Coal seam interior gas parameter measuring probe and using method thereof

A parameter measurement and probe technology, which is applied in the field of coal mines, can solve problems such as heavy workload, heavy construction workload, and long measurement cycle, and achieve the effect of improving the success rate, reducing the workload, and shortening the measurement cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

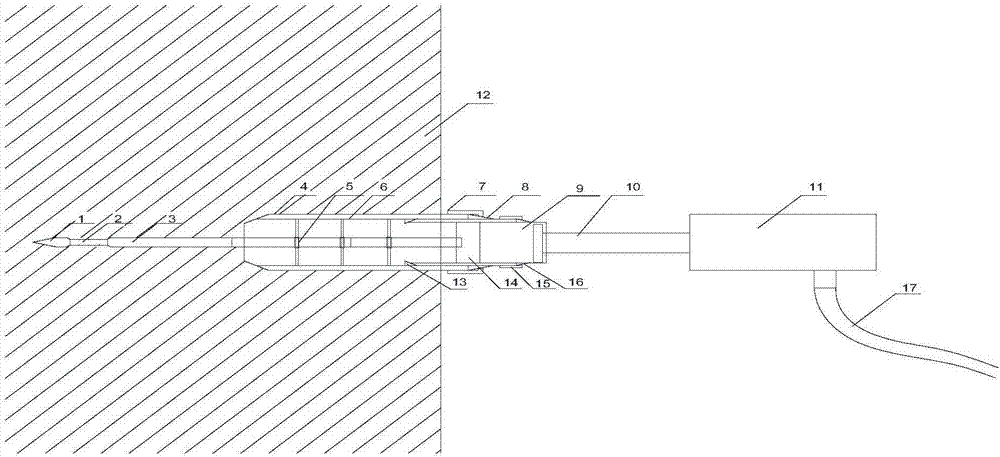

[0039] The invention provides a probe for measuring gas parameters in a coal seam and a method for using the same, which are combined below Figure 1 to Figure 7 The structure schematic diagram of the present invention is described.

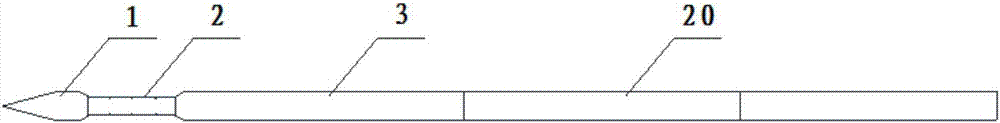

[0040] Such as Figure 1 to Figure 7 As shown, the present invention provides a gas parameter measurement probe in a coal seam and its use method, which includes a cone head 1, a piezometric tube 2, a first probe main tube 3 and a plurality of first probe heads that are detachably connected in sequence from left to right Two probe supervisors 20 .

[0041] Further, the detachable connection is threaded, and all threads are coarse threads, and the pitch and thread height of all threads are the same.

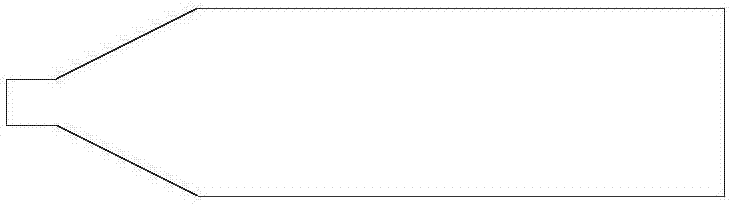

[0042] Further, the conical head 1 includes a conical end, a cylindrical section and a connecting section that are fixed in sequence, the conical angle of the conical end is <45°, the outer diameter of the cylindrical section is 10-15mm, and the le...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Outer diameter | aaaaa | aaaaa |

| The inside diameter of | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com