An artificial reef made of urban construction waste

A technology for urban construction waste and artificial reefs, which is applied in the fields of application, climate change adaptation, fish farming, etc., can solve the problems of undisclosed applications, etc., and achieve the effects of simple structure, waste utilization of existing resources, and low cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

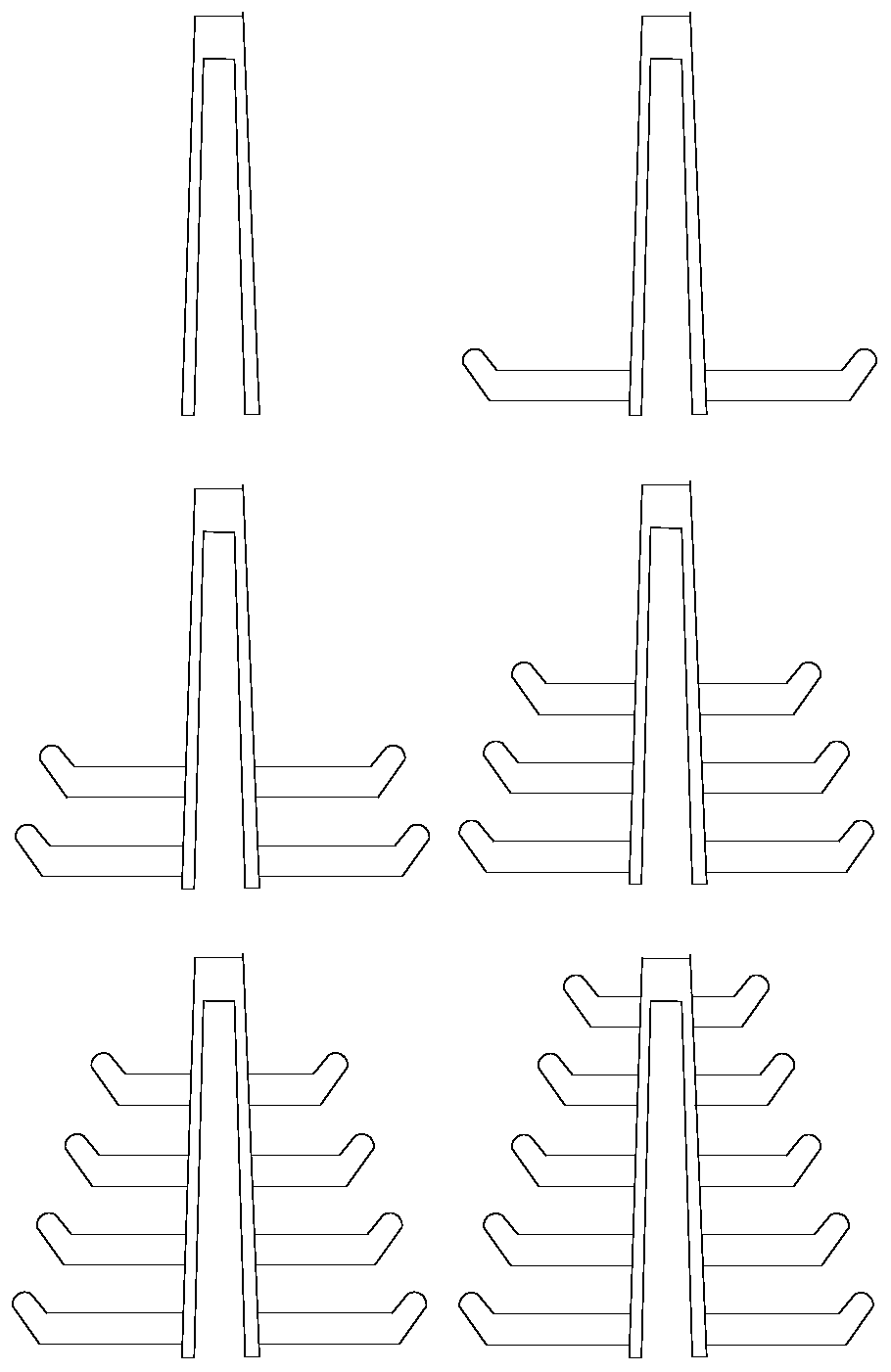

Embodiment 1

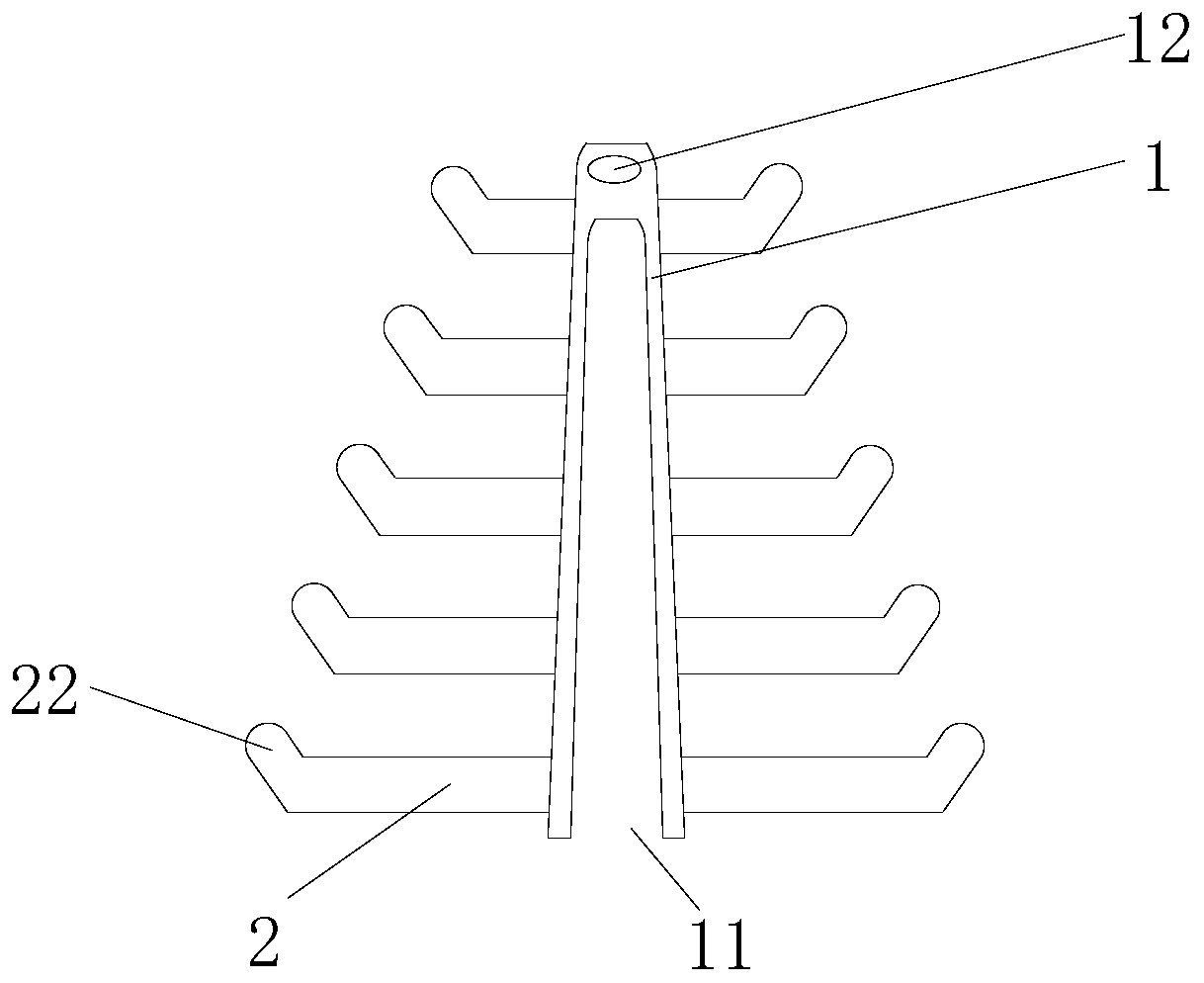

[0033] refer to figure 1 , the artificial reef provided in this embodiment includes concrete pillars 1 and five concrete reefs 2, wherein the cross-sectional size gradually increases from the top to the bottom of the concrete pillars 1, and the center of each concrete reef 2 There are socket holes 21 arranged in cooperation with the concrete pillars 1, and the concrete reefs 2 are sequentially arranged at intervals and socketed on the concrete pillars 1 through the respective socket holes 21; along the concrete The diameters of the concrete reefs 2 in the direction from the top to the bottom of the pillar 1 increase sequentially; each concrete reef 2 is provided with an edge portion 22 bent outward and upward; the concrete pillar 1 is a hollow rod, And the bottom end of the concrete pillar 1 is provided with an insertion opening 11, and the cross-sectional dimension of the insertion opening 11 is larger than the cross-sectional dimension of the top end of the concrete pillar 1...

