Motor rotor paint spraying device

A motor rotor and turntable technology, which is applied to spray devices, devices that apply liquid to surfaces, coatings, etc., can solve problems such as environmental pollution, low efficiency, and affect the health of workers, improve spraying efficiency, and ensure filtration. effect of effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be further described below in conjunction with the accompanying drawings.

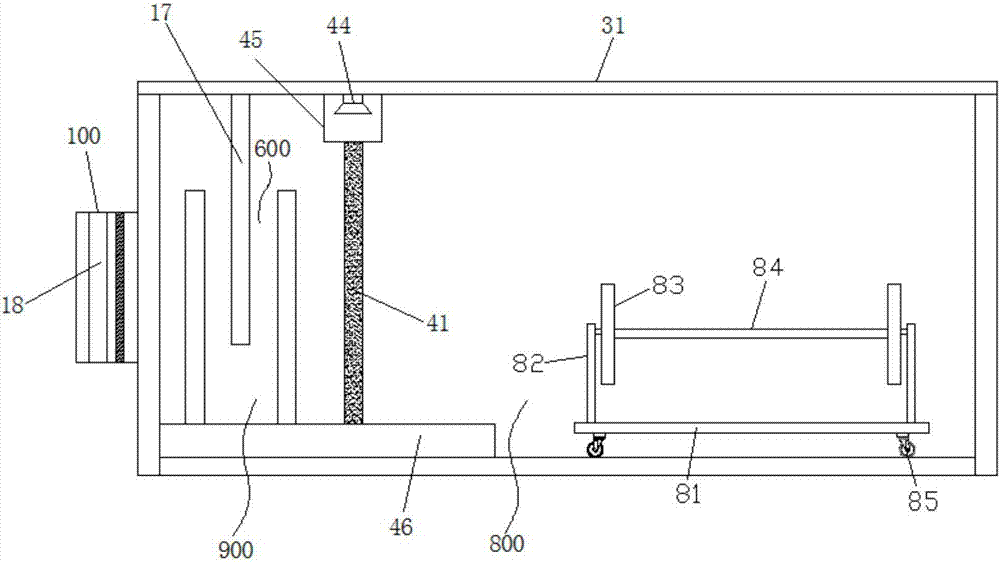

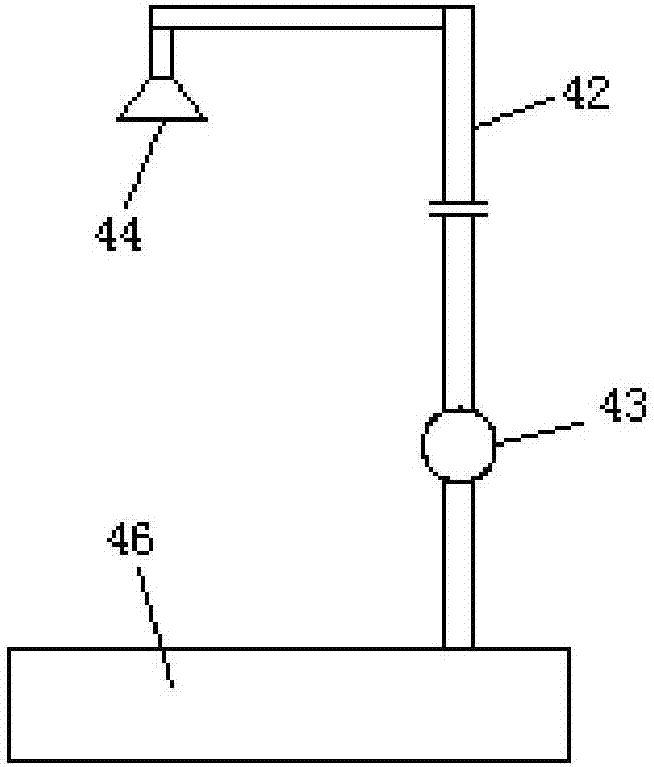

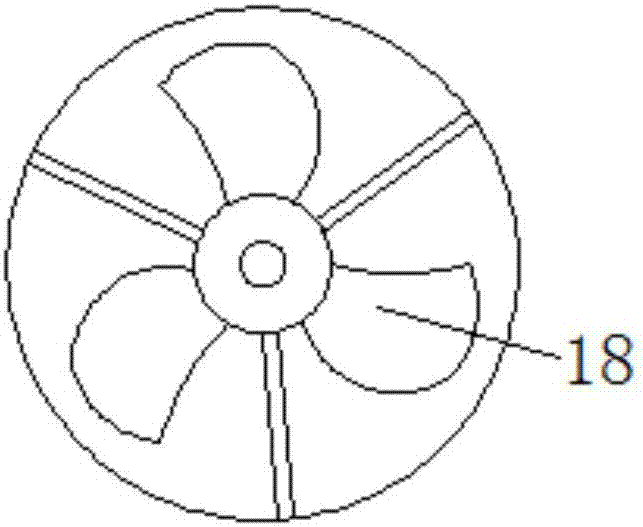

[0026] Such as Figure 1 to Figure 6 As shown, the present invention discloses a motor rotor painting device, which includes a partition 17, an exhaust fan 18, a chamber body 31, a water curtain plate 41, a water spray pipe 42, a circulating pump 43, a water spray head 44, a water collection tank 46, and a support base plate 81. Support pole 82, turntable 83, connecting shaft 84 and fixed buckle 9, the water curtain plate 41 is arranged in the chamber body 31, and the water curtain plate 41 divides the inner cavity of the chamber body 31 into a paint spray chamber 800 and a purification chamber 900 , the water spray head 44 is arranged on the top of the water curtain plate 41, and the water spray head 44 links to each other with the circulation pump 43 through a water spray pipe 42, and the circulation pump 43 links to each other with the water collection tank 46 throu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com