A kind of thin thermal battery separator and its preparation method

A spacer, thermal battery technology, applied in the direction of delayed action cells, etc., can solve the problems of electrolyte electrical noise, spacer diameter size limitation, poor high-power discharge capacity, etc., to achieve high-power discharge capacity and improve high-power discharge ability, the effect of facilitating mass production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

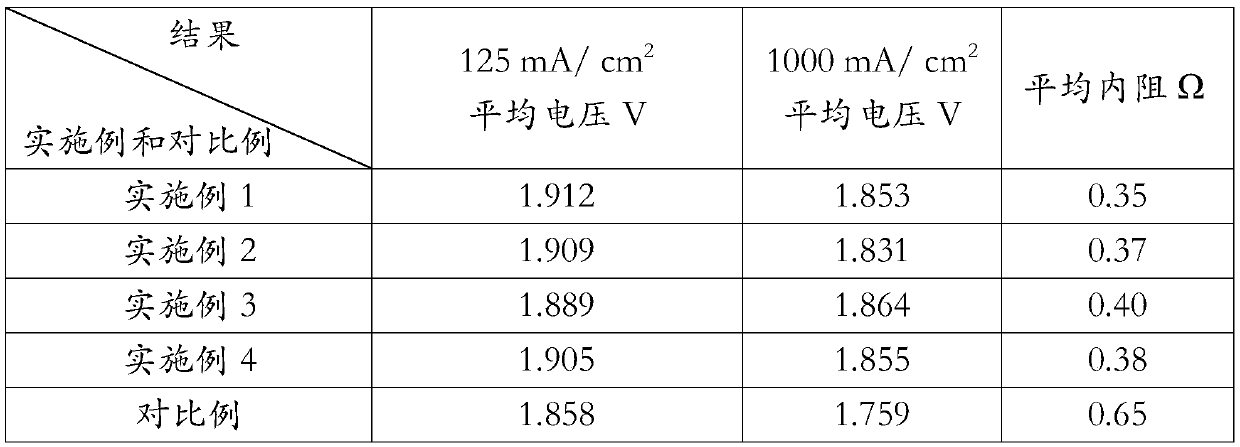

Examples

Embodiment 1

[0034] A preparation method of a thin thermal battery separator, comprising the following steps:

[0035] (1) Preparation of electrolyte salt saturated solution: in natural environment, mix electrolyte salt and dispersant, stir at 100°C, stirring speed is 200r / min, stirring time is 30min, obtain electrolyte salt saturated solution; wherein, dispersing The solvent is 50% absolute ethanol; the electrolyte salt is a mixture of KCl and LiCl, the mass percentage of KCl is 40%, the mass percentage of LiCl is 60%; the mass percentage of the electrolyte salt is 60%, and the mass percentage of the dispersant The content is 40%.

[0036] (2) In the natural environment, use glass fiber as the supporting matrix, immerse it in the electrolyte salt saturated solution, keep the temperature of the solution at 100°C for 30s, and then take it out to obtain the separator; the thickness of the glass fiber matrix is 100 μm, and the pore size 1.0 μm;

[0037] (3) In an environment with a humidi...

Embodiment 2

[0040] A preparation method of a thin thermal battery separator, comprising the following steps:

[0041] (1) Preparation of electrolyte salt saturated solution: in natural environment, mix electrolyte salt and dispersant, stir at 200°C, stirring speed is 600r / min, and stirring time is 1h, to obtain electrolyte salt saturated solution; among them, dispersing The agent is distilled water; the electrolyte salt is a mixture of KCl and LiCl, the mass percentage of KCl is 45%, and the mass percentage of LiCl is 55%; wherein, the mass percentage of the electrolyte salt is 15%, and the mass percentage of the dispersant is 85%;

[0042] (2) In the natural environment, use glass fiber as the supporting matrix, immerse it in the saturated solution of electrolyte salt, keep the temperature of the solution at 200 °C for 5 seconds, and then take it out to obtain the separator; the thickness of the glass fiber matrix is 200 μm, and the pore size 2.0 μm;

[0043](3) In an environment wit...

Embodiment 3

[0046] A preparation method of a thin thermal battery separator, comprising the following steps:

[0047] (1) Preparation of electrolyte salt saturated solution: in natural environment, mix electrolyte salt and dispersant, stir at 150°C, stirring speed is 300r / min, stirring time is 6h, obtain electrolyte salt saturated solution; wherein, dispersing Agent is distilled water; Electrolyte salt is the mixture of LiCl, LiBr and KBr, the mass percentage of LiCl is 10%, the mass percentage of LiBr is 40%, the mass percentage of KBr is 50%; Wherein, the mass percentage of electrolyte salt is 80% %, the mass percentage of dispersant is 20%;

[0048] (2) In the natural environment, use the metal oxide film as the supporting substrate, immerse it in the electrolyte salt saturated solution, keep the temperature of the solution at 150 ° C for 1 min, and then take it out to obtain the separator; the thickness of the metal oxide film is 110 μm , the pore size is 0.8 μm;

[0049] (3) In an ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com