Embodiment 2

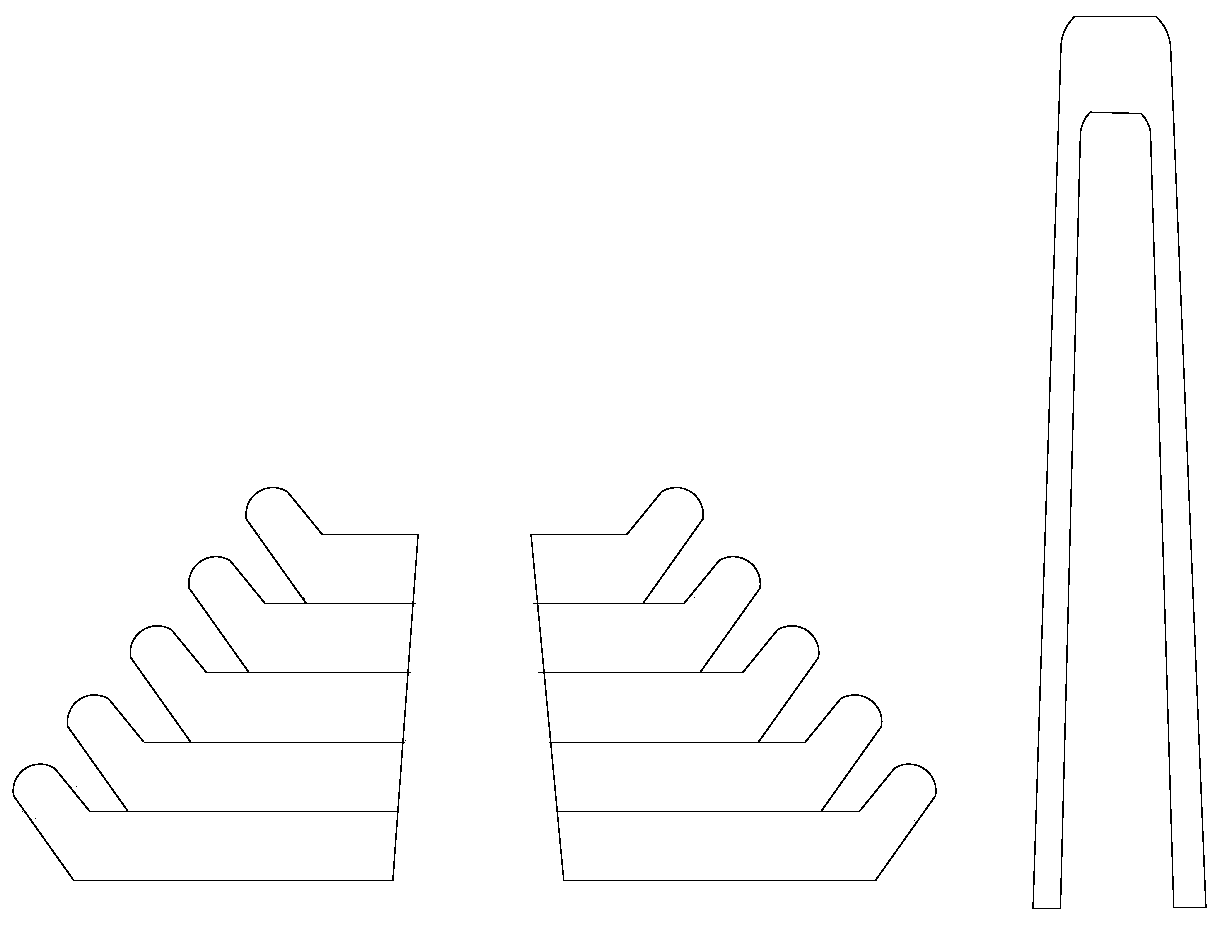

[0038] like Figure 5-7 As shown, compared with the artificial reef provided in the present embodiment 1, the artificial reef provided in the present embodiment is different in that: the end of the concrete reef plate 2 near the socket hole 21 is provided with an installation groove 23, the The installation groove 23 communicates with the sleeve hole 21 and is set through the bottom of the concrete reef 2; the concrete pillar 1 is provided with an installation hole 13 corresponding to each of the concrete reef 2, and the artificial reef It also includes a fixing rod 3 that is threadedly connected with the installation hole 13 and matched with the sleeve hole 21 .

[0039]Both the concrete pillar and the artificial reef are made of recycled foamed concrete, and the mold is made of glass fiber, which makes the present invention high in strength, low in cost, and saves resources by utilizing waste; Seawater erosion experiments enable the present invention to be used normally in ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com