Shoe piece circulation adhesive drying device

A technology of baking glue and equipment, which is applied in the direction of bonding shoe parts, footwear, and shoe-making machinery, etc., can solve the problems of low drying efficiency, time-consuming and labor-intensive, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

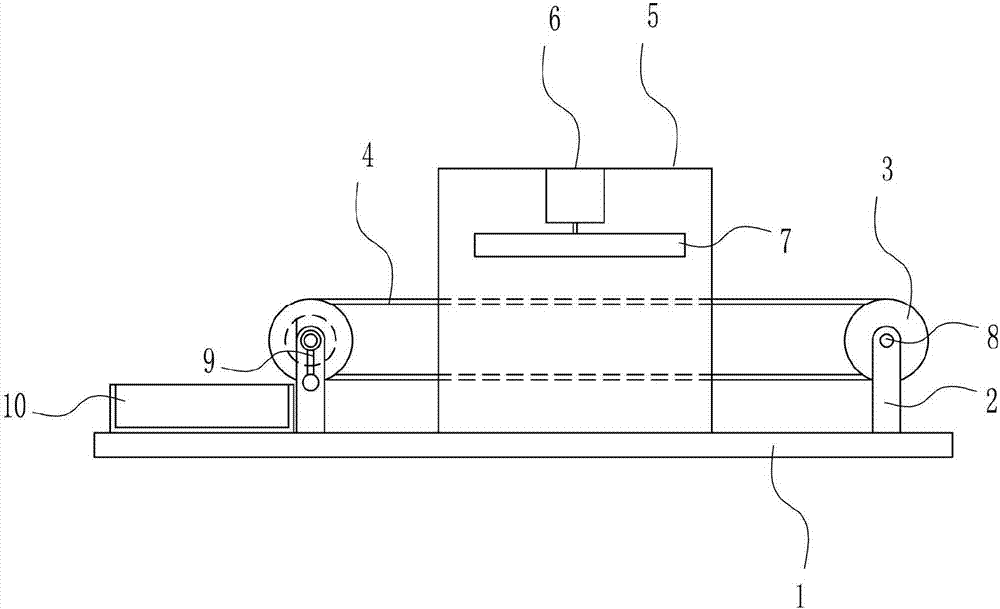

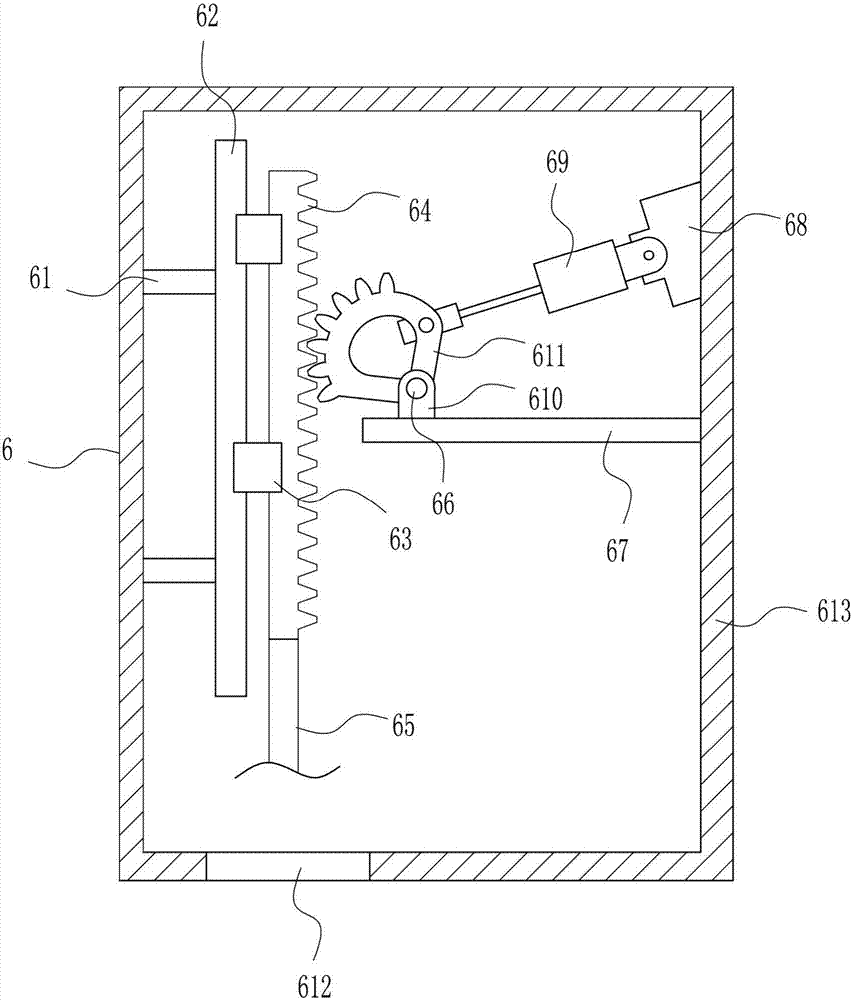

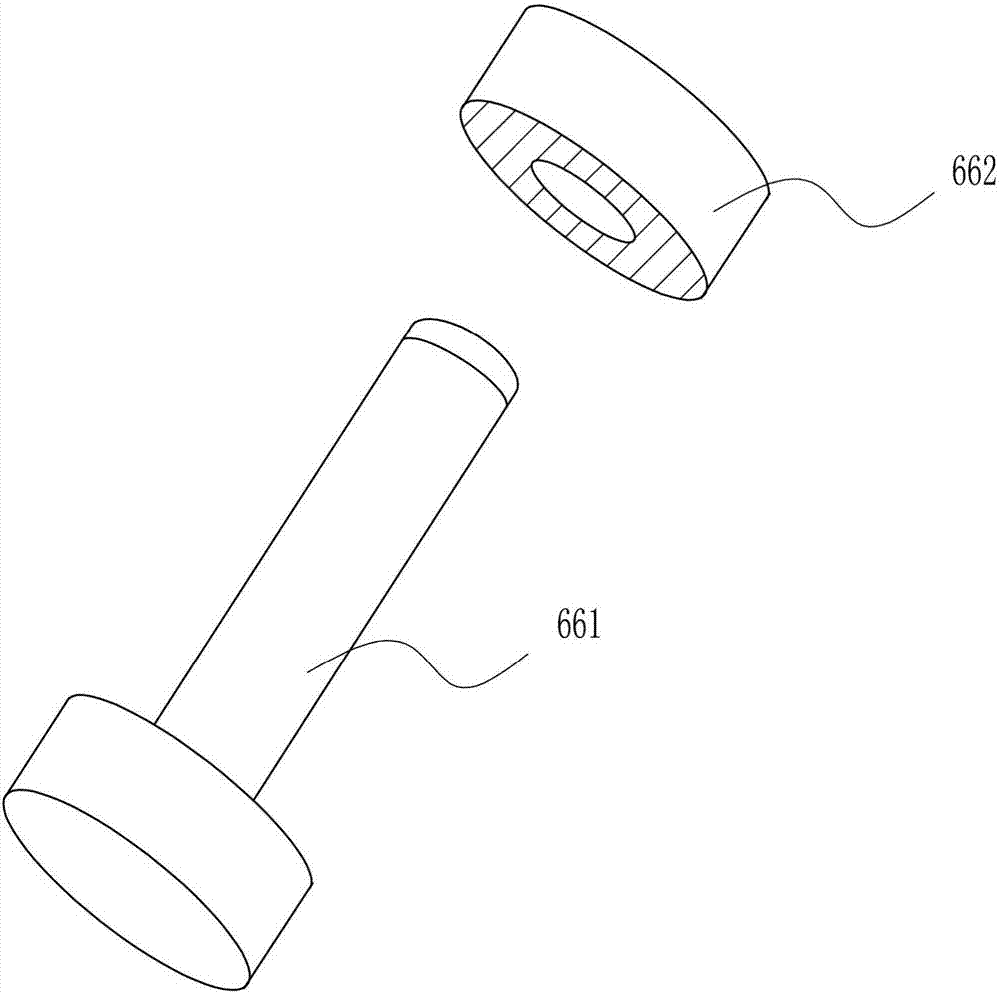

[0034] A kind of shoe parts circulating glue drying equipment, such as Figure 1-6 As shown, it includes a bottom plate 1, a bearing seat 2, a roller 3, a conveyor belt 4, a drying box 5, a lifting device 6, a drying device 7, a first rotating shaft 8, a rocker 9 and a collection frame 10. Bearing seats 2 are welded on both sides, the bearings in the two bearing seats 2 are connected with a first rotating shaft 8 by an interference connection, and a roller 3 is connected on the first rotating shaft 8 by an interference connection. There is a conveyor belt 4 around, a drying box 5 is welded in the middle of the top of the bottom plate 1, the drying box 5 is between the two bearing seats 2, the conveyor belt 4 passes through the drying box 5, and a lifting device is welded in the middle of the top of the drying box 5. 6. A drying device 7 is welded at the bottom of the lifting device 6. The drying device 7 is above the conveyor belt 4. A collection frame 10 is placed on the left...

Embodiment 2

[0036] A kind of shoe parts circulating glue drying equipment, such as Figure 1-6 As shown, it includes a bottom plate 1, a bearing seat 2, a roller 3, a conveyor belt 4, a drying box 5, a lifting device 6, a drying device 7, a first rotating shaft 8, a rocker 9 and a collection frame 10. Bearing