Box-shaped steel girder track deicing vehicle

A technology of box-shaped steel beams and deicing vehicles, which is applied in track cleaning, construction, cleaning methods, etc., can solve the problem of ice coating on the box-shaped steel beams of tour bus tracks, and achieve fully automatic deicing process, protection safety, and ease of use. The effect of the operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The embodiments of the present invention will be described in detail below with reference to the accompanying drawings, but the present invention can be implemented in various ways defined and covered by the claims.

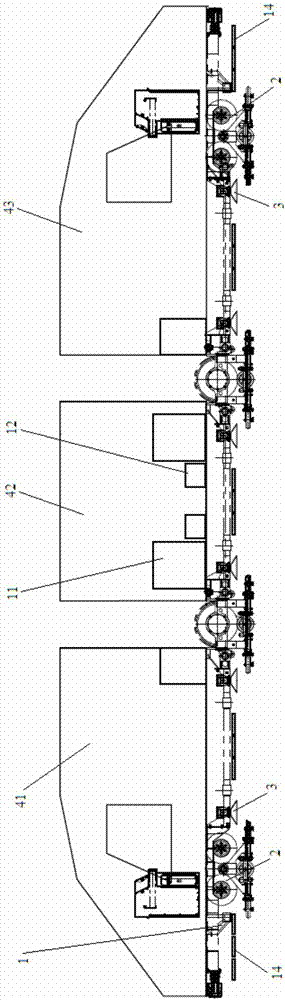

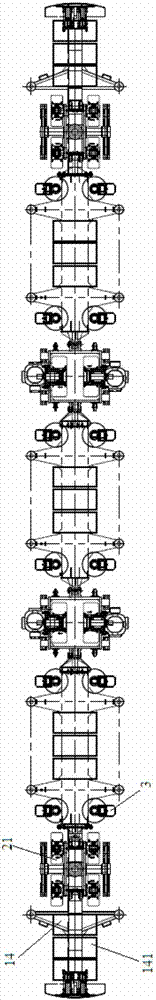

[0032] see Figure 1 to Figure 2 , a kind of box-shaped steel girder track deicing vehicle of the present invention comprises a car body and a deicing mechanism for carrying out deicing and snow removal to box-shaped steel girder tracks; The main structure of the car and the tail car is the same, and the head car can be used as the tail car in the formation of the deicing car; One set is set along the marshalling reverse direction of the deicing vehicle.

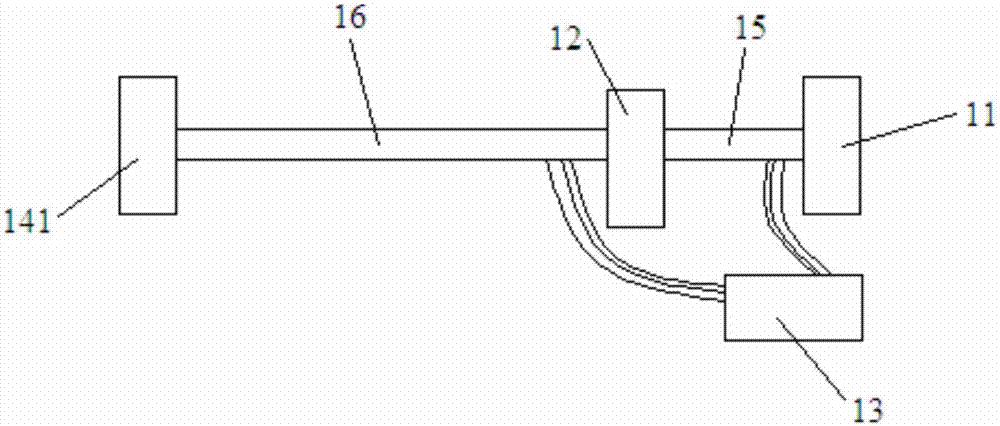

[0033]For the deicing vehicle of the present invention, the deicing and snow mechanism includes two groups of induction melting ice devices, each group of induction melting ice devices includes an induction heating host 11, an induction transformer 12, a water tank 13 and multiple groups of induction he...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com