Method for detecting stem portion precision of valve stem

A technology of precision detection and valve stem, applied in the direction of mechanical roughness/irregularity measurement, measuring device, mechanical measuring device, etc., can solve problems such as difficult to meet product quality requirements, increase production cost, increase product error rate, etc., to achieve Accurate and reliable test results, improve product accuracy, and improve product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

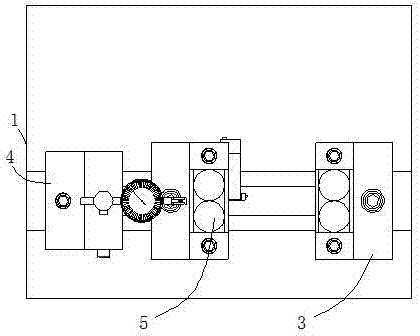

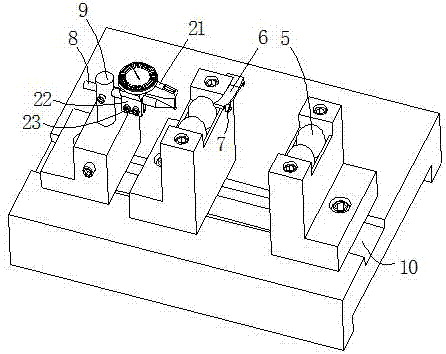

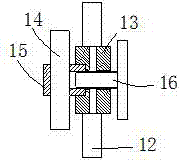

[0045] A method for detecting the accuracy of the stem portion of a valve stem, including the step of detecting the flatness of the end surface of the stem portion of the valve stem. The two sides of the lower part of the circumferential surface of the rod contact to realize the support positioning, and the end face of the rod is used to limit the contact of the end face of the rod, and then the measuring head of the lever dial gauge is used to contact the end face of the valve rod after positioning, and then rotate The valve realizes the detection of the flatness of the end surface of the valve stem; the support member on the peripheral surface of the stem is obtained by using equal and horizontally arranged paired spheres.

[0046] In this way, the method includes the step of detecting the flatness of the end surface of the valve stem part, and wherein the horizontally paired spheres are used to support the valve stem part, so that when the rotation is detected, the stem part...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com