Roll position detection system for rolling mill

A detection system and roll technology, applied in metal rolling, length measuring device, metal rolling, etc., can solve problems such as affecting production efficiency, detecting equipment failure, unable to monitor dynamic position changes of upper and lower rolls, etc., and achieve real-time and accurate control , the effect of efficient production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention will be further described below in conjunction with the drawings.

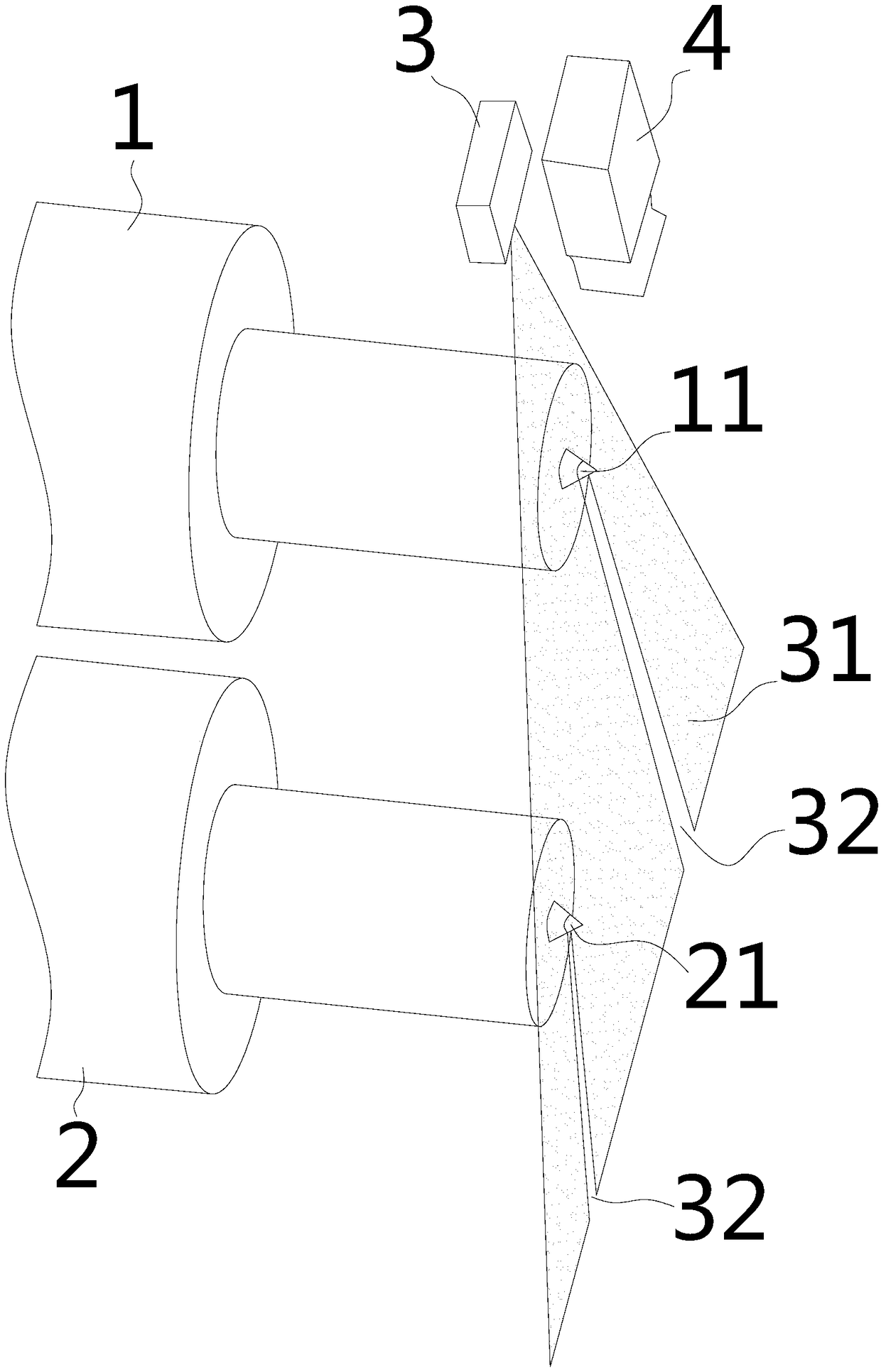

[0014] Such as figure 1 The roll position detection system of the rolling mill shown includes the upper roll 1 and the lower roll 2 to be detected, and includes a laser monitoring device. The upper roll 1 and the lower roll 2 are respectively provided with an upper roll cone 11 and a lower roll cone 11 at the same end. The roller cone 21, the light curtain 31 emitted by the laser monitoring device passes through the upper roller cone 11 and the lower roller cone 21 to form a light curtain shadow area 32. The laser monitoring device monitors the light curtain shadow area 32 and the light The change of the curtain 31 realizes the monitoring of the axial fluctuation of the upper roll 1 and the lower roll 2.

[0015] The invention uses the principle that the length of the laser line on the cone is changed when the roller moves in the bearing direction, and calculates the amount of movement...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com