Double-face synchronous positioning device for machining of bearing block numerical control milling machine

A CNC milling machine and synchronous positioning technology, applied in metal processing equipment, metal processing machine parts, manufacturing tools, etc., can solve problems such as easy misalignment of workpieces, easy movement of positioning sleeves, and affecting processing quality, so as to achieve fast positioning and improve fixation The effect of limit function and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The technical solution of this patent will be further described in detail below in conjunction with specific embodiments.

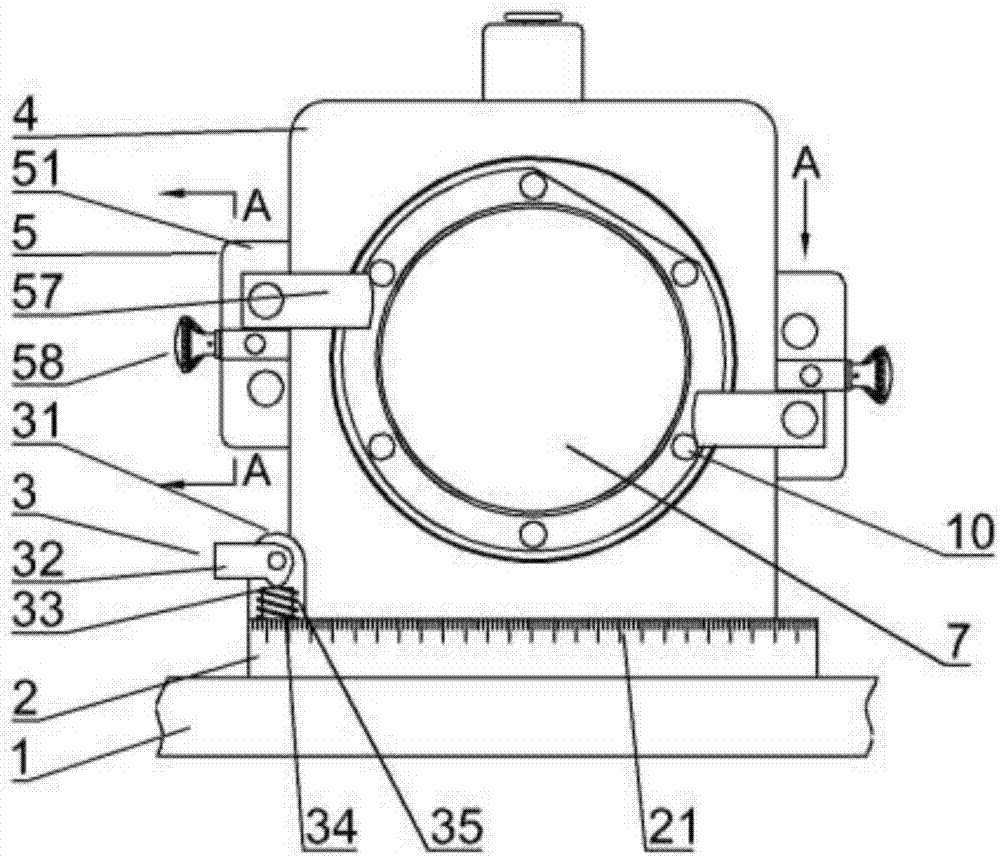

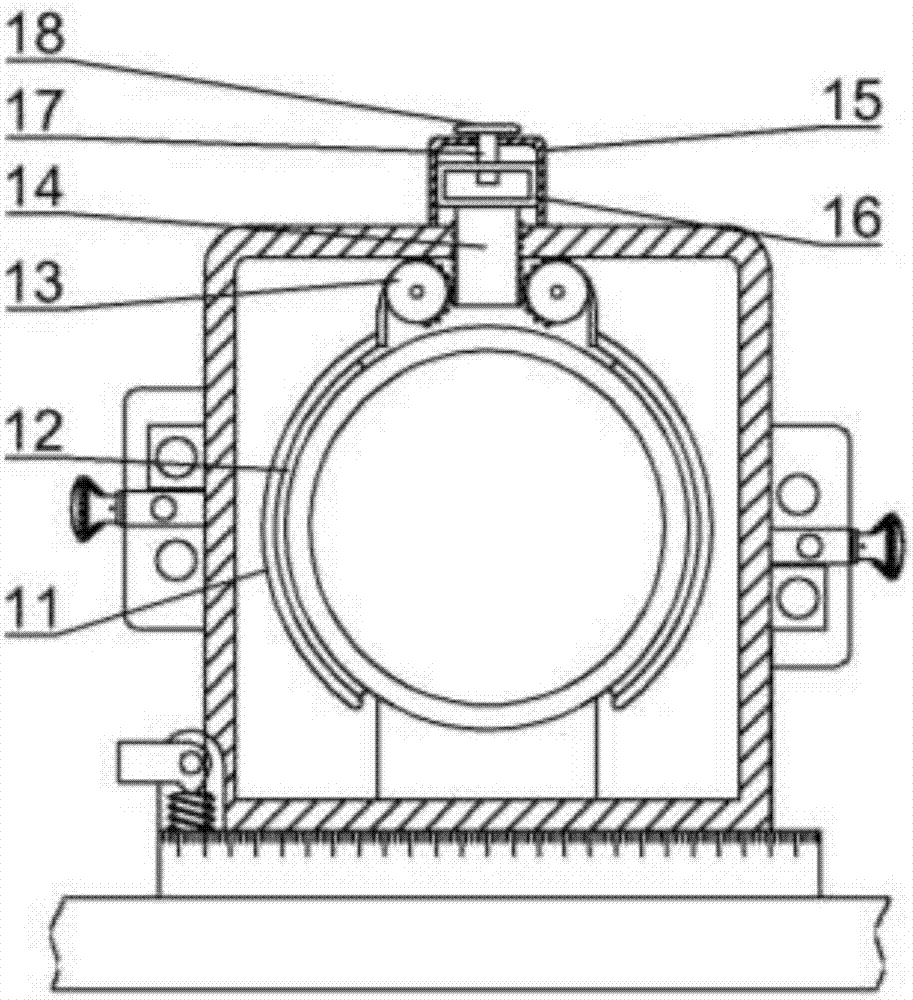

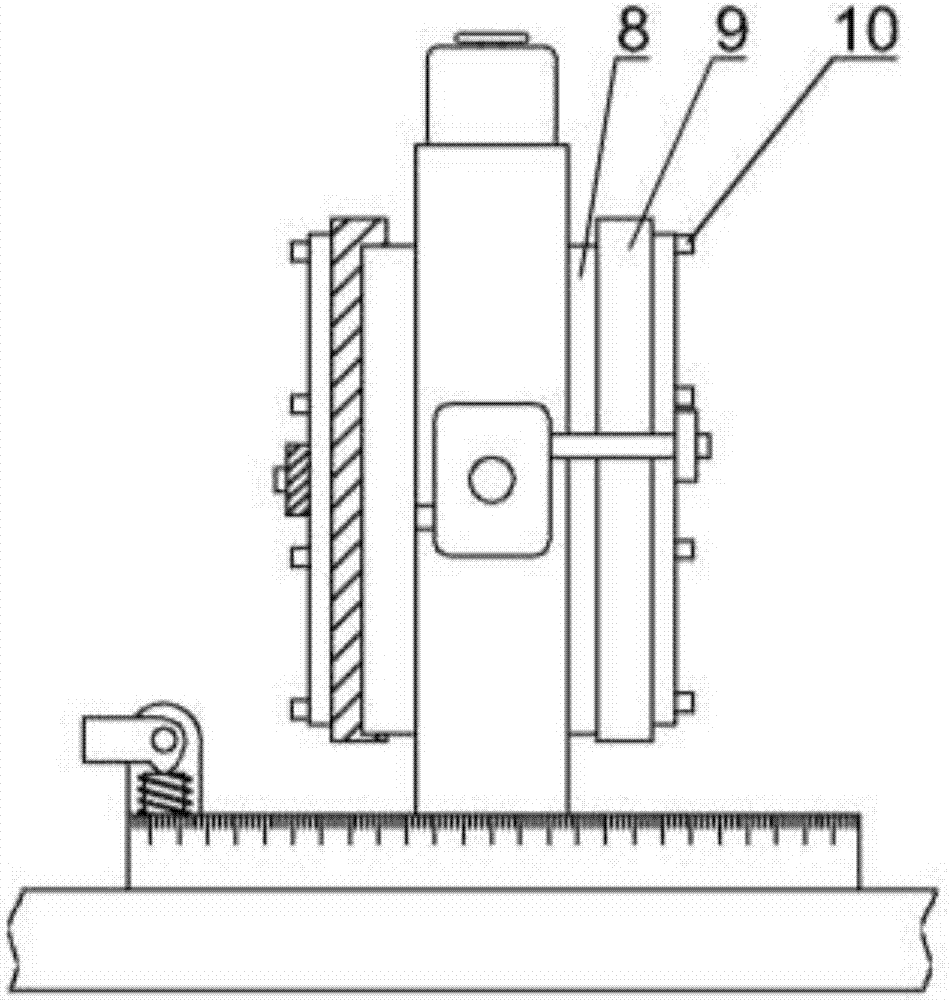

[0021] see Figure 1-5 , a double-sided synchronous positioning device for bearing seat CNC milling machine processing, including a processing table 1, a rotating mounting table 2, a fixed block 4, a positioning pin 10 and a double-sided limiting device 5, and the upper part of the processing table 1 is provided with a rotating Mounting platform 2, fixed block 4 is fixedly connected in the middle of the upper part of rotating mounting table 2, and the top of described rotating mounting table 2 is provided with manual pressing device 3, and described fixing block 4 is the shape of hollow and the middle of fixing block 4 is opened There are installation through holes 7, and the front and rear side walls of the fixed block 4 are respectively fixedly connected with annular protrusions 8, and the outer side of the annular protrusions 8 is provided with ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com