Special lathe support table for wheel processing

A technology for special lathes and support tables, applied in metal processing equipment, metal processing machinery parts, supports, etc., can solve the problems of difficult clamping of hubs and large clamping size range, and achieve easy maintenance, large clamping size range, The effect of improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

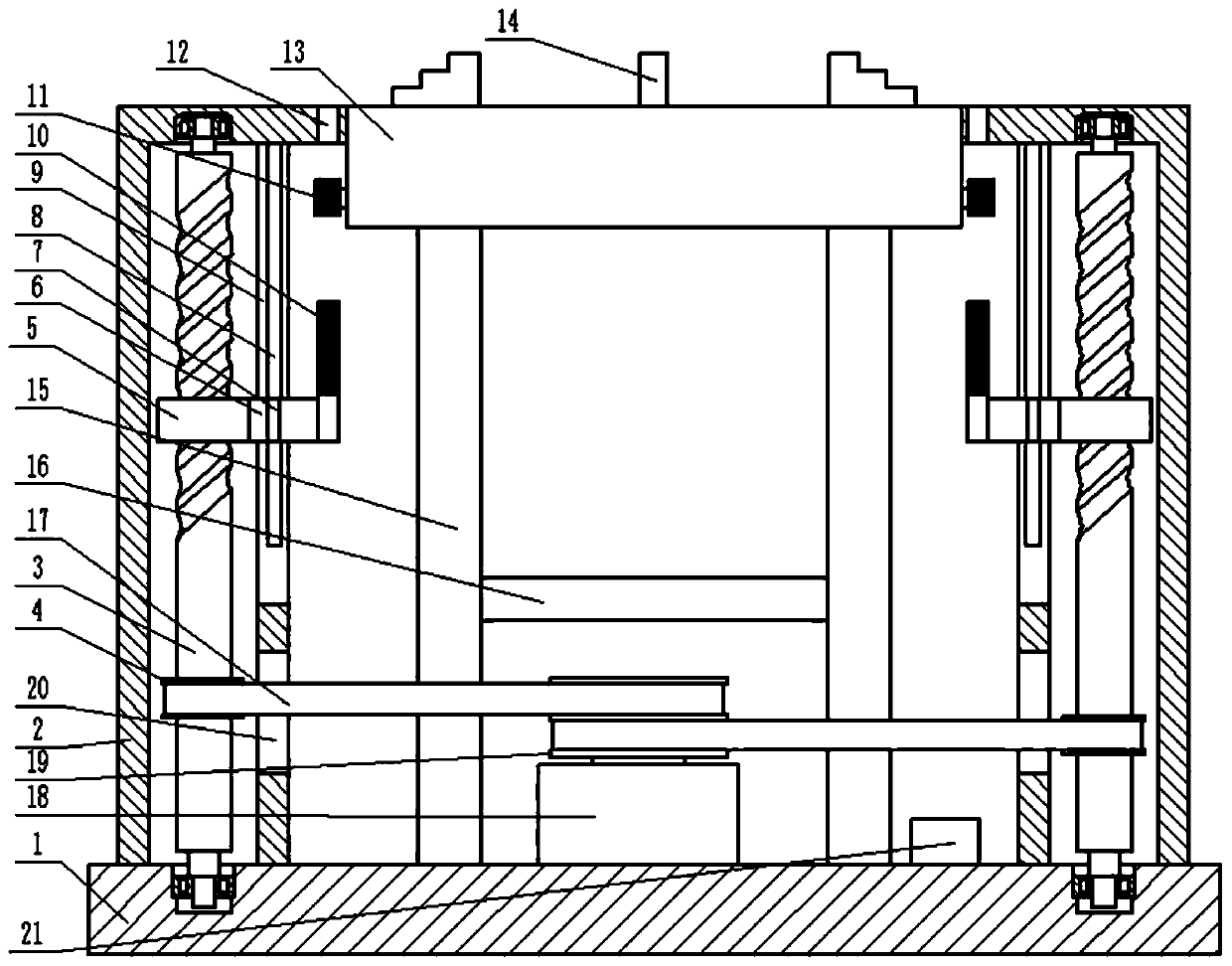

[0018] Such as figure 1 As shown, the special lathe support table for wheel hub processing includes a base 1, and the two sides of the base 1 are provided with a hollow vertical rod 2 symmetrical to the center line of the base 1. It is characterized in that a rotating rod 3 is arranged inside the vertical rod 2, and the The upper end and the lower end of the rotating rod 3 are respectively connected with the top plate and the base 1 of the vertical rod 2 through bearings, the lower part of the rotating rod 3 is provided with a first synchronous pulley 4, the upper part of the rotating rod 3 is provided with threads, and the rotating rod 3 with the threaded part is provided with There is a nut 5 matched with the thread, on which a connecting piece 6 facing the center line of the base 1 is arranged, and a chute 8 which is slidably matched with the sliding block 7 on the connecting piece 6 is arranged in the upper slot 9 . The connecting piece 6 extends toward the centerline of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com