Steel refining furnace slag ladle translation system and process

A translational system and steel-making furnace technology, applied in the field of steel-making process and metallurgical solid waste, can solve the problems of uneconomical, increased labor capacity in workshops, high investment and maintenance costs of tank trucks, reduce production and transportation costs, realize space Adjust to meet the effect of anterograde transportation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

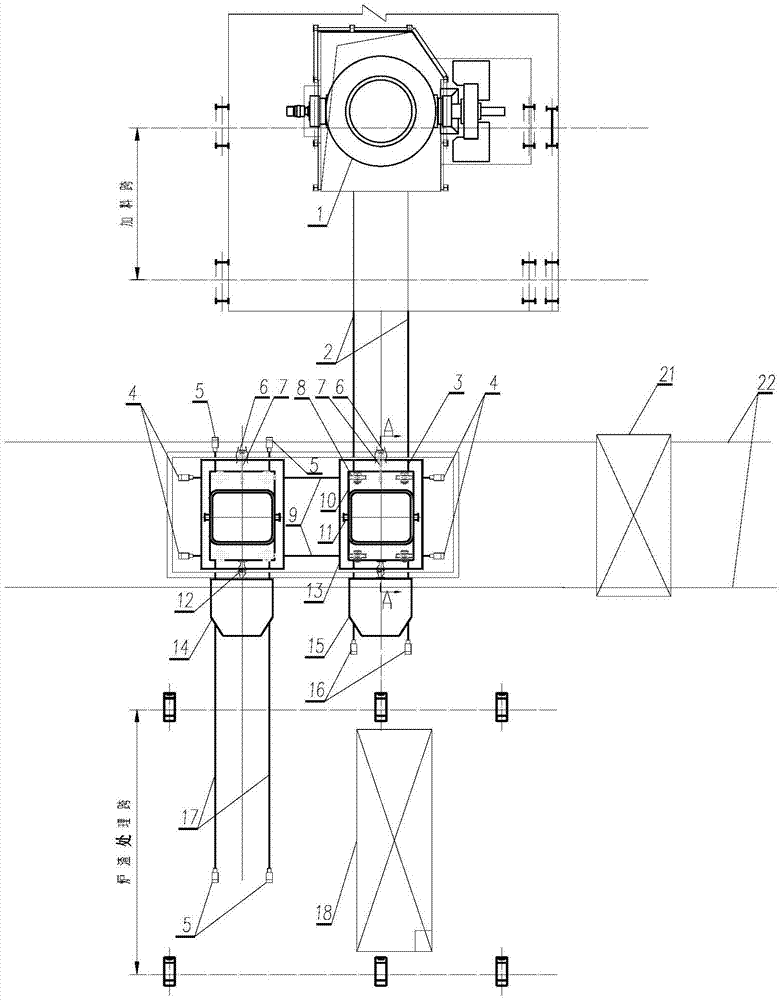

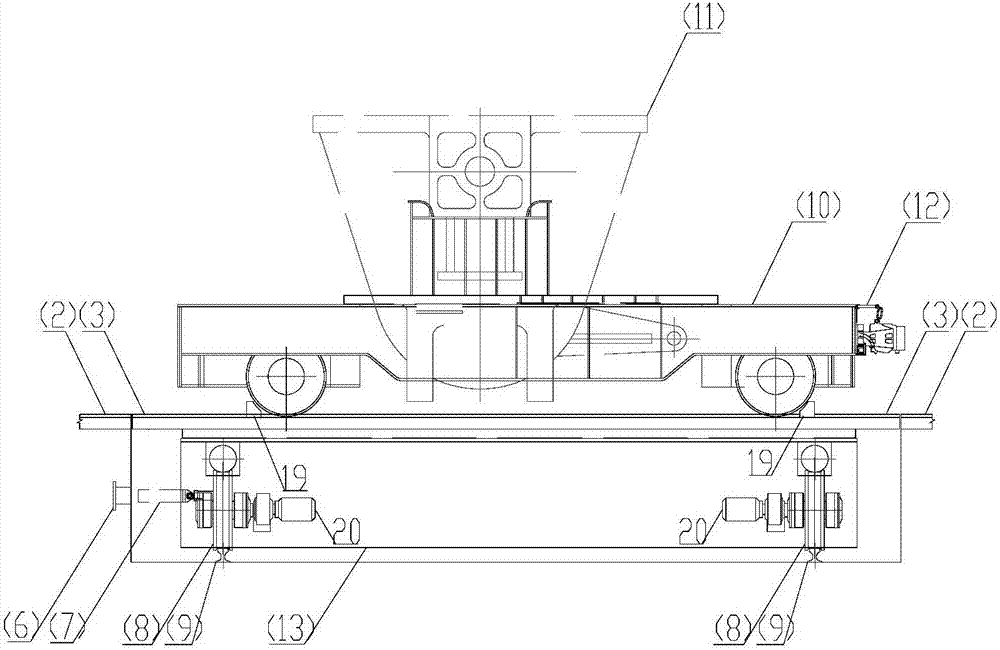

[0033] Such as figure 1 and figure 2 As shown, the present invention is a slag car translation system for steelmaking, 1# ground track 2 and 2# ground track 17 are arranged in parallel on the ground, 1# ground track 2 corresponds to steelmaking furnace 1, and 2# ground track 17 corresponds to slag In the processing area, a translation trolley track 9 is arranged between the 1# ground track 2 and the 2# ground track 17, and the translation trolley track 9 is provided with a translation trolley reciprocating along the track;

[0034] The top of the translation trolley track 9 is provided with a gantry crane for dragging the translation trolley, and the gantry crane includes an elevated track 22 and a crane 21 slidably arranged on the elevated track;

[0035] Two ends of the translation trolley along its moving direction are provided with pull rings matched with the crane.

[0036] The end of the 1# ground rail 2 away from the steelmaking furnace is provided with a 1# ground r...

Embodiment 2

[0039] As a specific solution of Embodiment 1, the end of the translation trolley along its moving direction is provided with a pull ring matching the crane.

Embodiment 3

[0041] As a specific solution of Embodiment 1, the track of the translation trolley is arranged in a storage pit, and a bolt hole 6 for fixing the translation trolley is arranged in the storage pit, and a bolt hole 6 for fixing the translation trolley is provided on the translation trolley. The pin 7 that the hole matches. Specifically, the latch device 7 is a pneumatically driven latch, an electrically driven latch or a hydraulic cylinder driven latch.

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap