Intelligent aquarium control system

An intelligent control system, aquarium technology, applied in the control/regulation system, non-electric variable control, simultaneous control of multiple variables, etc., can solve the problems of spending a lot of time, single function of aquarium, etc., to reduce energy and save energy , the effect of prolonging the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be further described below in conjunction with accompanying drawing:

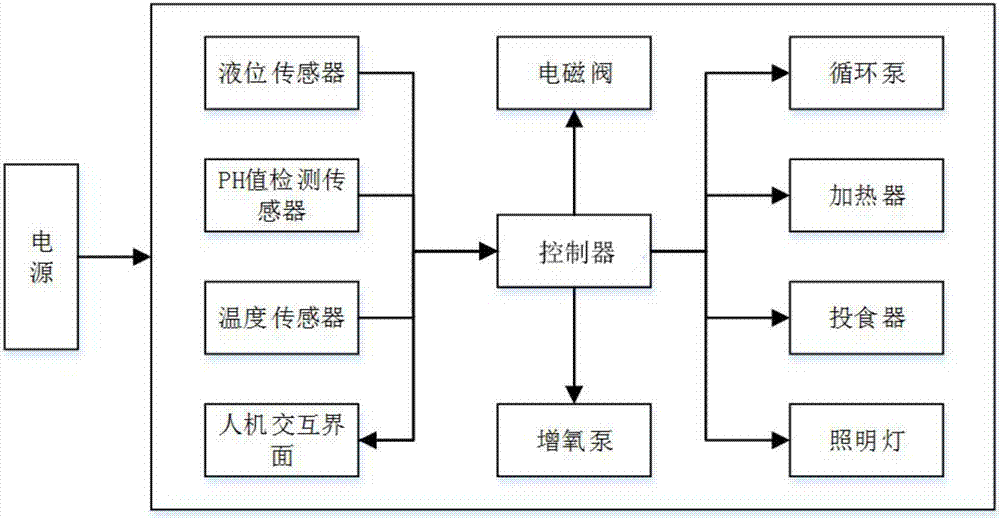

[0017] Such as figure 1 Shown: the present invention is made up of power supply, liquid level sensor, PH value detection sensor, temperature sensor, man-machine interface, controller, electromagnetic valve, aeration pump, circulation pump, heater, feeder and lighting lamp, described The signal output ends of the liquid level sensor, the PH value detection sensor and the temperature sensor are connected to the signal input end of the controller, and the human-computer interaction interface is transmitted with the control signal of the controller through the industrial Ethernet protocol The control output terminals of the controller are respectively connected with the solenoid valve, the aeration pump, the circulation pump, the heater, the feeder and the lighting lamp.

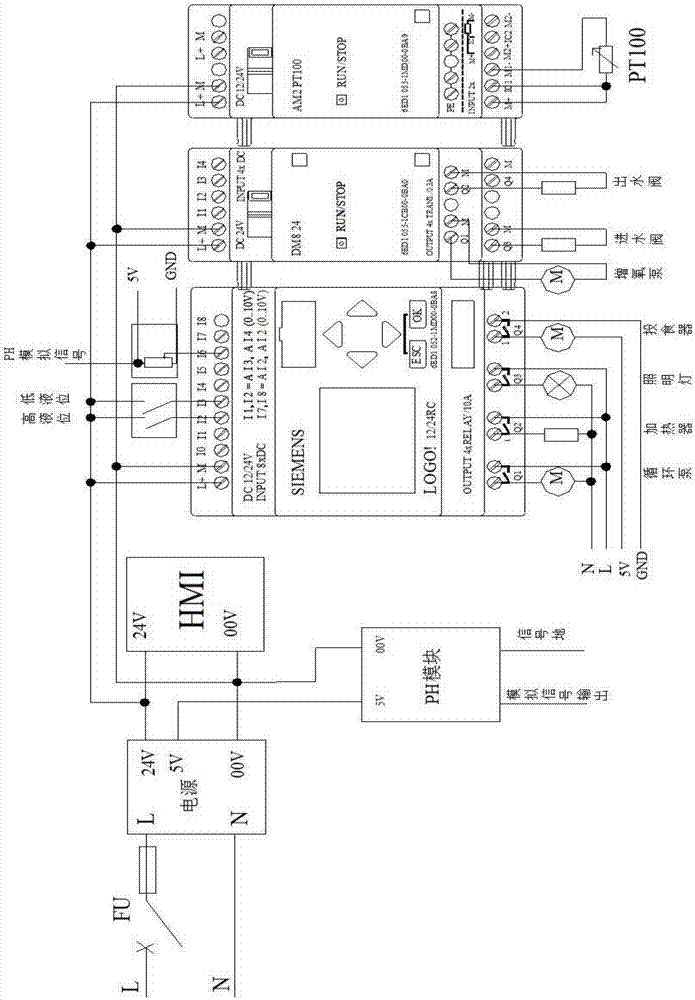

[0018] All power energy is provided by 24V / 5V switching power supply, Siemens core controller Logo! As t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com