Rail linear control method for multi-line high speed railway bridge

A technology of alignment control and high-speed railways, applied in the field of bridge engineering, can solve problems such as difficult construction, difficult control of track alignment, poor economy, etc., and achieve the effect of reducing the influence of alignment, good alignment, and ensuring uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

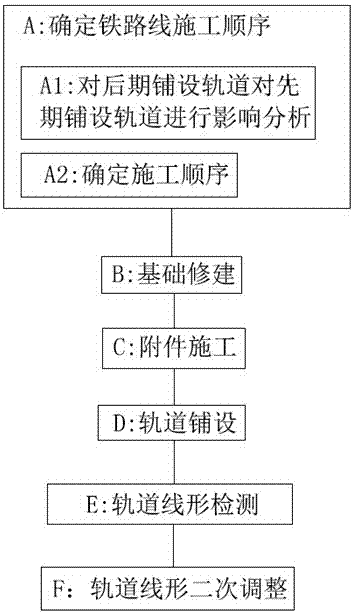

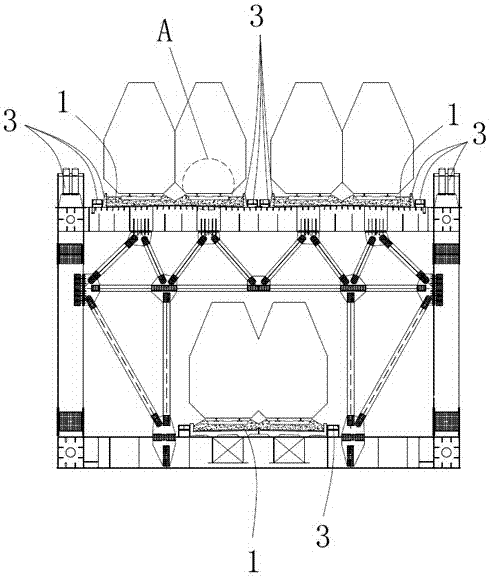

[0039] Specific implementation methods, such as Figure 1-3 as shown,

[0040] A track alignment control method for a multi-track high-speed railway bridge: comprising the steps of:

[0041] A: Determine the construction sequence of railway lines: determine the construction period of each railway line of the multi-line railway;

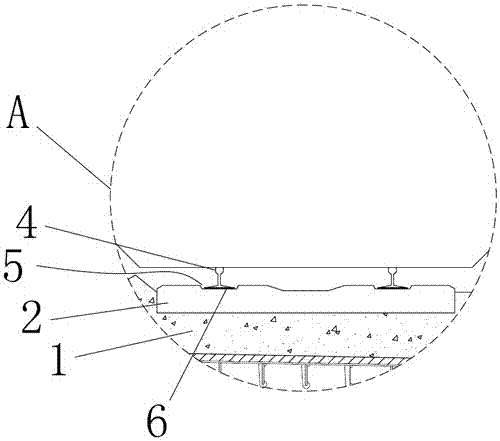

[0042] B: foundation construction: build the girder body and bridge deck of the high-speed railway bridge, and pour the ballast bed 1 on the bridge deck and set the sleeper 2 on the ballast bed 1, the ballast bed 1 in this step is the ballast bed 1 of all railway lines, in this step The sleeper 2 is the sleeper 2 of all railway lines;

[0043] C: Construction of Annex 3: Arrange other Annex 3 at the design position except for the track and the components used to fix the track. The Annex 3 is a dead-load component located on the foundation in the railway line;

[0044] D: Laying of track 4: According to the construction period of the railway line de...

Embodiment approach

[0046] Further, as an implementation mode, the step A includes the following steps:

[0047] A1: Modeling and analysis of the degree of influence of the later laid track 4 on the line shape of the earlier laid track 4: establish a corresponding model, design different railway line construction sequences, and analyze the construction sequence of various railway lines, the latter laying of the earlier railway line The degree of influence of the track 4 alignment of the railway line;

[0048] A2: Determine the construction sequence: According to the degree of influence of each railway line determined in step A1, sort from high to low to obtain the laying sequence of each railway line.

[0049] In the above method, the multi-line high-speed railway bridge is modeled and analyzed, and then the construction sequence of each railway line is obtained. The track 4 of the railway line that has the greatest influence on the alignment of the laid track 4 is laid first, and the laid track ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com