal to open, refusa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com