Pressure sensor with variable sense gap

一种压力传感器、传感器装置的技术,应用在测量流体压力、利用电容变化的流体压力测量、测量力等方向,能够解决增强的灵敏度难等问题

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

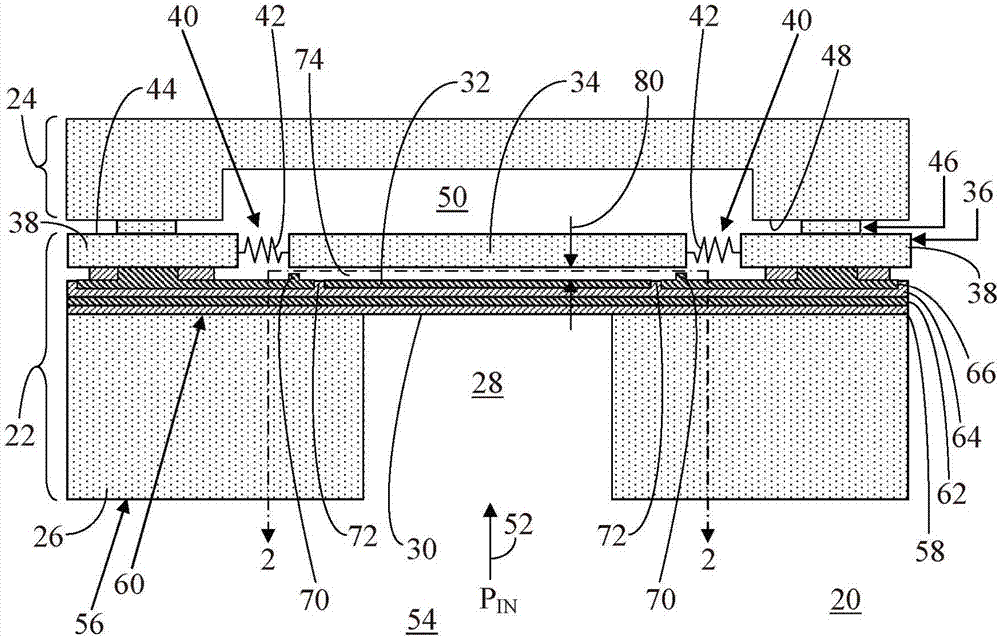

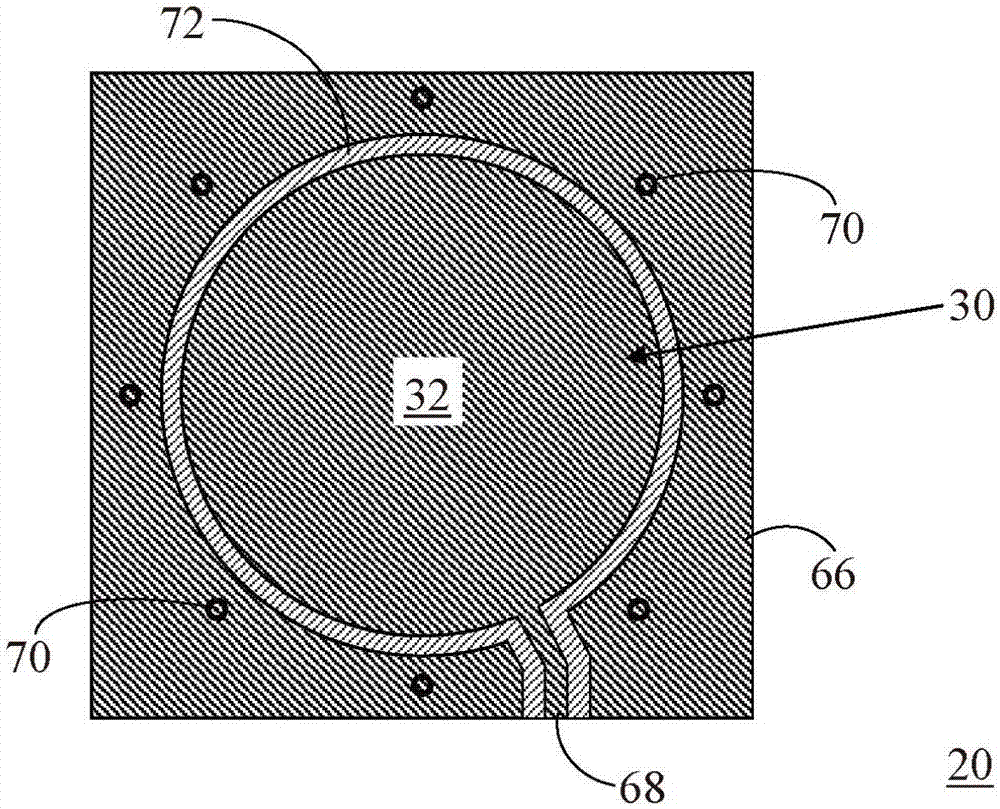

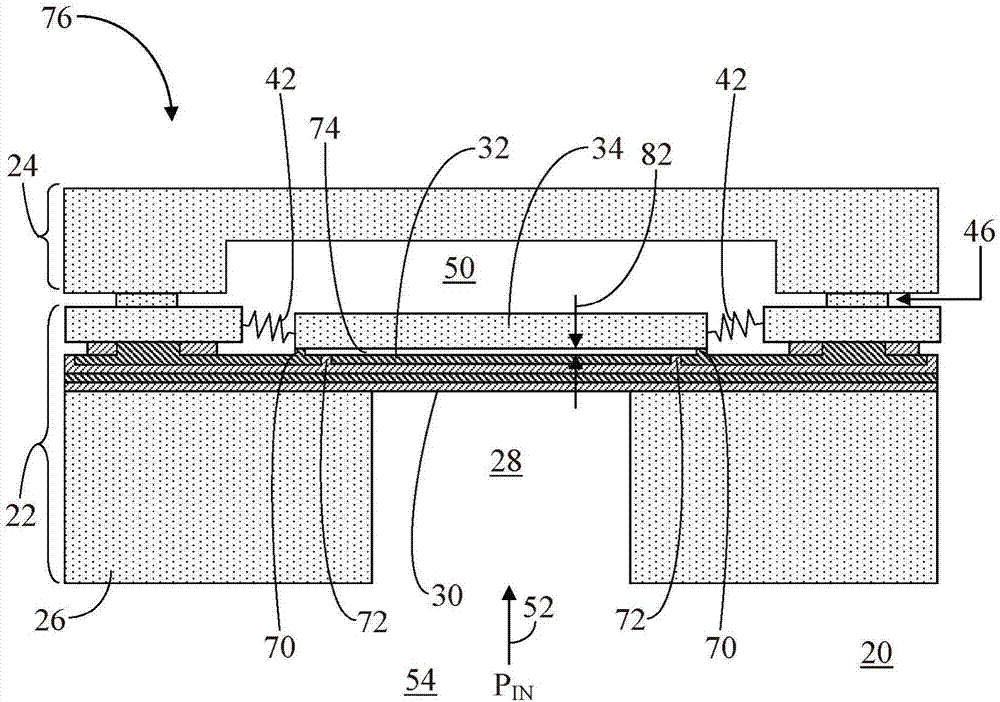

[0035] Embodiments of the invention include a pressure sensor device with a variable sense gap and a method for operating the pressure sensor device. More specifically, a variable sensing gap between two electrodes, one of which is part of the diaphragm, is achieved by enabling the other electrode to move between at least two positions. In this way, the width of the sensing gap can be reduced, thereby effectively increasing the sensitivity of the pressure sensor device to pressure stimuli. The structure of the pressure sensor device may more easily enable the integration of high sensitivity pressure sensors into an integrated miniaturized sensor package for efficiency improvements, cost savings, and the like.

[0036] This disclosure is provided to explain, in addition to enabling, the best modes of making and using various embodiments in accordance with the invention when applicable. This disclosure is also provided to enhance understanding and appreciation of the inventive ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com