Load-sharing decorative tile sticking and building adjustable connector

A technology of connectors and decorative bricks, applied in the direction of covering/lining, construction, building construction, etc., to achieve the effect of increasing firmness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

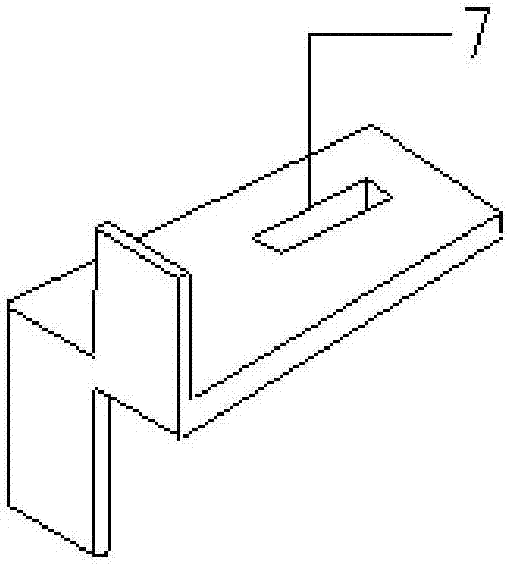

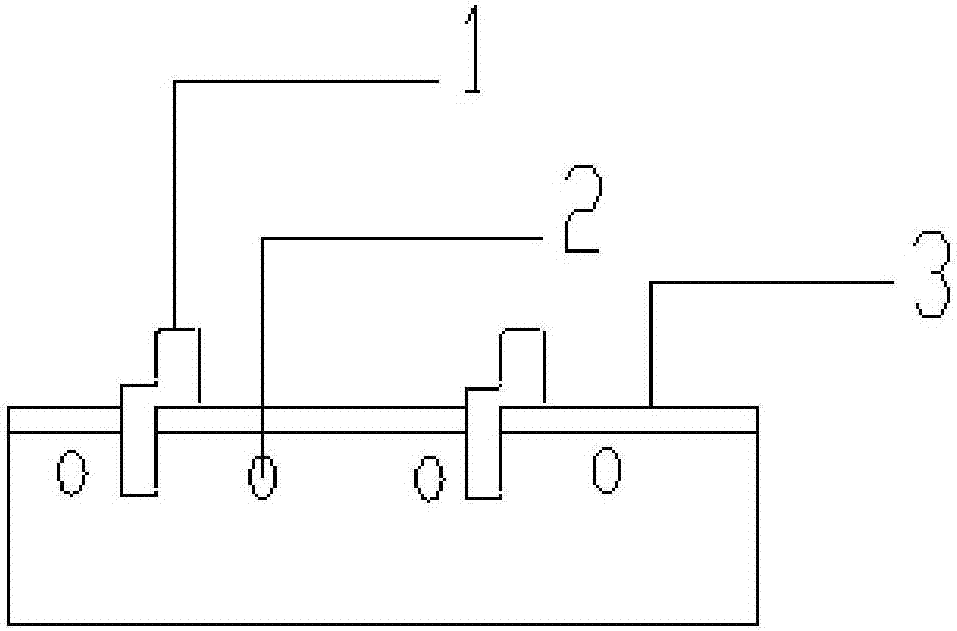

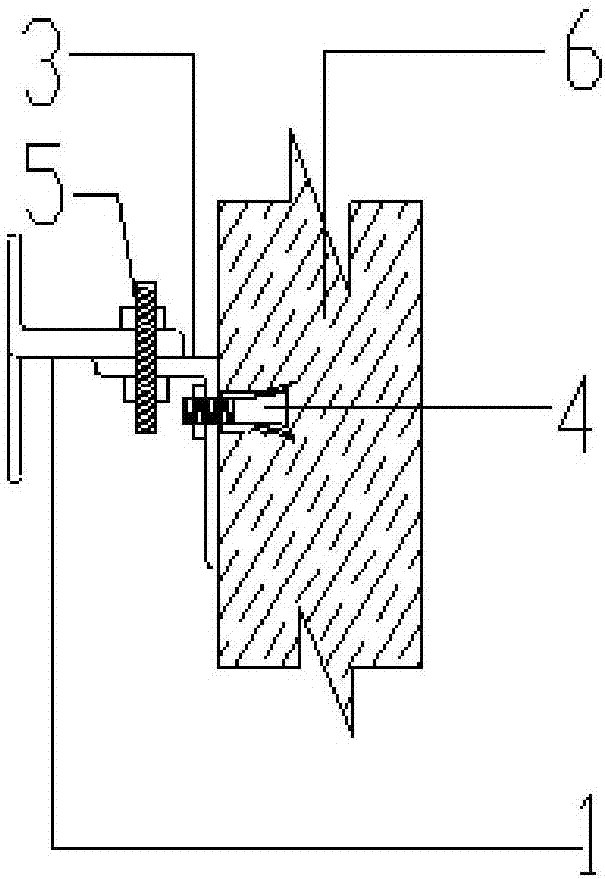

[0022] Such as Figure 1-Figure 4 As shown, a load-sharing decorative brick paste adjustable connector, the beam 3 is made of angle steel, the lower wing of the longitudinally arranged beam 3 is provided with a connecting screw hole 2, and the chemical bolt 4 is connected to the connecting screw hole 2 so that the The beam 3 is effectively connected with the building structure 6. In this embodiment, the building structure 6 is a wall. The upper flange of the beam 3 is provided with a hole for connecting with the connector 1. The connector 1 is processed by 4 thick galvanized flat iron. , The middle part of the tail is cut, and the cut part is bent 90 degrees in two directions to form a T-shaped connecting member. A long screw hole 7 for connecting with the beam 3 is provided at the front of the connecting piece 1 .

[0023] Construction method of the present invention is as follows:

[0024] According to the design requirements, the beam 3 is produced in the processing factor...

Embodiment 2

[0028] The structure and connection relationship of each part of a load-sharing decorative brick laying adjustable connector described in this embodiment are the same as those in Embodiment 1, and the different technical parameters are: the chemical bolt 4 is replaced by a rear embedded part ; The building structure 6 is a component to be decorated.

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap