Plate sucking device for batch positioning in chip welding

A suction plate device and chip welding technology, which is applied in the manufacturing of electrical components, electric solid-state devices, semiconductor/solid-state devices, etc., can solve the problems of difficulty in mass production, low chip efficiency, etc., to ensure accurate positioning and facilitate batch positioning of chips. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

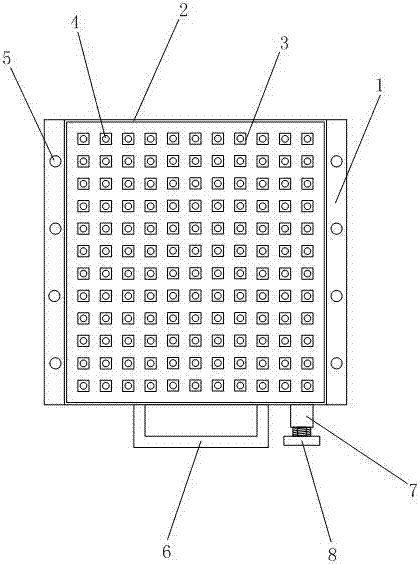

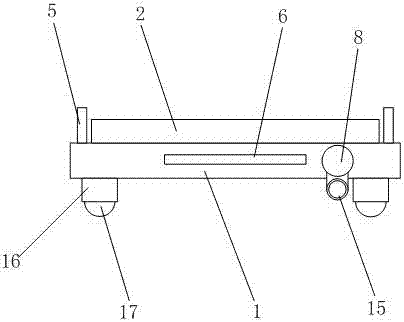

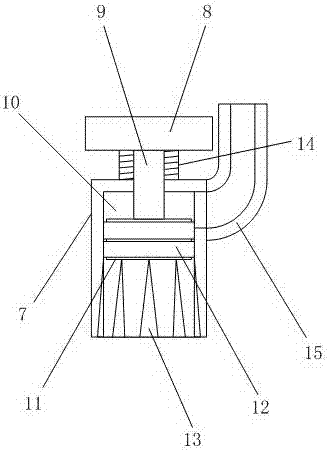

[0013] Such as Figure 1-3 As shown, the suction plate device used for batch positioning during chip welding provided by the present invention includes: a suction plate base 1 , a rectangular frame 2 and a base air valve.

[0014] Wherein, the rectangular frame 2 is installed on the upper part of the suction plate base 1; a support column 16 is provided at the bottom of the suction plate base 1, and a ball 17 is provided at the lower end of the support column 16; There is a chip slot 3; a chip air hole 4 is provided at the bottom of the chip slot 3; a base air cavity communicating with each chip air hole 4 is provided inside the suction plate base 1; Positioning column 5; the base air valve is installed on the side of the suction plate base 1, one end communicates with the base air cavity, and the other end is used to communicate with the vacuum pump of the suction system; on the side of the suction plate base 1 and close to the base air valve A handle 6 is provided.

[0015...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com