Electric screwing machine with easily controllable tightness

A high-level, electric technology, applied in the field of electric screwing machines, can solve the problem of difficulty in controlling the degree of tightening at the connection of steel bars, and achieve the effect of easy tightening, control of tightening, and damage prevention.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

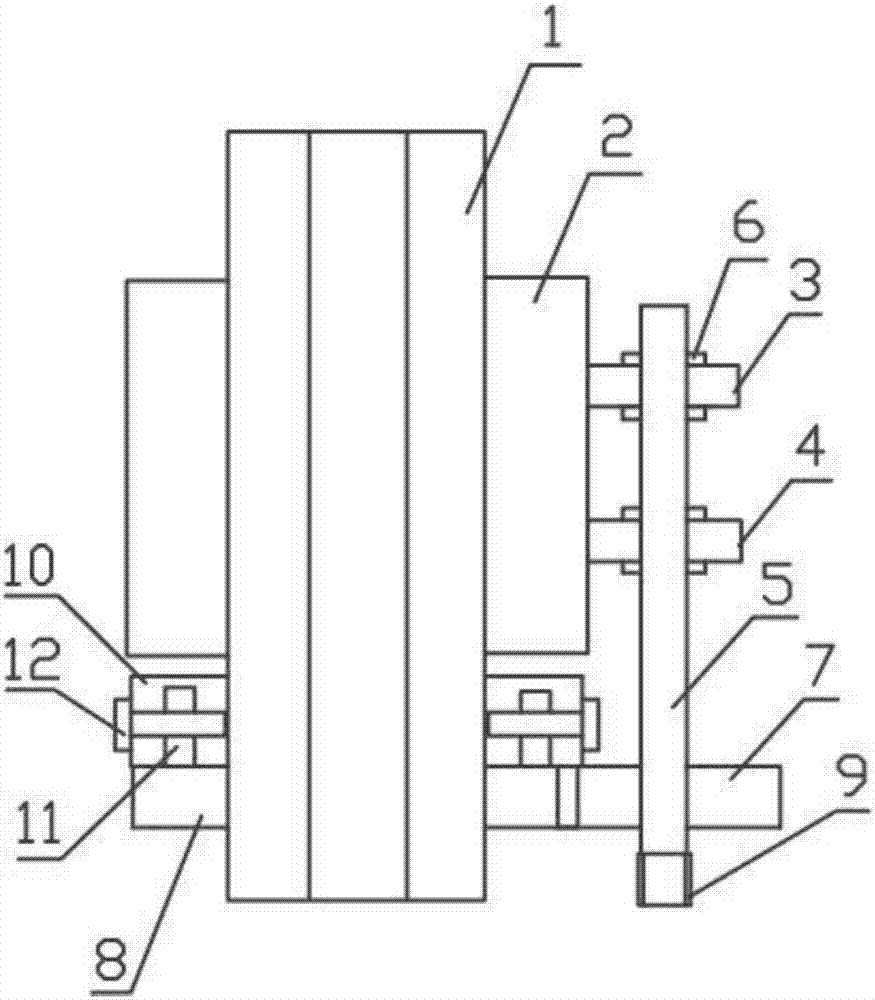

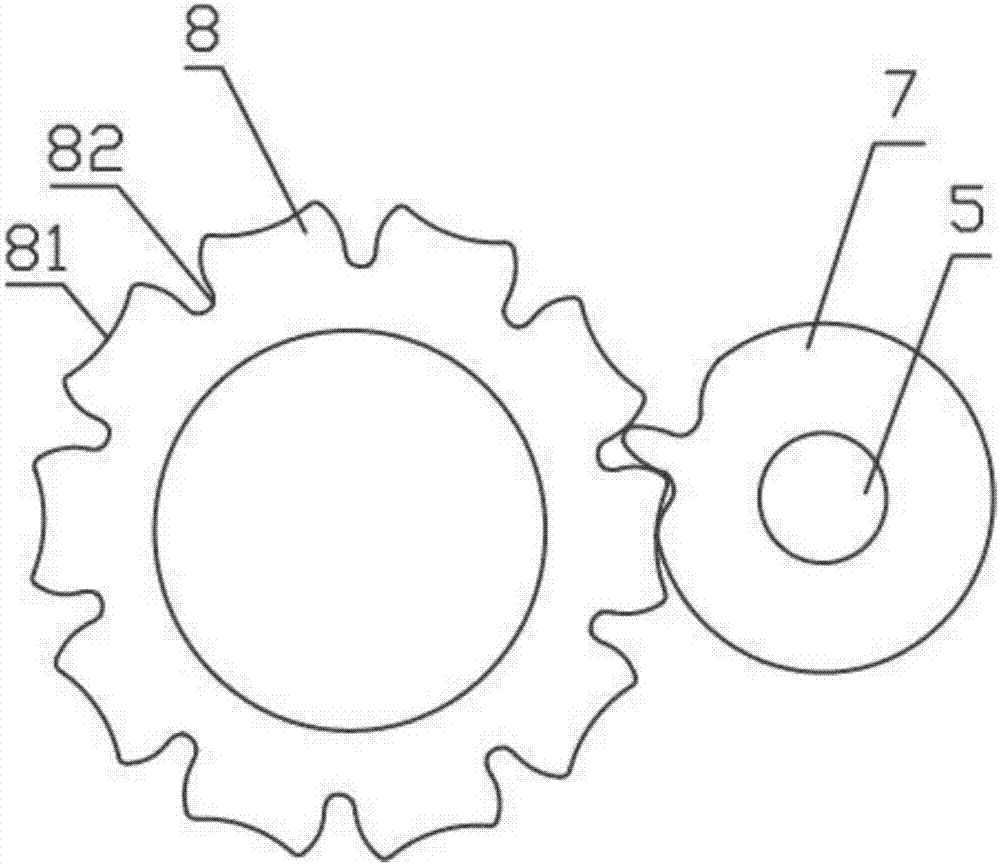

[0027] Such as figure 1 As shown, the present invention is an electric threading machine that is easy to control the degree of tightening, including a quick-opening and closing clamp 1 and a quick-opening and closing fixing sleeve 2. The quick-opening and closing clamp 1 is installed on the quick-opening and closing fixing sleeve 2. A first fixing rod 3 and a second fixing rod 4 are welded on a movable side wall of the quick opening and closing fixing sleeve 2, and the axial directions of the first fixing rod 1 and the second fixing rod 2 are both perpendicular to the quick opening and closing fixing sleeve The axis of 2 is vertical. It also includes a rotating shaft 5, the rotating shaft 5 is fixed on the first fixed rod 3 and the second fixed rod 4 through a bearing seat 6, and the axial direction of the rotating shaft 5 is parallel to the axial direction of the quick opening and closing clamp 1. A driving wheel 7 is provided on the rotating shaft 5, and the periphery of the ...

