High beam and low beam integrated LED headlamp

A technology for LED lamps and headlamps, applied in the field of vehicle lighting, can solve the problems of easy aging of materials of composite ellipsoid reflectors, processing cost, high difficulty in manufacturing process, failure and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

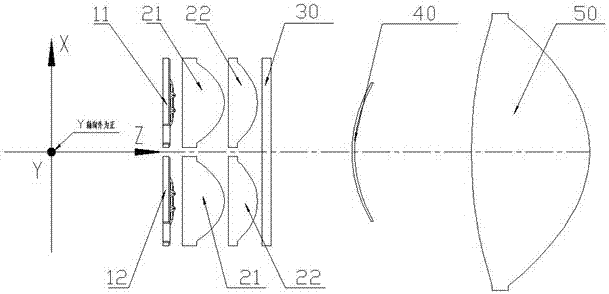

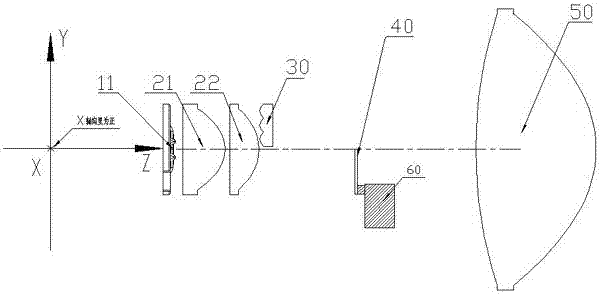

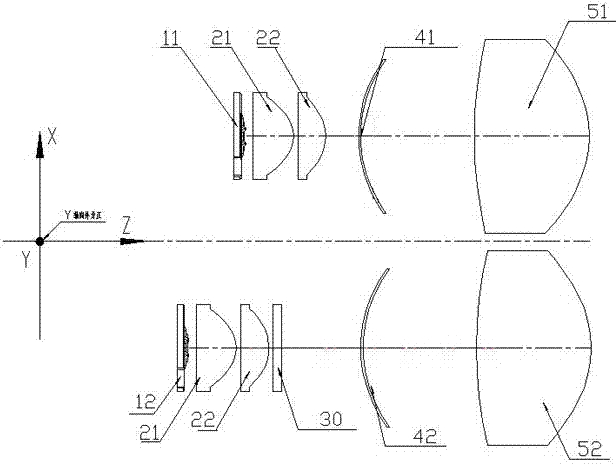

[0020] The distance-near integrated LED headlamp proposed in the present invention includes an LED light source, a lens group, a light distribution unit, a movable cut-off light barrier and a condenser lens arranged in sequence. In the present invention, we define the direction from the LED light source to the condenser lens as Z Axis, the focal length of the lens group falls on the optical axis of the corresponding LED light source, that is, in the direction parallel to the Z axis. The light distribution unit and the movable cut-off light barrier are located on the upper and lower sides of the optical axis of the LED light source. The up and down direction perpendicular to the optical axis of the LED light source is set as the Y axis, and the left and right direction perpendicular to the optical axis of the LED light source is set as the X axis.

[0021] The LED light source selected in the present invention provides sufficient luminous flux, and through the light distribution de...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Heat resistant | aaaaa | aaaaa |

| Radius | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com