Overlapped-type zero-leakage hydraulic lock valve

A zero-leakage, hydraulic lock technology, applied in the direction of fluid pressure actuators, servo motor components, mechanical equipment, etc., can solve the problem of increased volume of valve blocks installed in superimposed valves, heavy processing workload, leakage of superimposed hydraulic lock valves, etc. problems, to achieve the effect of convenient and standardized design, material saving, and no offset position maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

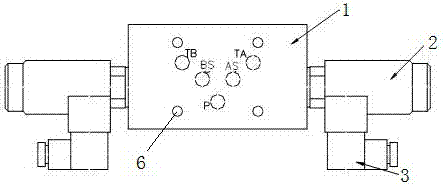

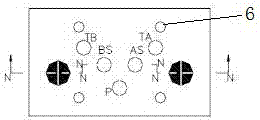

[0019] The existing stack valve is installed on the stack valve block. In order to achieve zero leakage, another valve hole needs to be designed on the stack valve block to install the plug-in zero-leakage hydraulic lock valve, but this design leads to the processing of the stack valve block. The workload is large, the volume is large, and it is not convenient for standardized design. In order to solve the above problems, this embodiment provides a superimposed zero-leakage hydraulic lock valve, such as figure 1 As shown, including the installation valve block 1, the installation valve block 1 has six surfaces, and a pair of opposite surfaces are vertically provided with a cartridge valve hole, respectively, the first cartridge valve hole CA and the second cartridge valve hole CB, Two plug-in valve holes are arranged opposite to each other, and a plug-in zero-leakage hydraulic lock valve 2 is inserted in CA and CB respectively, and each plug-in zero-leakage hydraulic lock valve...

Embodiment 2

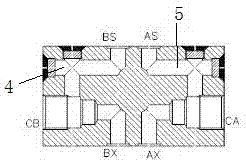

[0025] On the basis of Example 1, such as image 3 As shown, the third port and the fourth port of the first cross hole 4 and the third port and the fourth port of the second cross hole 5 are all equipped with oil plugs. The above-mentioned ports are for the convenience of opening two cross holes for technical considerations, while the oil plug is used for isolation. The use of the oil plug not only solves the problem of the process, but also blocks all port to prevent oil leakage.

Embodiment 3

[0027] On the basis of Example 1, it needs to be further explained that the choice of material determines the pressure resistance level of the valve block, and at the same time the choice of material determines the manufacturing cost of the valve block. Under the condition of meeting the pressure requirements, try to use low-cost In order to save costs, the following principles are generally followed: when the working pressure P<6.3MPa on the installation valve block 1, the installation valve block 1 is made of cast iron HT20-40. When the working pressure of the installed valve block 1 is 6.3MPa≤P<21MPa, the installed valve block 1 is made of aluminum alloy forging or No. 20 forged steel or Q235; when the working pressure of the installed valve block 1 is P≥21MPa, The installation valve block 1 is made of No. 35 forged steel.

[0028] The superimposed zero-leakage hydraulic lock valve provided by the present invention includes a plug-in zero-leakage hydraulic lock valve and an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com