Double-loop water cooling unit and double-temperature cooling system

A chiller, dual-circuit technology, used in refrigerators, refrigeration components, compressors, etc., can solve the problems of high temperature user terminal temperature not easily guaranteed, difficult temperature, and high equipment cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

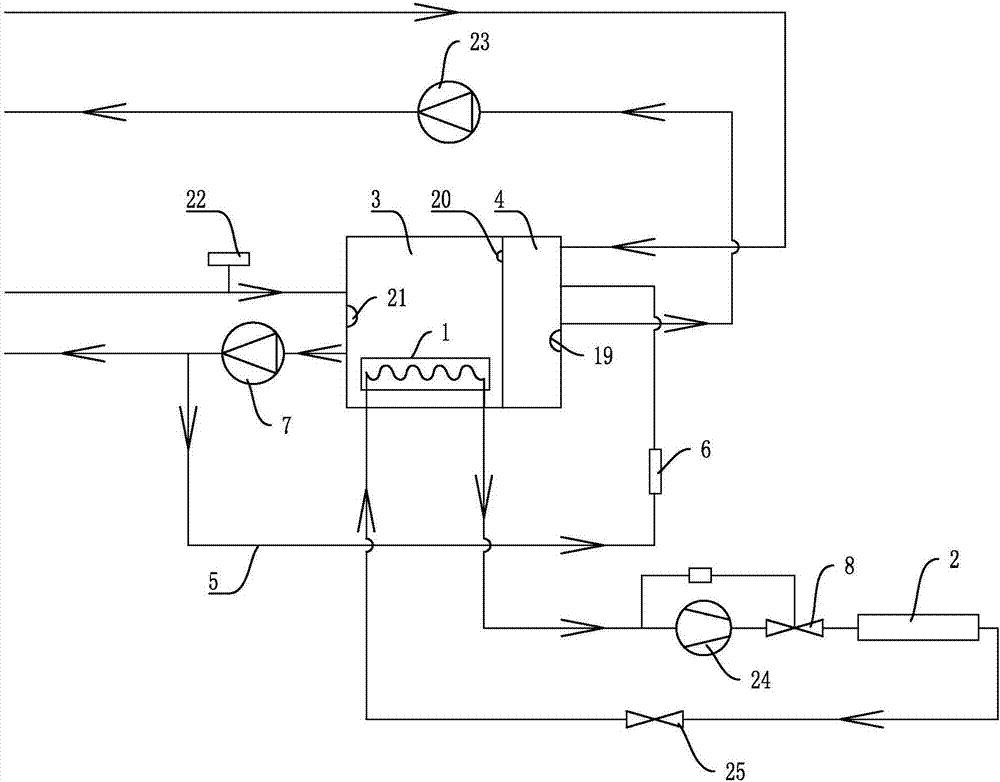

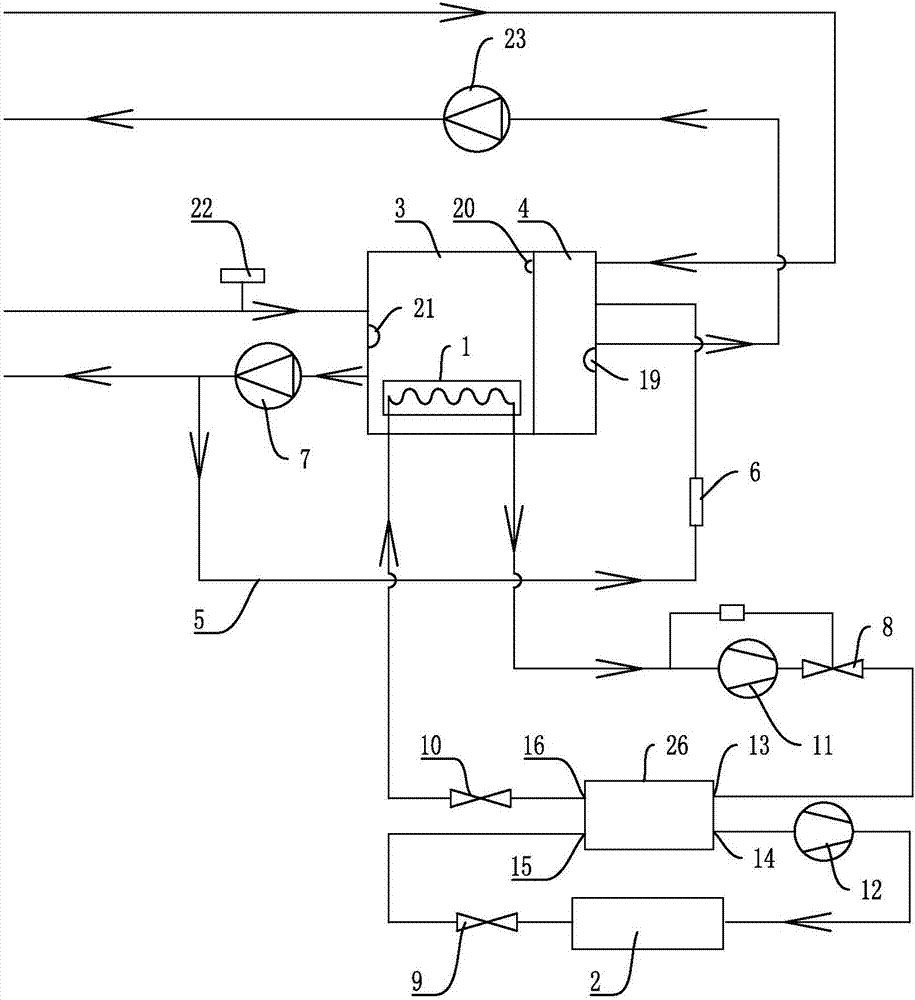

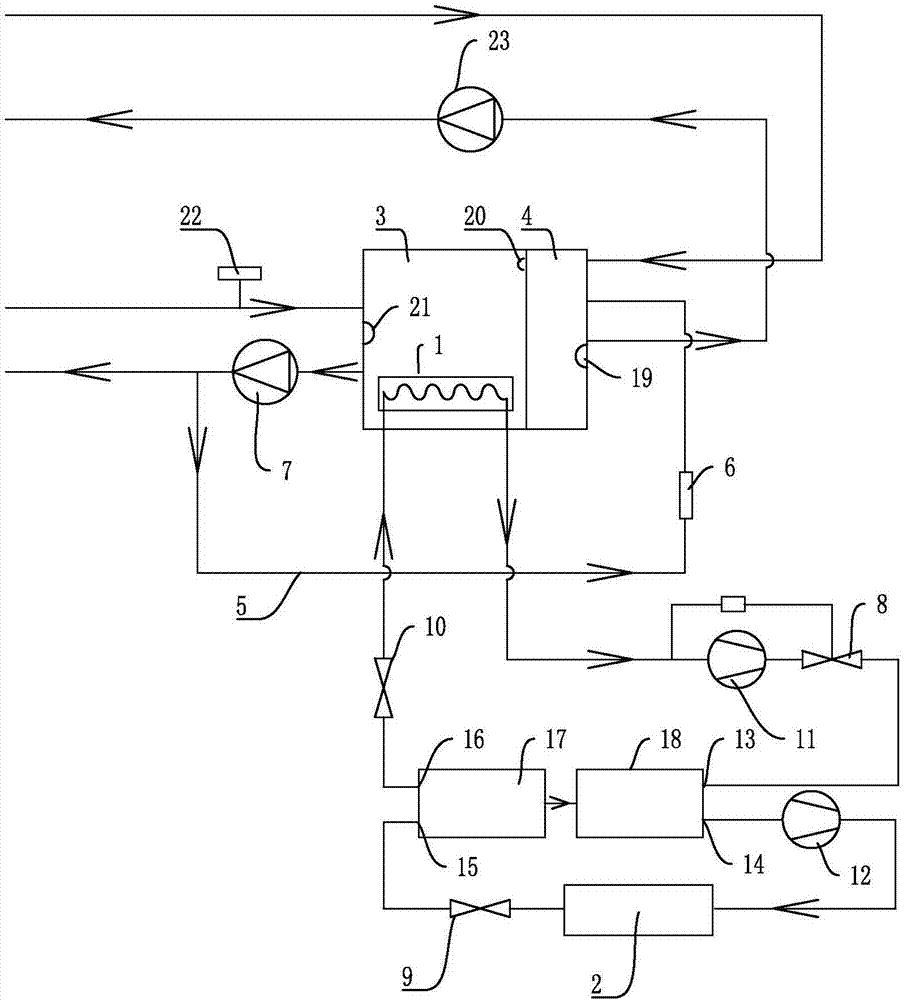

[0021] like Figure 1 to Figure 3 The shown dual-circuit chiller includes a water tank and a compression refrigeration cycle. The compression refrigeration cycle includes at least a compressor, an evaporator 1 , a condenser 2 , a throttle valve and pipelines connecting these components. The compression refrigeration cycle belongs to the usual technical means in the field and will not be described in detail here.

[0022] The water tank is divided into a main water tank 3 and an auxiliary water tank 4 by a vertical dividing plate. The above-mentioned evaporator 1 is located in the main water tank 3 and can cool the circulating water in the main water tank 3 . The main water tank 3 is externally connected with a low-temperature water circulation supply circuit. Since the evaporator 1 as a cold source is located in the main water tank 3, the cooled low-temperature water is transported to the user terminal with a lower demand temperature through the low-temperature water circulat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com