Positioning device of ultralarge excavator track pin shaft

A technology for positioning devices and excavators, applied to mechanical equipment, connecting components, etc., can solve the problems of high machining cost, difficult casting process, wear, etc., to avoid falling blocks or parts failure, avoid manufacturing shape and position errors, The effect of reducing casting risk

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be further described below in conjunction with the accompanying drawings. The following examples are only used to illustrate the technical solution of the present invention more clearly, but not to limit the protection scope of the present invention.

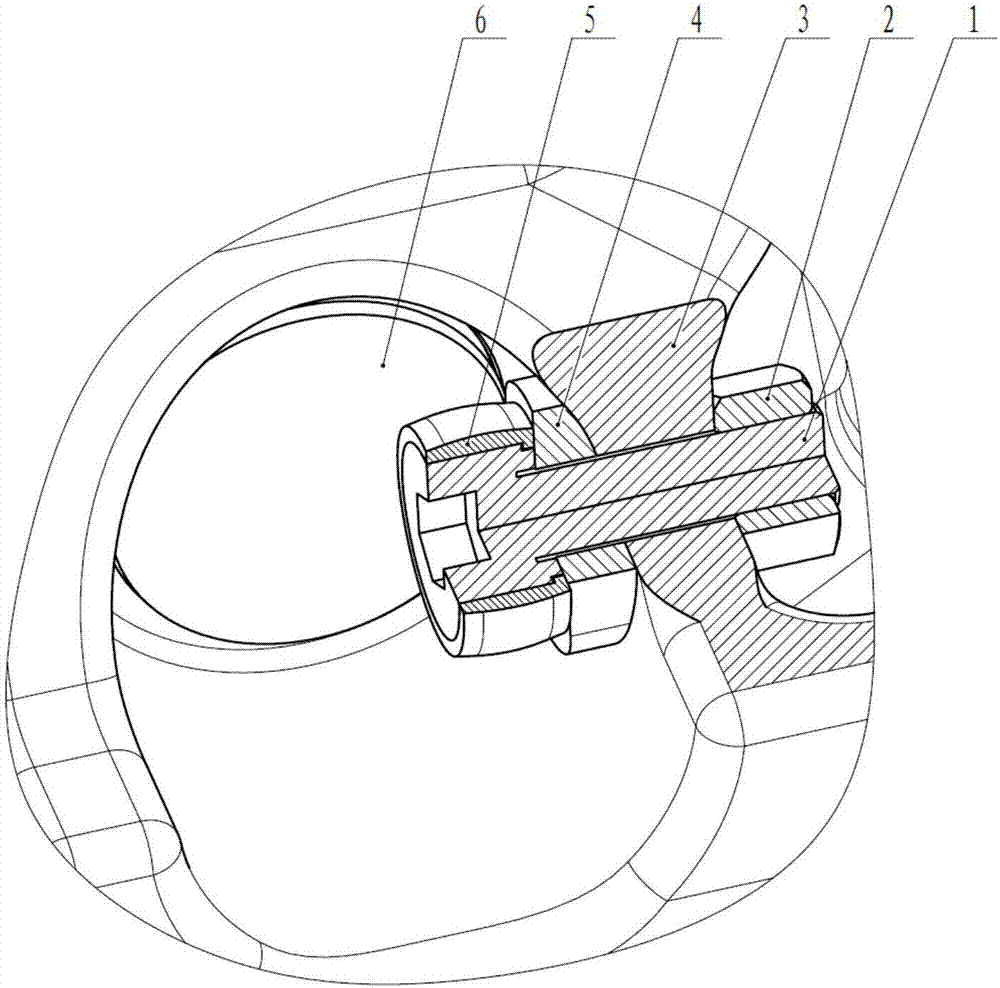

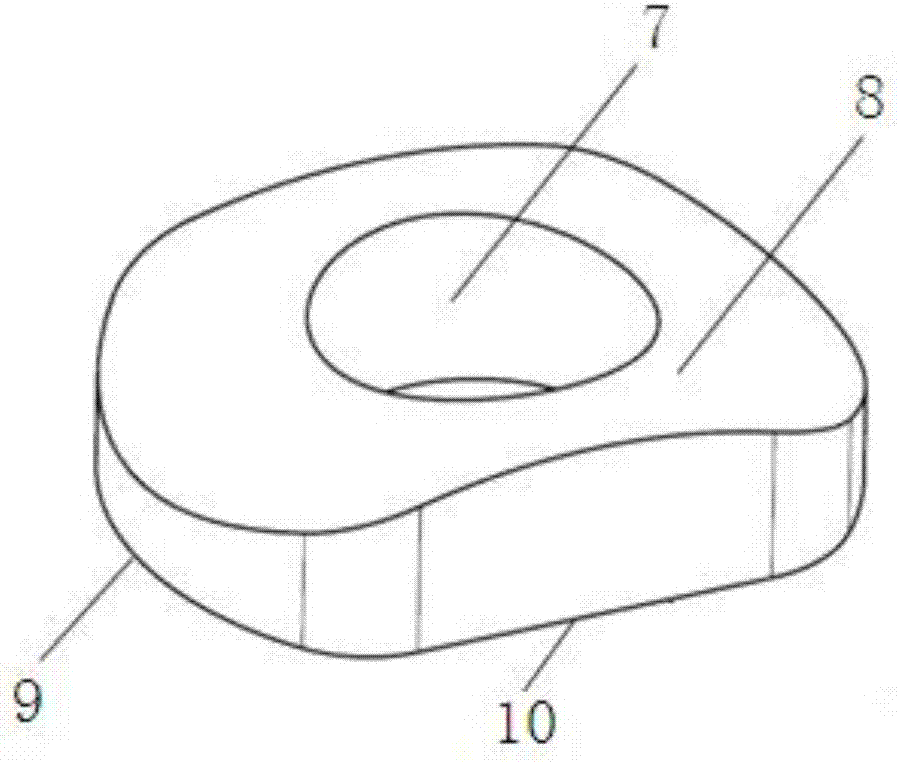

