Multi-sliding-block variable-tonnage continuous forging and pressing machine tool

A forging machine tool and multi-slider technology, which is applied to forging presses, forging presses, forging press drive devices, etc., can solve the problems of backward production mode, fixed tonnage, waste of production time, etc., and achieve short distance between stations. Large forging area, overcome time-consuming and labor-intensive effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

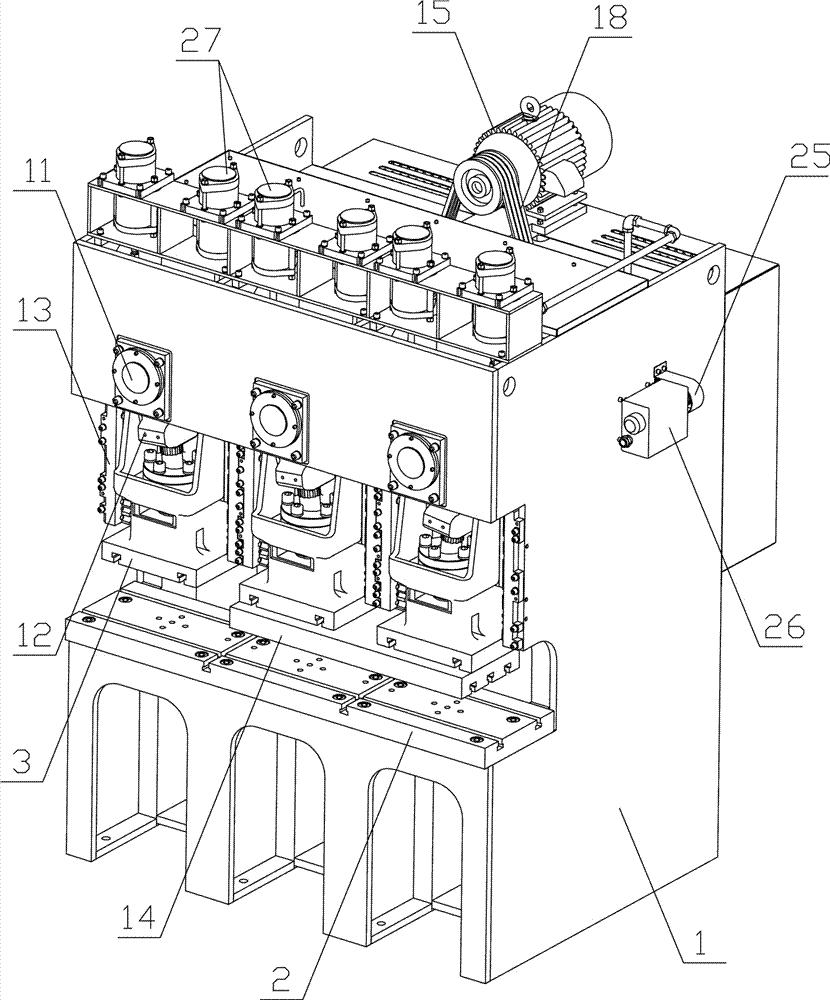

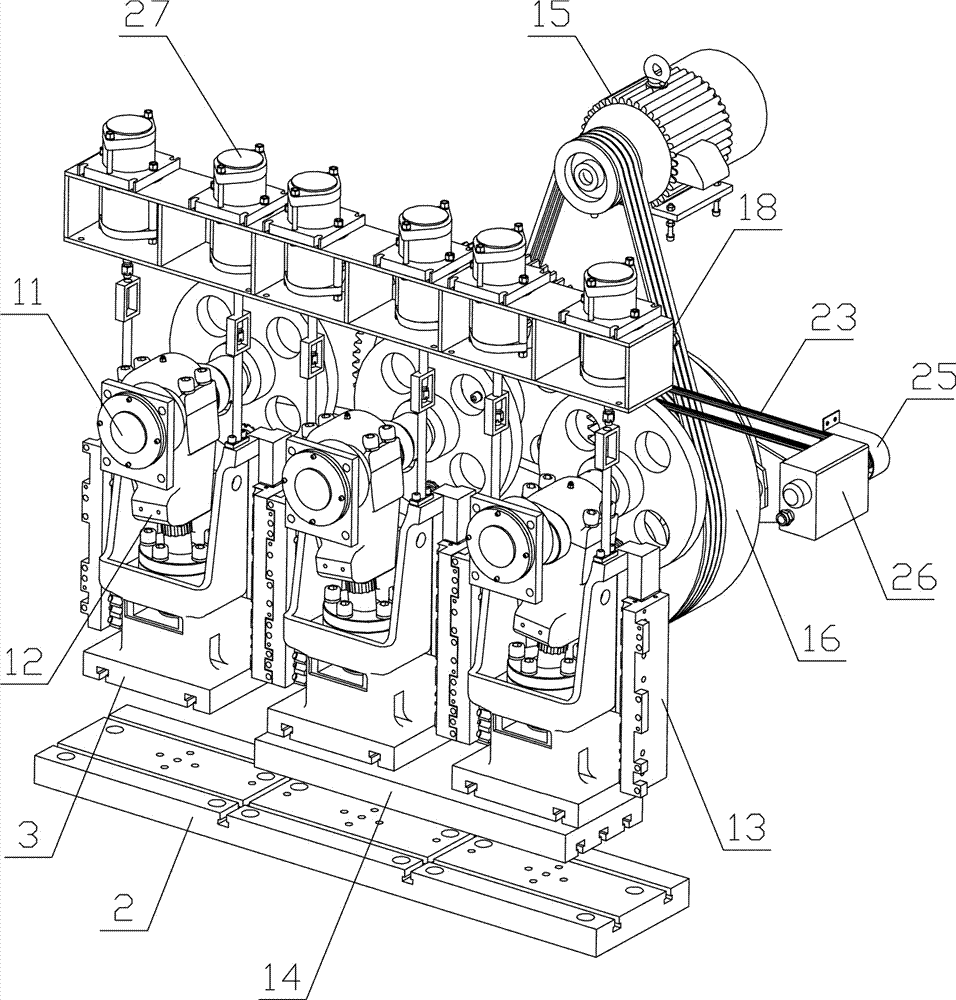

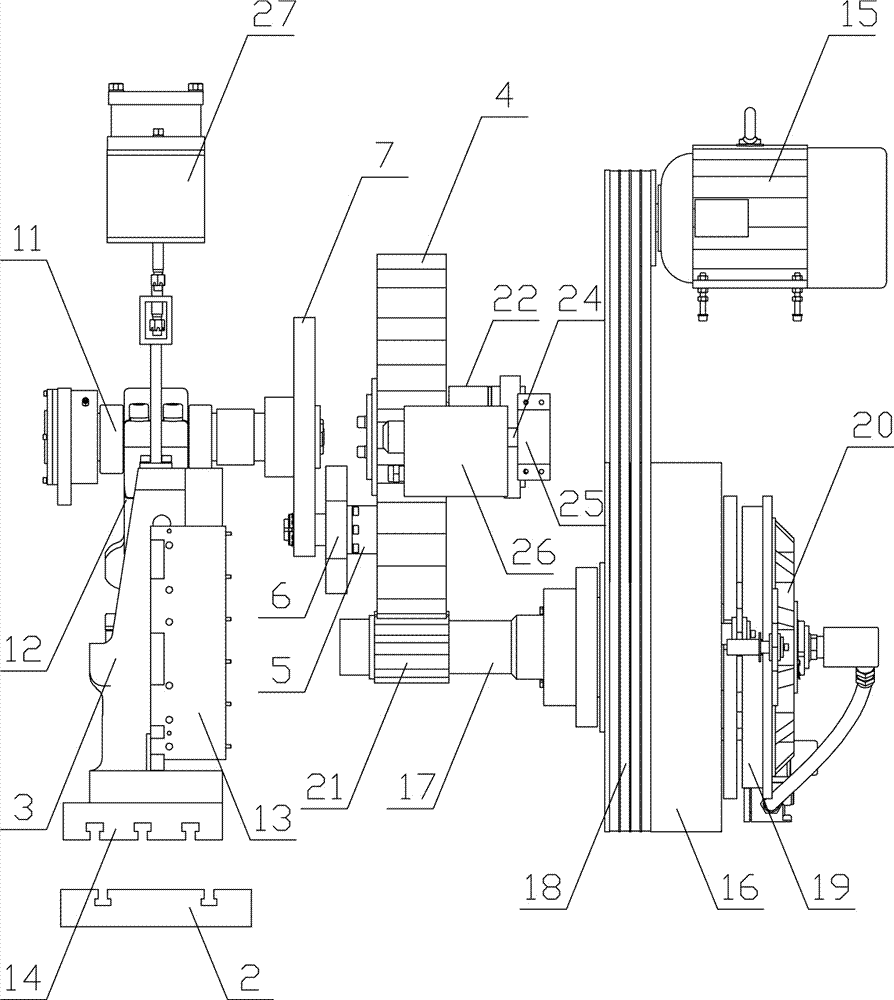

[0021] see Figure 1-4 , a multi-slider variable tonnage continuous forging machine tool, with a frame 1, a forging mechanism and a forging platform 2 are arranged on the frame 1; the forging mechanism includes a driving mechanism, a connecting rod transmission mechanism, and three sets arranged side by side The crank-link mechanism and the slide block 3 connecting each set of crank-link mechanism; the drive mechanism has a drive gear 4, and an eccentric shaft 5 is arranged on the drive gear 4; the link transmission mechanism consists of a transmission link 6 Composed of three transmission wheels 7, the transmission connecting rod 6 is a shuttle-shaped structure, and the middle and two ends of the transmission connecting rod 6 are respectively provided with mounting holes 8, and the transmission wheel 7 is provided with an eccentric hole 10, and the two ends of the transmission connecting rod 6 The mounting holes are respectively connected to the eccentric holes on the two tra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com