Sucker rod pulling out and lifting device used for oil field operation

A lifting device and sucker rod technology, which is applied to drill pipes, drilling equipment, earth-moving drilling, etc., can solve the problems of small diameter of sucker rods and high labor intensity of employees, so as to reduce the number of liftings and improve the operation efficiency. , the effect of improving the degree of automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be further described below in conjunction with accompanying drawing:

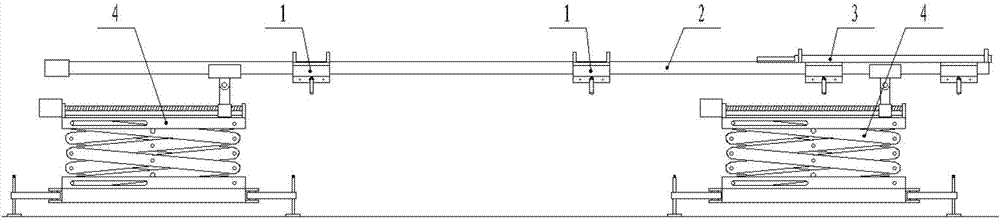

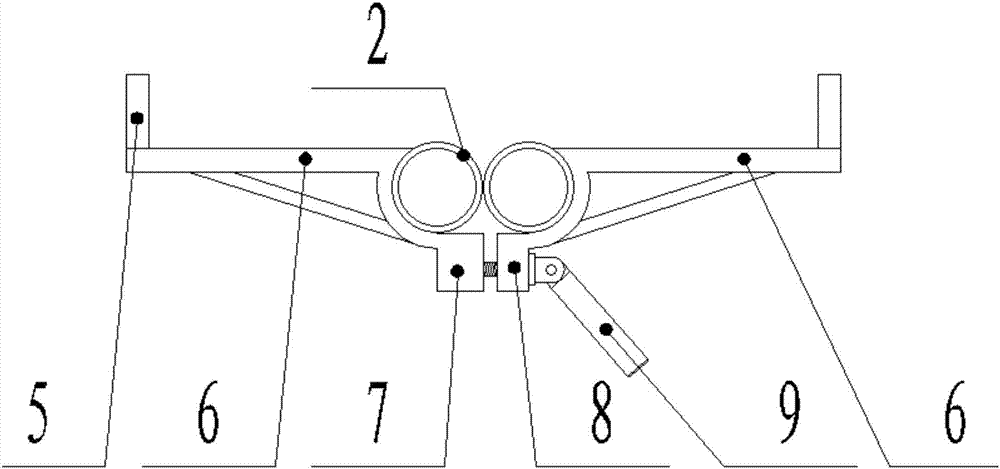

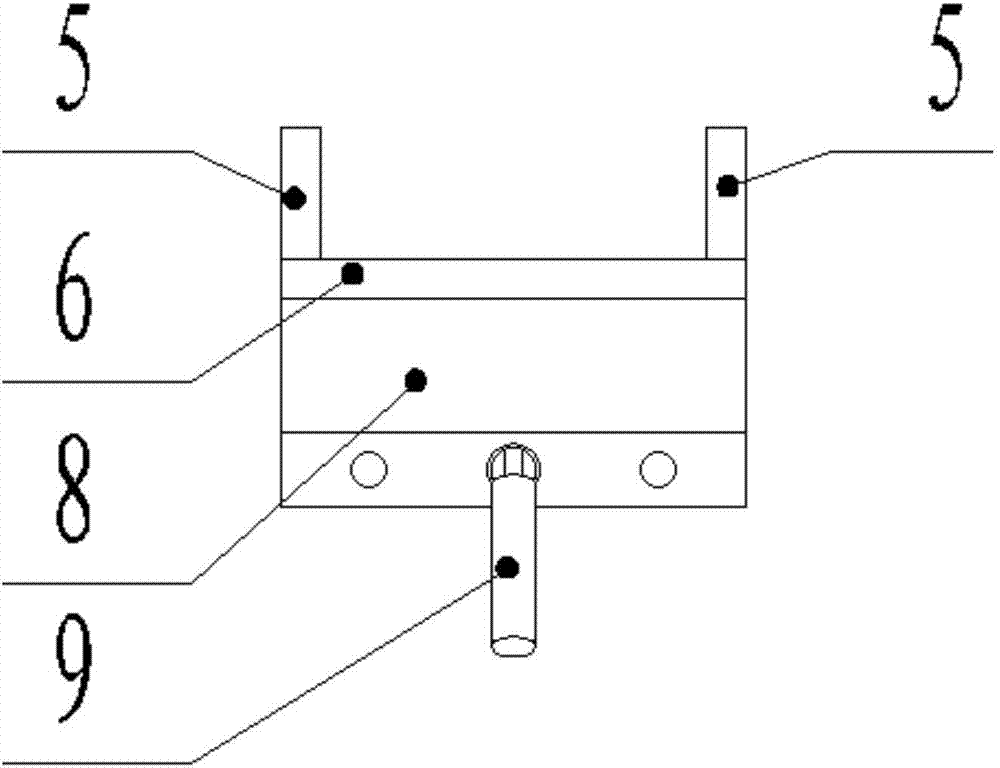

[0021] This embodiment includes a lifting conveying device 4 and a slideway 2, the slideway 2 is fixedly installed on the lifting device 4, and can be lifted and moved and axially moved under the drive of the lifting device 4, the slideway 2 is composed of two The oil pipes are arranged side by side and close together. The above is the basic structure of the automation device used for conveying oil pipes in the prior art, and since it is the prior art, it will not be repeated here.

[0022] The main innovation point of the present invention is that the present invention also includes a front support rod device 1 and a rear support rod device 3 , both of which are fixedly installed on the slideway 2 . When lifting and lowering the sucker rod, multiple sucker rods can be placed on the sucker rod bracket of the present invention at one time (the specific number of sucker rods...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com