Punching machine

A punching machine and lever technology, which is applied in metal processing and other directions, can solve the problems of slow punching frequency, poor mold coincidence accuracy, and unclean cutting of electric mechanical punching machines, and achieve the effects of small mold damage, low overall noise, and improved service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

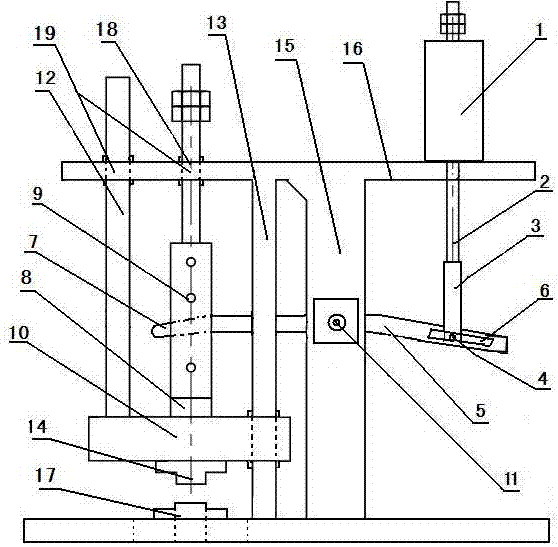

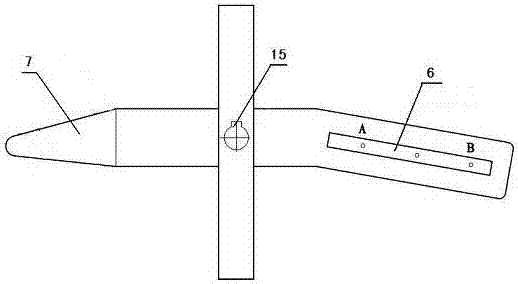

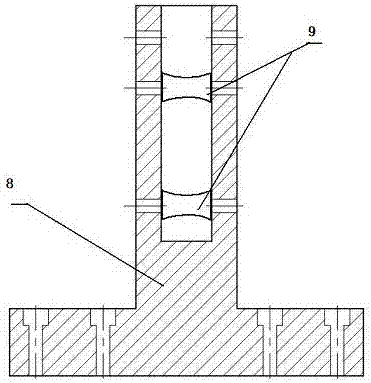

[0019] The present invention will be further described in detail in conjunction with the accompanying drawings.

[0020] to combine figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 It can be seen that the present invention is a punch press, which includes an air pump 1, a punch main frame 16, a lever system and a lower module 17, and the air pump 1, the lever system and the lower module 17 are installed on the punch main frame 16; the lever system is stretched by the air pump Rod 2, rolling pressure rod 3, lever 5, force balance bracket 15, vertical lifting mechanism, and upper module 14 constitute, air pump 1 is fixedly connected to air pump telescopic rod 2, one end of rolling pressure rod 3 is connected to air pump telescopic rod 2, rolling pressure rod 3 is another One end is movably connected to the chute 6 on one end of the lever 5, the lever 5 is used as a support point through the force balance bracket 15, and the other end of the lever 5 lifts the slideway ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com