Embodiment 2

[0029] Further improved on the basis of embodiment 1, the present invention provides an electric screwing machine that is easy to control the degree of tightening. The end of the quick opening and clamp 1 is integrated with a stop ring 10, and the driven wheel 8 passes The clearance fit is sleeved on the end of the quick opening and closing jig 1 to abut the limit ring 10; on the driven wheel 8 and on the end surface facing the limit ring 10, two trunnions 11 are protruding, and the trunnions 11 are both provided There is a through hole, the end surface of the limit ring 10 facing the driven wheel (8) is provided with a limit groove adapted to the trunnion 11, and the side wall of the limit ring 10 is provided with a threaded hole. The trunnion 11 is inserted into the limit groove, and the bolt 12 is screwed into the threaded hole and the through hole on the trunnion 11 to fix the driven wheel 8 on the limit ring 10 in turn.

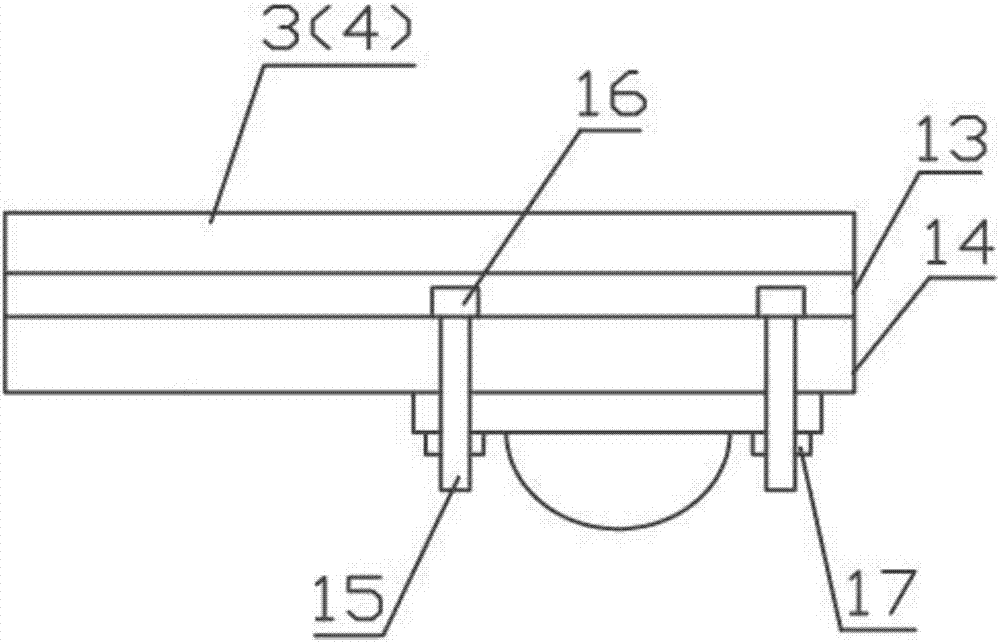

[0030] The side walls of the first fixed rod 3 and th...

Embodiment 3

[0032] Further improved on the basis of embodiment 1, the present invention provides an electric screwing machine that is easy to control the degree of tightening, which also includes a rocker 18 that is adapted to the joint 9, and the interface and joint of the rocker 18 9 can be adapted.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com