Small pipe diameter drainage pipeline pipe jacking machine tool and pipe jacking construction method

A technology for drainage pipes and small pipe diameters, which can be used in tunnels, earthwork drilling, directional drilling, etc., and can solve problems such as inability to jack into small pipe diameters

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

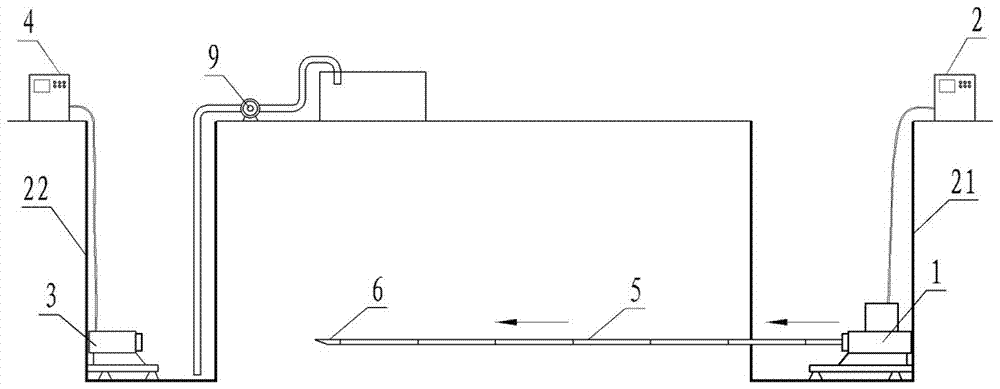

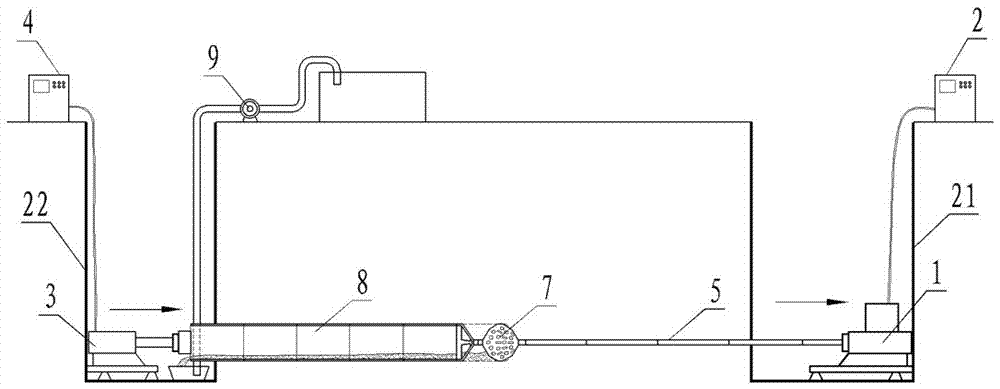

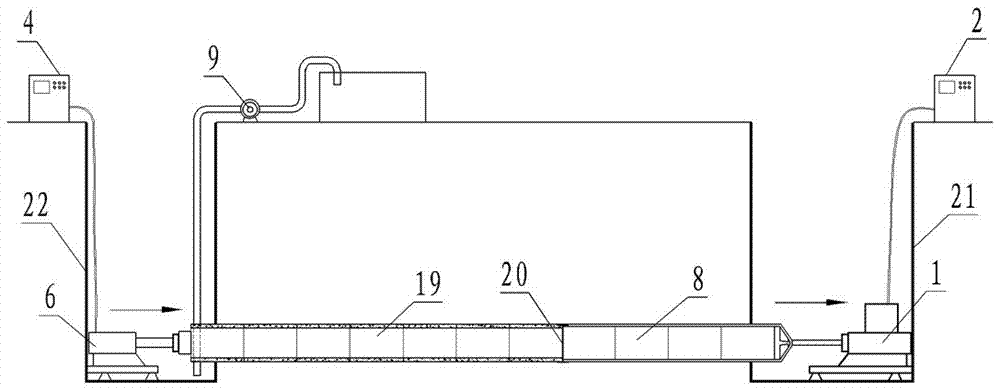

[0026] The present invention is a two-way jacking construction method, which is divided into three steps: drilling pipe jacking, back dragging reaming jacking conduit, and jacking pipe joints, respectively see figure 1 , figure 2 , image 3 . Pipe jacking equipment for small diameter drainage pipes, mainly composed of directional drill 1, directional drilling console 2, pipe jacking machine 3, pipe jacking machine console 4, drill pipe 5, drill bit 6, reamer 7, conduit 8, mud system 9 components, the directional drill 1 has jacking and pulling bidirectional power, and the directional drill 1 is equipped with a jacking direction monitoring system. The front end of the drill bit 6 is provided with an inclined guide surface 10, the rear end of the drill bit 6 is equipped with a calibrator 11, and the calibrator 11 is provided with a light target 12 towards the direction of the directional drill 1, and the directional drill 1 and the drill bit 6 are connected by a hollow drill ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com