seats 2 are welded on both sides, the bearings in the two bearing seats 2 are connected with a first rotating shaft 8 by an interference connection, and a roller 3 is connected on the first rotating shaft 8 by an interference connection. There is a conveyor belt 4 around, a drying box 5 is welded in the middle of the top of the bottom plate 1, the drying box 5 is between the two bearing seats 2, the conveyor belt 4 passes through the drying box 5, and a lifting device is welded in the middle of the top of the drying box 5. 6. A drying device 7 is welded at the bottom of the lifting device 6. The drying device 7 is above the conveyor belt 4. A collection frame 10 is placed on the left...

Embodiment 3

[0039] A kind of shoe parts circulating glue drying equipment, such as Figure 1-6 As shown, it includes a bottom plate 1, a bearing seat 2, a roller 3, a conveyor belt 4, a drying box 5, a lifting device 6, a drying device 7, a first rotating shaft 8, a rocker 9 and a collection frame 10. Bearing seats 2 are welded on both sides, the bearings in the two bearing seats 2 are connected with a first rotating shaft 8 by an interference connection, and a roller 3 is connected on the first rotating shaft 8 by an interference connection. There is a conveyor belt 4 around, a drying box 5 is welded in the middle of the top of the bottom plate 1, the drying box 5 is between the two bearing seats 2, the conveyor belt 4 passes through the drying box 5, and a lifting device is welded in the middle of the top of the drying box 5. 6. A drying device 7 is welded at the bottom of the lifting device 6. The drying device 7 is above the conveyor belt 4. A collection frame 10 is placed on the left...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com