Production equipment and production method of interesting bead product

A technology for production equipment and interesting beads, which is applied in the coating of food, dairy products, milk preparations, etc., can solve the problems of increased process, high labor intensity of personnel, cumbersome production process, etc., to achieve strong chewing and blasting feeling, Rich blasting taste, good blasting effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

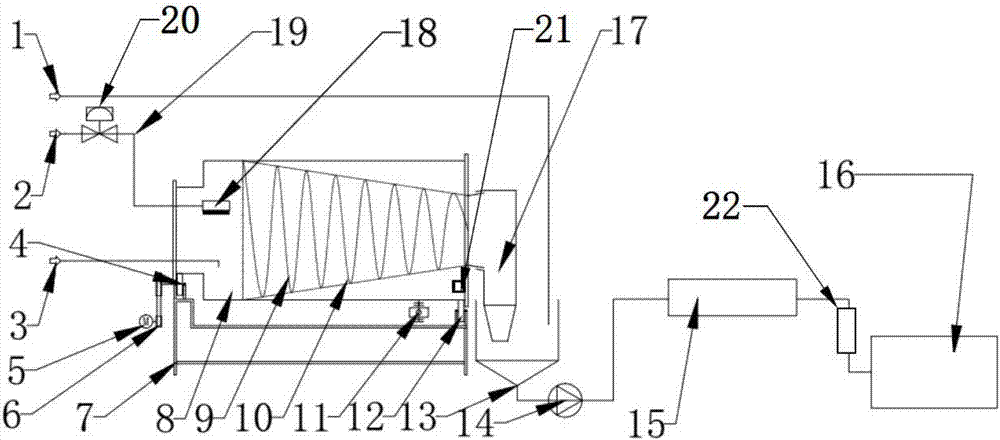

[0057] The present embodiment provides a kind of production equipment of interesting pearl product, as figure 1 As shown, the equipment includes: protection liquid delivery pipeline 1, content combination material solution delivery pipeline 2, coating combination material solution delivery pipeline 3, first rolling support bearing 4, drive motor 5, drive deceleration device 6, support frame 7 , rolling casting forming barrel 8, guiding spiral track 9, conical sieve barrel 10, discharge valve 11, second rolling support bearing 12, mixing barrel 13, feeding pump 14, tubular ultra-high temperature sterilizer 15, filling machine 16, Bead collector 17, pouring distributor 18, control valve 19, time relay 20, liquid level detector 21, plate heat exchanger 22 and power pump;

[0058] Wherein, the rolling casting barrel 8 is a cylinder arranged horizontally, which is fixed on the support frame 7, and one end surface of the rolling casting barrel 8 is provided with a composition liquid...

Embodiment 2

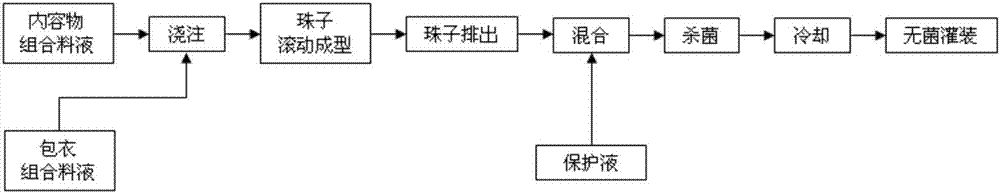

[0068] The present embodiment provides a kind of production method of interesting pearl product, and it is the method that adopts the production equipment of interesting pearl product that embodiment 1 provides to carry out interesting pearl product, such as figure 2 As shown, the method includes the following steps:

[0069] Make the coating combination feed liquid enter the rolling casting molding barrel 8 through the coating composition feed liquid delivery pipeline 3, and reach a certain liquid level;

[0070] Make the content composition material liquid enter the pouring distributor 18 through the content composition material liquid delivery pipeline 2, and form the coating from the pouring distributor 18 and drip into the roll casting molding barrel 8 In the combined material liquid, the crude product of beads is formed; at the same time, the rolling casting molding barrel 8 is made Rolling in the axial direction, the rotational speed of the rolling casting forming bar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com