Sealing and locking structure of pressure vessel

A technology of pressure vessel and locking structure, which is applied in the direction of pressure vessel, engine sealing, fixed capacity gas storage tank, etc., can solve the problem of heavy weight, high cost of pressure vessel, and difficulty in connecting and switching between the end of the high-pressure vessel and the top cover. and other problems, to achieve the effect of reducing weight, reducing operating costs, and alleviating the problem of thickness restrictions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] Below in conjunction with embodiment technical solution of the present invention is made more specific description:

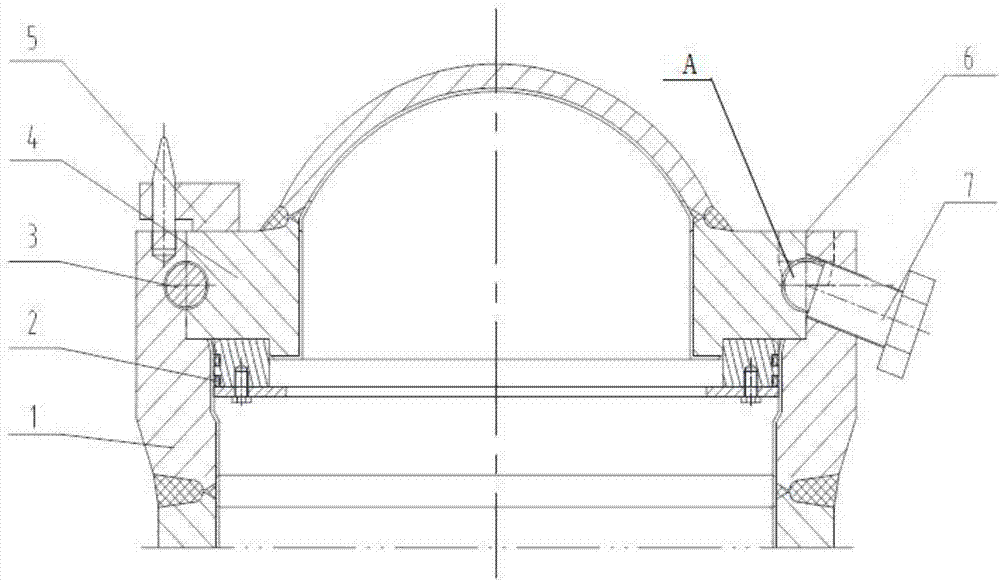

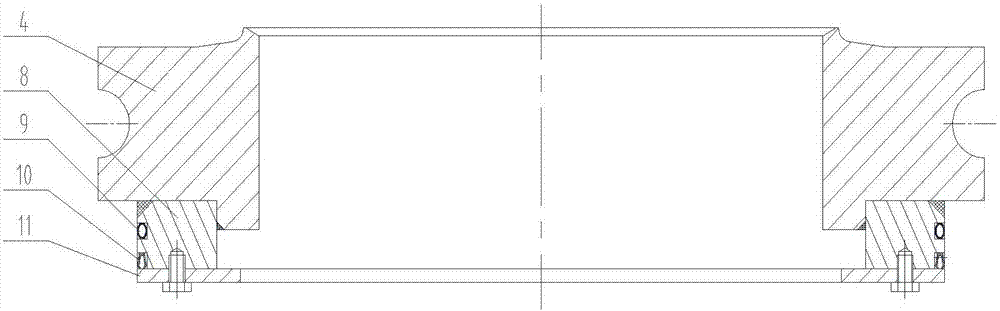

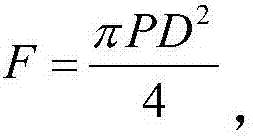

[0028] The present invention includes a first annular groove opened in the circumferential direction of the cylinder end 1 of the pressure vessel and a second annular groove formed in the circumferential direction of the top cover 4 of the pressure vessel, and the top cover 4 is installed on the The notch of the first annular groove and the second annular groove on the cylinder end 1 are opposite to each other and form an annular channel A with a circular cross section, which is filled with The cylinder end 1 and the top cover 4 realize the locked shear steel ball 3 . The present invention changes the locking structure types such as flange connection, clamp connection, shear bolt connection, shear pin connection and shear ring connection used in the previous sealing and locking structure, and adopts the type of shear steel ball 3 to carry out Locking, w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com