New technolgy and device for poly acrylonitril fiber preoxidation and carbonation

A polyacrylonitrile fiber, pre-oxidation technology, applied in the chemical characteristics of fibers, textiles and papermaking, etc., can solve the problems of low thermal efficiency and slow adjustment speed of electric furnaces

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

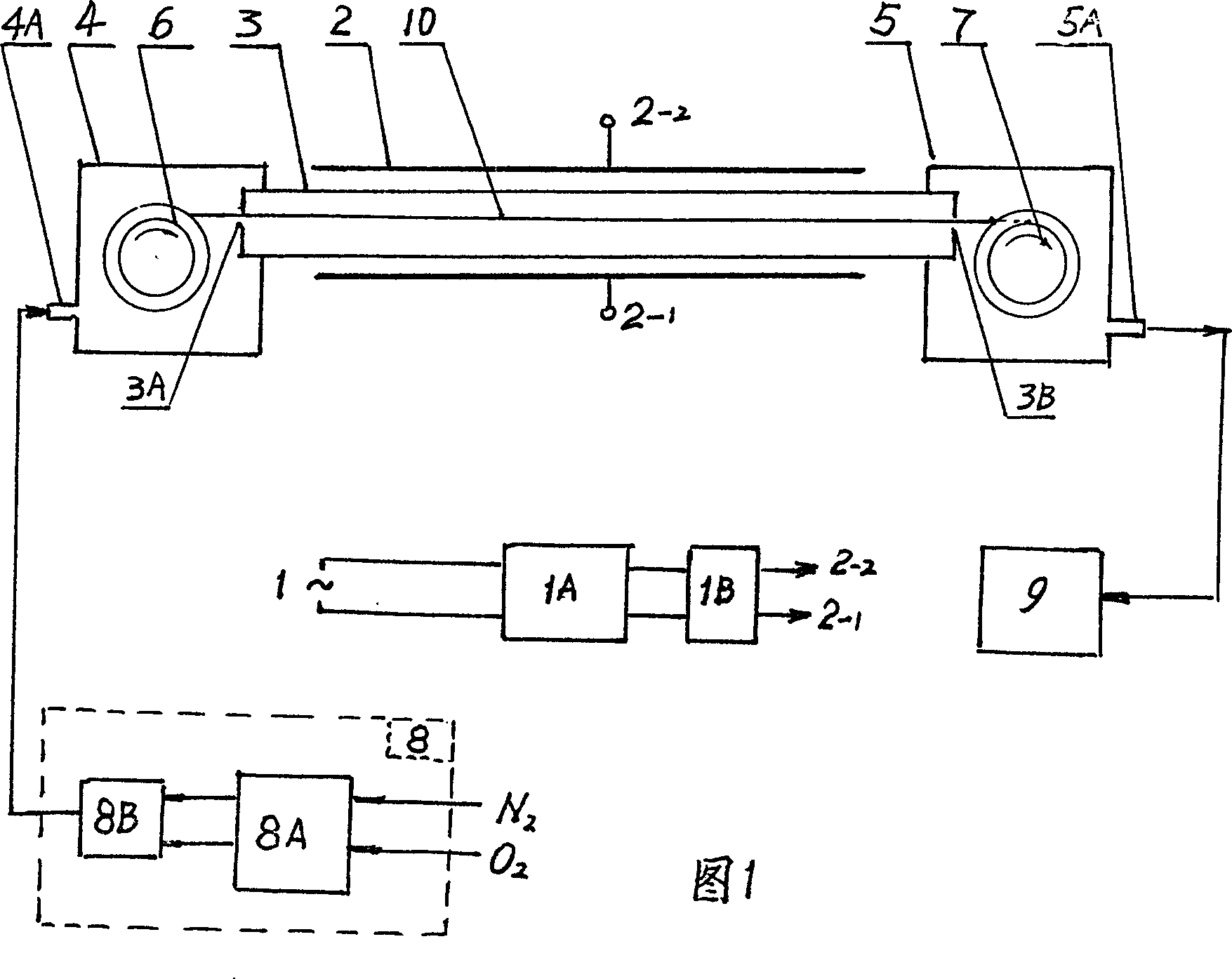

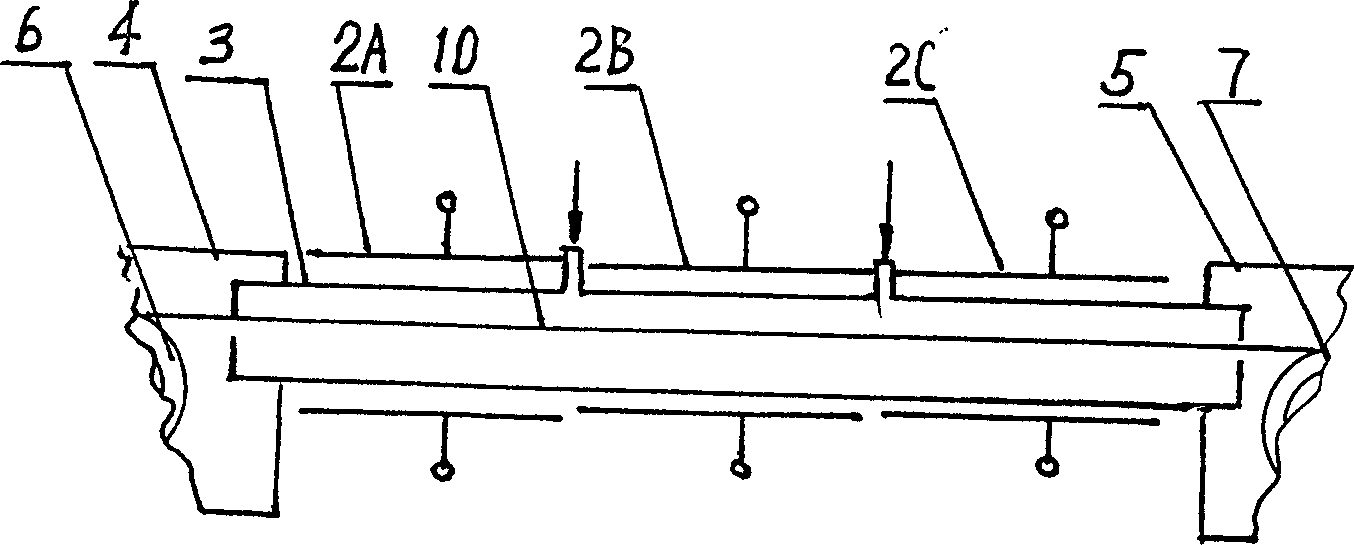

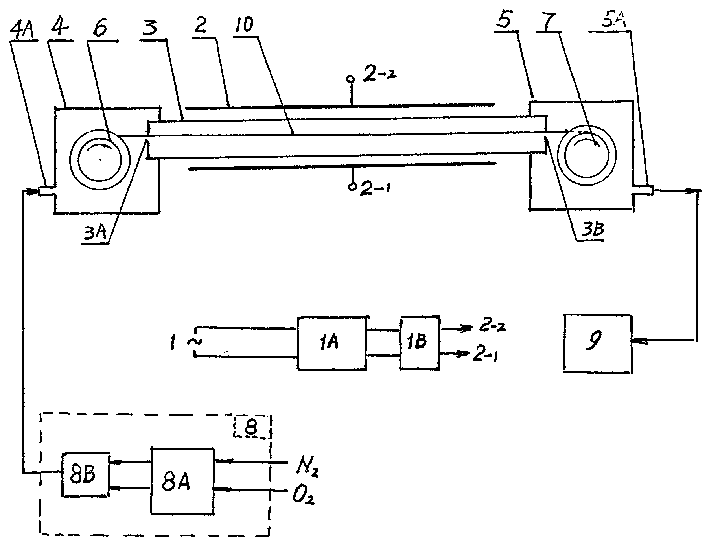

[0009] In order to achieve the purpose of the present invention and to improve the existing carbon fiber processing technology, a negative pressure plasma heating device with a high-frequency power supply 1 as an energy source is specially designed. The plasma reaction chamber 3 in the device is a flat hollow made of quartz glass. The cavity has wire inlets and outlets (3A, 3B) on both ends, and front and rear sealing covers (4, 5) are arranged. Its function is to keep the main structural components of the differential wire take-up mechanism, the front wire take-up wheel 6 and the wire take-up wheel 7 in a sealed state to form a negative pressure environment in the reaction chamber. Correspondingly arranged outside the upper and lower planes of the reaction chamber 3 are parallel plate excitation electrodes 2 corresponding to their size and shape. After the high-frequency power supply is connected, a high-frequency alternating uniformity is formed in the quartz reaction chamber be...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com