[0021] Such as figure 1 As shown, a positioning device for a super large excavator track pin is characterized in that it includes a track shoe 3, a pin shaft 6, a nut 2, a hexagon socket head cap screw 1, a spacer 4 and a drum sleeve 5. The device is located at the outer end of the pin shaft 6 and installed horizontally. After the two track shoes 3 are put together, use the pin shaft 6 to pass through the pin holes sequentially from the outside to the inside. Spacer 4, adjust the arc surface of the spacer 4 to match the arc surface of the track shoe 3 and tighten the nut 2, so as to realize the axial positioning of the pin shaft.

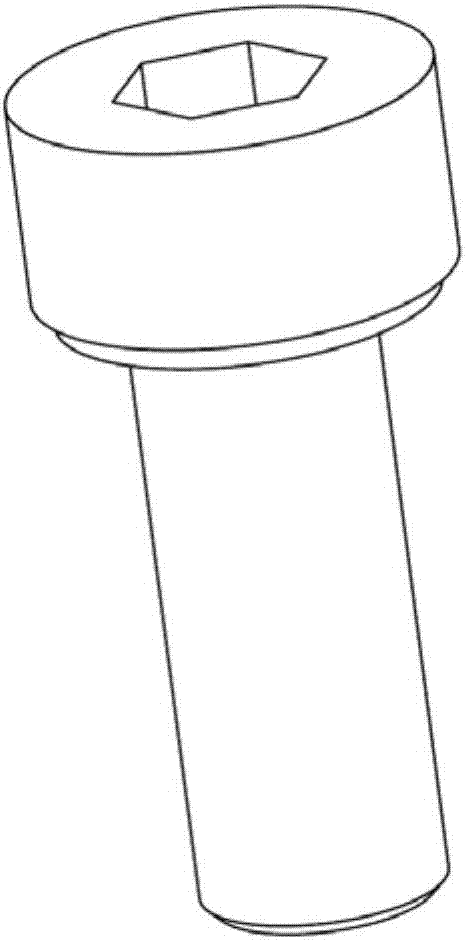

[0022] Preferably, the head of the hexagon socket head cap scr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com