Limit sensing method

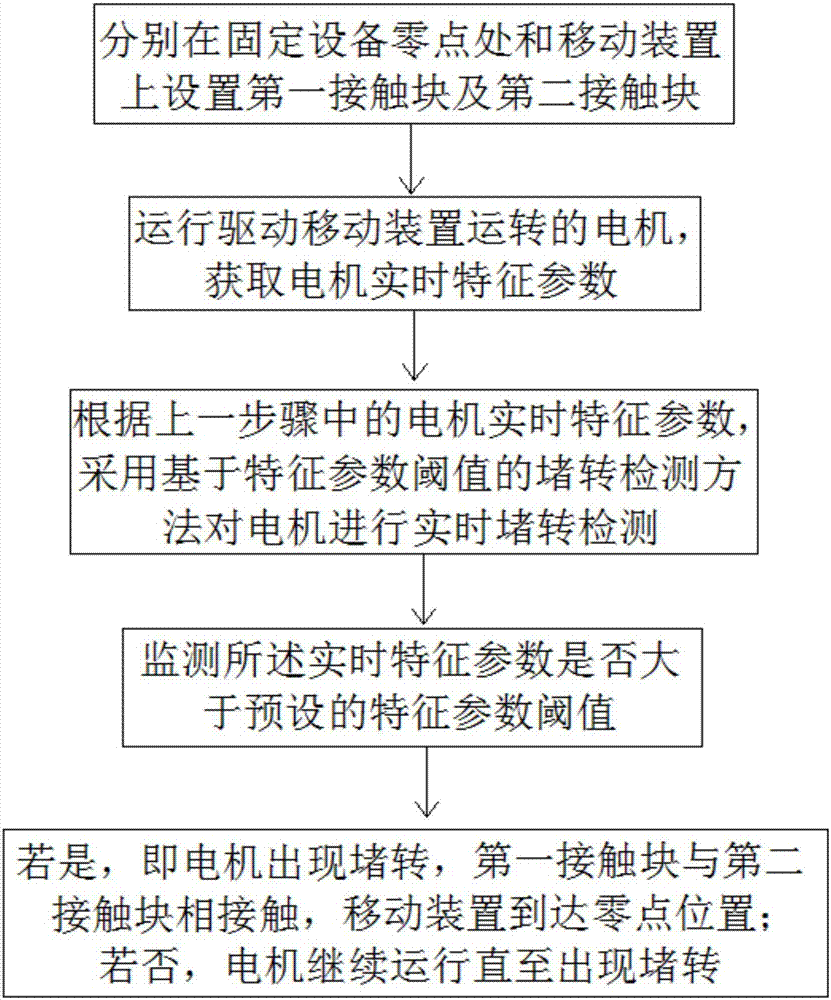

A sensing method and zero-point position technology, applied in the field of limit sensing, can solve the problems of normal operation interference of the workbench, occupying the space of the workbench, etc., and achieve the effect of saving use and optimizing the space structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0031] Taking the existing 3D printer equipment as an example, the motor is a stepping motor. A stepper motor is an actuator that converts electrical pulses into angular displacement.

[0032] The stepper motor adopts pulse width modulation subdivision drive circuit, which adds the control voltage output by DPA to the input end of the pulse width modulation circuit, and the pulse width modulation circuit converts the input control voltage into a rectangular wave with corresponding pulse width. The control of the on-off time of the power amplifier tube changes the average current output to the motor winding. Taking the rotation time of one step angle as the period T, within the detection period T, the duty cycle of the output level, the duty cycle of the output voltage in the normal working state is not more than 95%, and the duty cycle in the locked-rotor state is less than 95%. Greater than or equal to 99%.

[0033] In order to achieve the purpose of detection within one cy...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com