Full-automatic circulating type mushroom culture frame

A circulatory, cultivation rack technology, applied in mushroom cultivation, cultivation, plant cultivation and other directions, can solve the problems of difficulty in cultivation and harvesting, low work efficiency, increased danger for staff, etc., and achieve fast and efficient picking and space. The effect of improving utilization rate and reducing labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

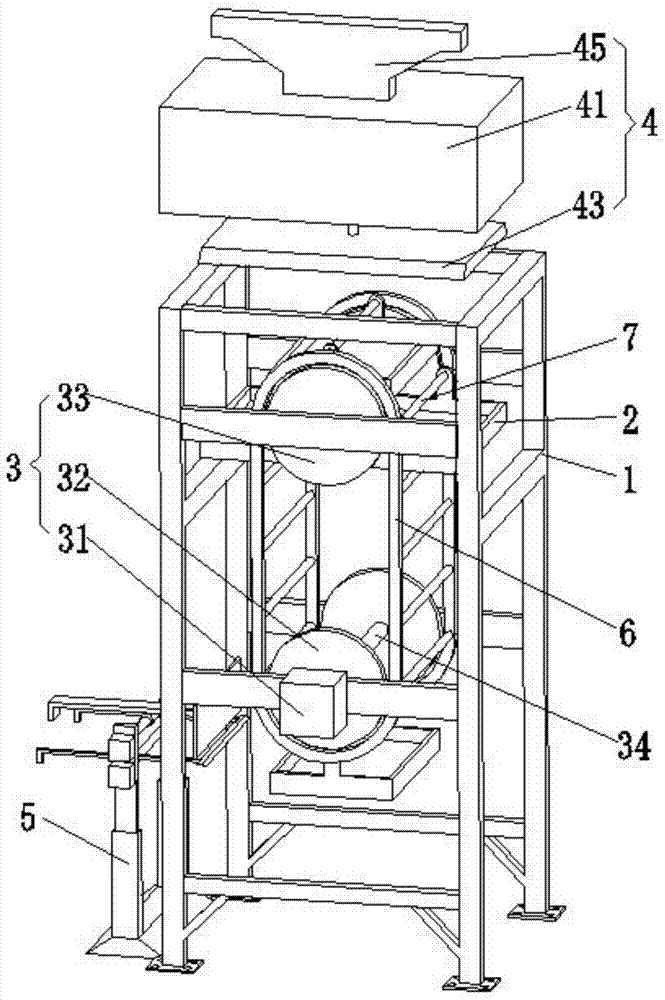

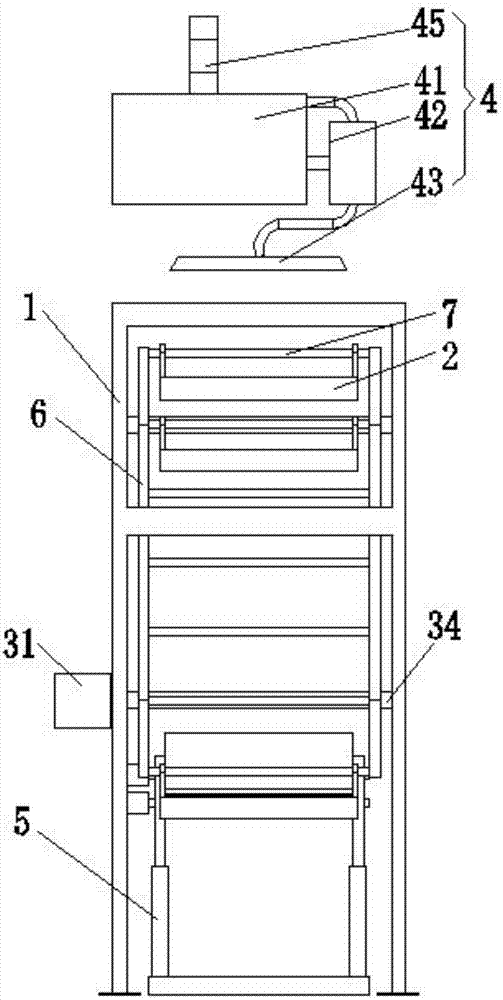

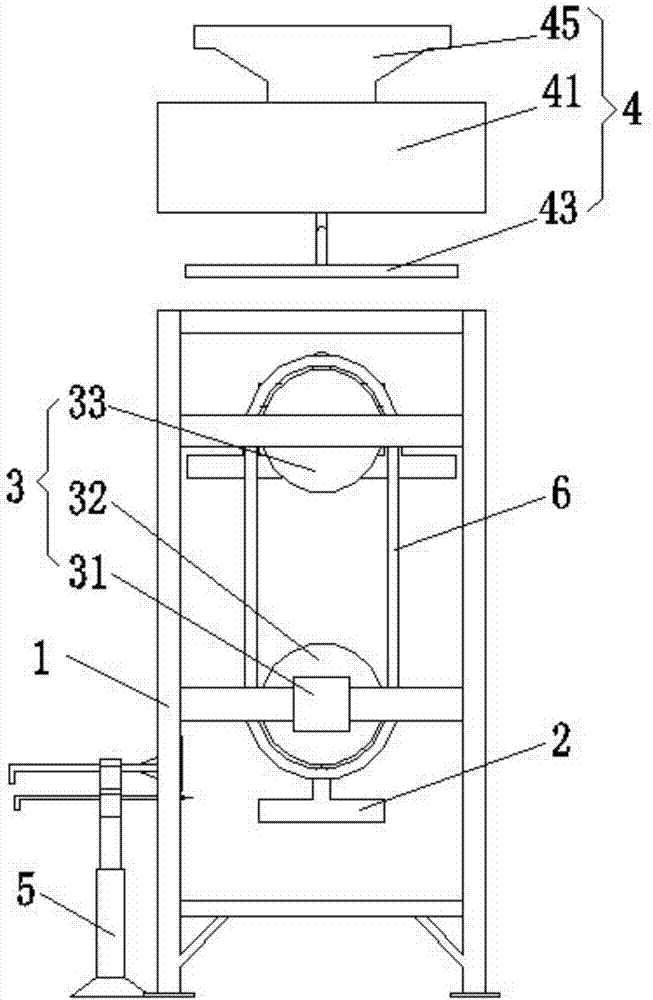

[0026] The present invention is described below in conjunction with accompanying drawing.

[0027] A kind of fully automatic circulation type mushroom cultivation frame of the present invention, refer to Figure 1~8 As shown, it includes a main frame 1, a plurality of cultivation bed frames 2, a driving device 3 installed on the main frame 1, a sprinkler device 4 and a harvesting device 5 installed above the top of the main frame 1; Two mutually symmetrical chains 6 are symmetrically installed respectively; a plurality of suspension shafts 7 in a horizontal state are evenly arranged between the two chains 6, and the two ends of the suspension shafts 7 are fixedly connected to the chains 6; The bottom of each suspension shaft 7 is hinged with a cultivation bed frame 2; the cultivation bed frame 2 includes a cuboid bed frame body 21 with an open upper end, and the inner bottom end of the bed frame body 21 is provided with a circulating conveyor belt 22 , the conveyor belt 22 is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com