Online degritting device at bottom of horizontal-type oil-gas-water three phase separator and degritting method

A three-phase separator, oil-water separation technology, applied in separation methods, chemical instruments and methods, liquid separation, etc., can solve problems such as the inability to ensure the effective removal of deposited solid impurities, the inability to enter the sand removal space, and the lack of consideration of jet nozzles. , to reduce the cost of human intervention, smooth the sand removal process, and reduce the risk of clogging the sand outlet.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0046] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments, so that those skilled in the art can better understand the present invention and implement it, but the examples given are not intended to limit the present invention.

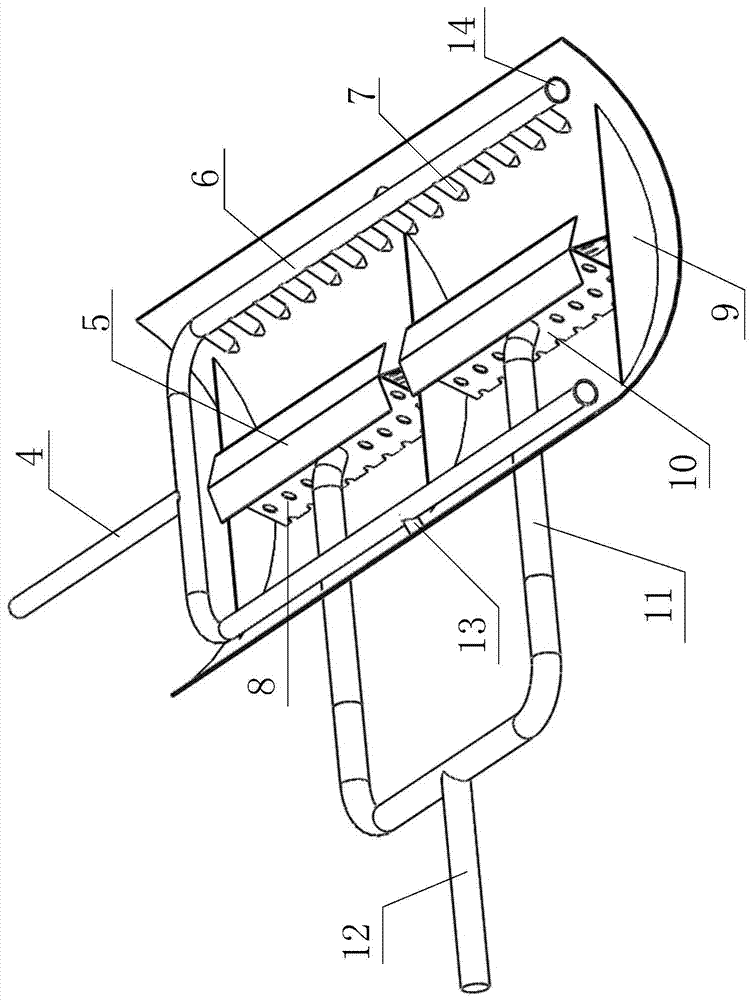

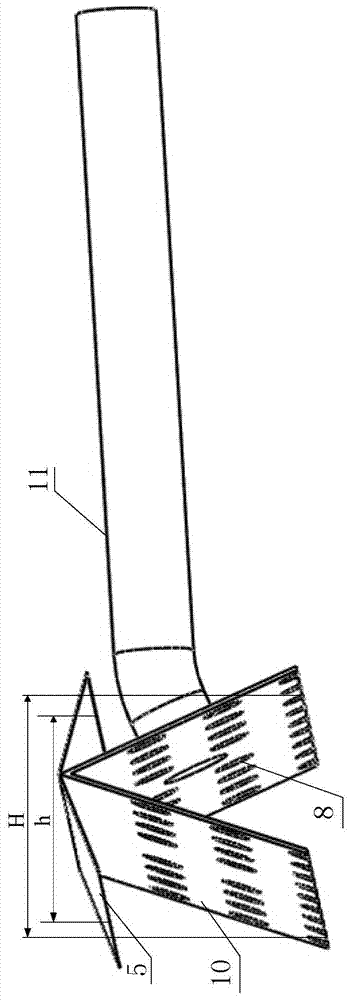

[0047] Such as figure 1 As shown, the online desanding device 1 at the bottom of a horizontal oil-gas-water three-phase separator of the present invention includes a sand separating plate 9, a sand gathering plate 10, a disturbance hole 8, a flow stabilization plate 5, a sand suction pipe 11, a suction Sand manifold 12, water inlet main pipe 4, water inlet branch pipe 6, jet nozzle 7, etc.

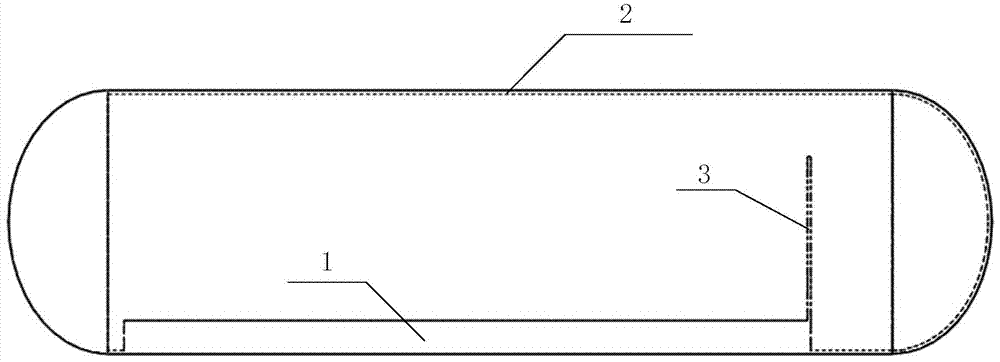

[0048] combine image 3 As shown, the horizontal oil-gas-water three-phase separator 2 is provided with an oil pool partition 3, which divides the inside of the horizontal oil-gas-water three-phase separator into an oil-water separation area (corresponding to the water inlet side) and an oil ac...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com