Automobile pipe port forming equipment and port forking method thereof

A technology for forming equipment and pipe fittings, applied in forming tools, metal processing equipment, manufacturing tools, etc., can solve the problems of high cost and low efficiency, and achieve the effect of high processing efficiency, low labor cost and good forming stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

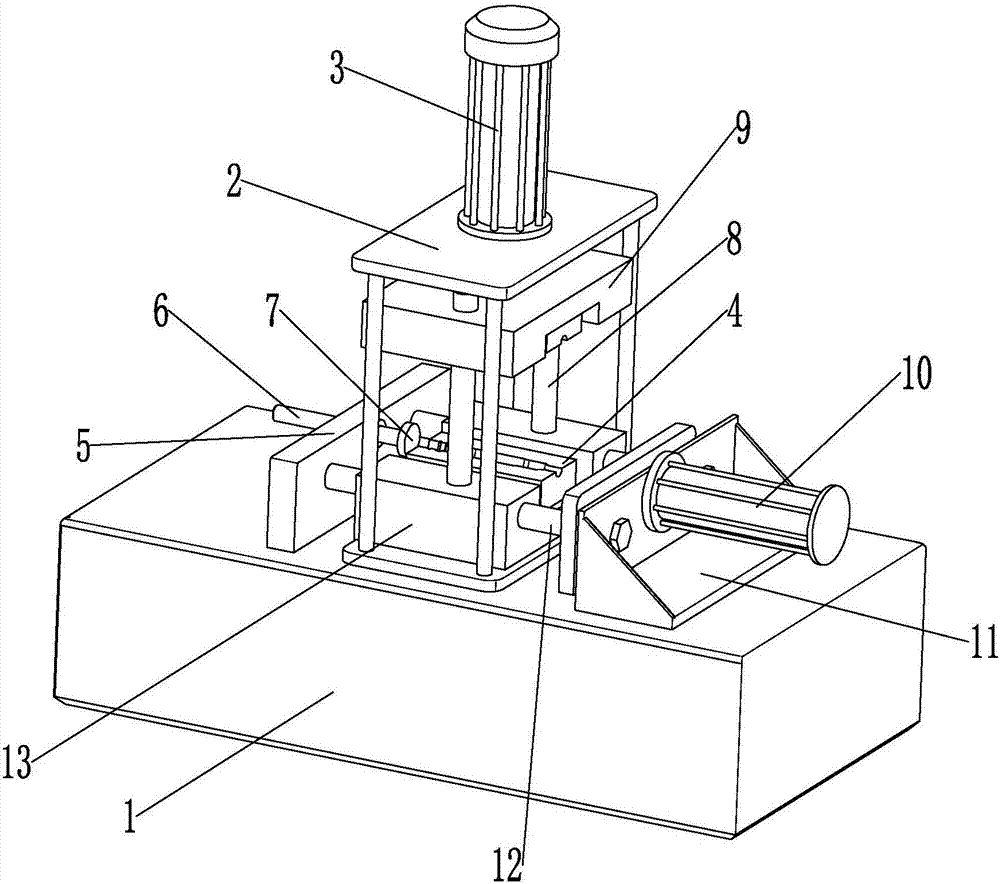

[0036] The automobile pipe fitting port forming equipment disclosed in this embodiment, such as image 3 As shown, it includes a frame 1, a mold frame 2, a forming mold 4 and a pressing mechanism, the mold frame 2 is fixedly installed on the frame 1, the mold frame 2 is provided with a mold installation cavity, and the forming mold 4 is installed in the mold installation cavity, The pressing mechanism is arranged on the side of the molding die 4 .

[0037] Such as image 3 with Figure 5 As shown, the formwork 2 includes an upper mounting plate 21, a lower mounting plate 23, and four columns 22 corresponding to the upper and lower spacing distances. The lower mounting plate 23 is fixedly installed on the top of the frame 1, and the four columns 22 are vertically distributed on the lower mounting plate. The surroundings and the bottom end of the plate 23 pass through the lower mounting plate 23 and are fixedly connected with the frame 1. The upper mounting plate 21 is fixedly i...

Embodiment 2

[0041] Embodiment two, automobile pipe fitting port forming method, such as image 3 , Figure 5 with Figure 8 As shown, insert the mandrel into the automobile pipe fitting to be formed, make the small diameter section of the stepped shaft 17 protrude from the necking section of the automobile pipe fitting to be formed, and the bulging block 18 is located in the inner cavity corresponding to the forming end of the pipe fitting to be formed, and then Place the pipe fittings to be formed into the lower mold cavity of the lower mold 42, and the lifting drive mechanism drives the upper mold 41 to move downward until the upper mold 41 and the lower mold 42 are combined to fill the automobile pipe fittings in the mold cavity and press them tightly to fix them. The jacking block 7 leans against the end of the molding die corresponding to the forming end of the pipe fitting, the movable jacking block 16 leans against the end of the small diameter section of the stepped shaft 17, and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com