Integral solvent-free compound machine

A solvent-free composite machine and integrated technology, applied in the field of composite machines, can solve the problems of large occupied area, large frame structure, scattered layout of various components, etc., and achieve the effect of compact layout and small occupied area of the structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

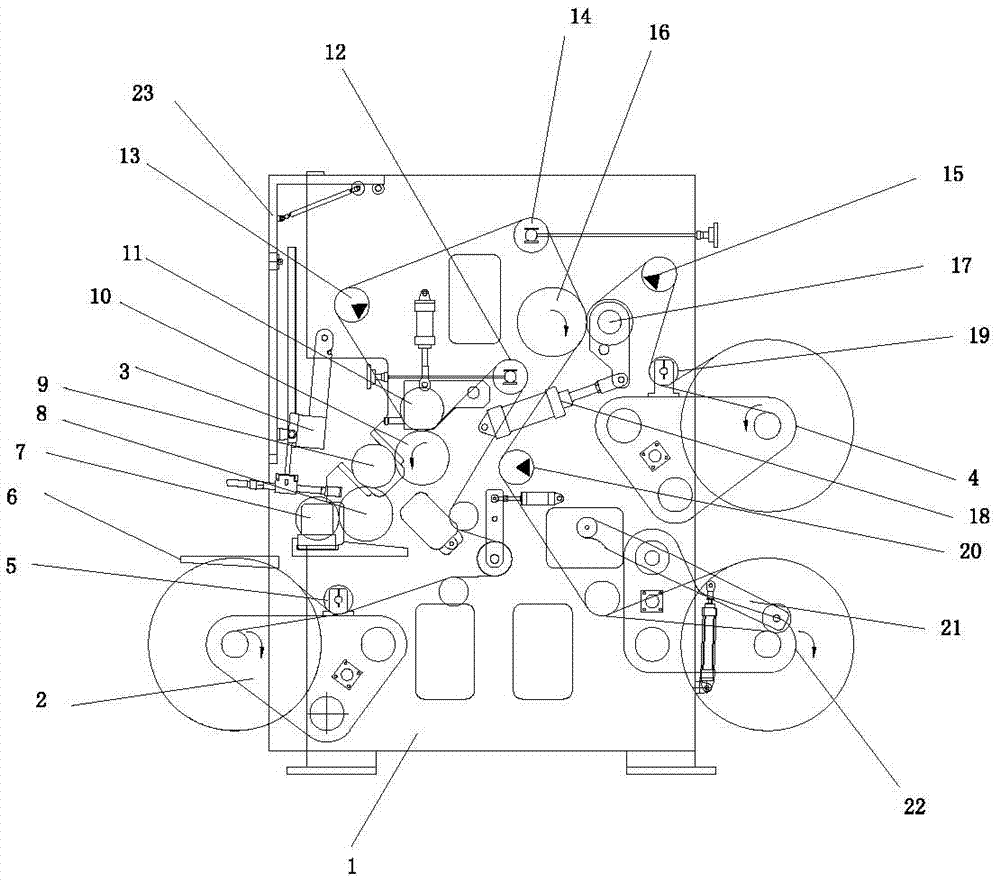

[0012] Depend on figure 1 Shown, the present invention comprises frame 1, is provided with the first unwinding mechanism 2, transfer glue mechanism, coating mechanism, glue mixing moving mechanism 3 and the first adjusting mechanism successively at the left end of frame 1 from bottom to top, on machine The right end of the frame 1 is provided with a second adjustment mechanism, a composite mechanism, a second unwinding mechanism 4, and a winding mechanism from top to bottom, and a first deviation correction roller 5 is provided on the first unwinding mechanism 2, and on the frame 1 On the top and at the upper end of the first unwinding mechanism 2, there is a gluing baffle plate 6, the transfer glue mechanism includes a metering roller 7, a transfer steel roller 8 and a transfer rubber roller 9, and the coating mechanism includes a coating pressure roller 10 and a coating steel roller 11, the first adjustment mechanism includes a first adjustment roller 12 and a first tension ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com