A portable high-precision coaxiality measuring device

A coaxiality measurement, high-precision technology, used in measuring devices, optical devices, instruments, etc., to achieve the effect of convenient seal selection and consistent working pressure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

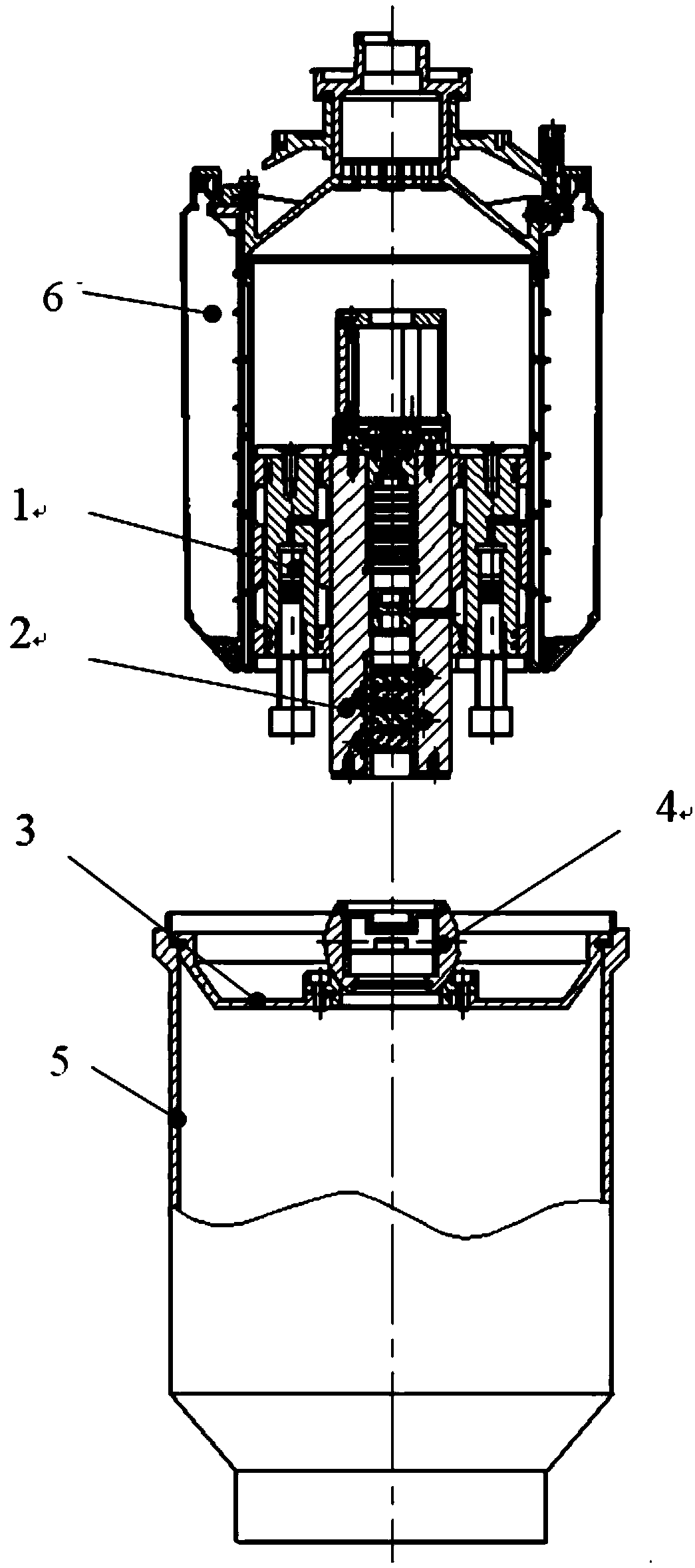

[0031] 1) Overall composition

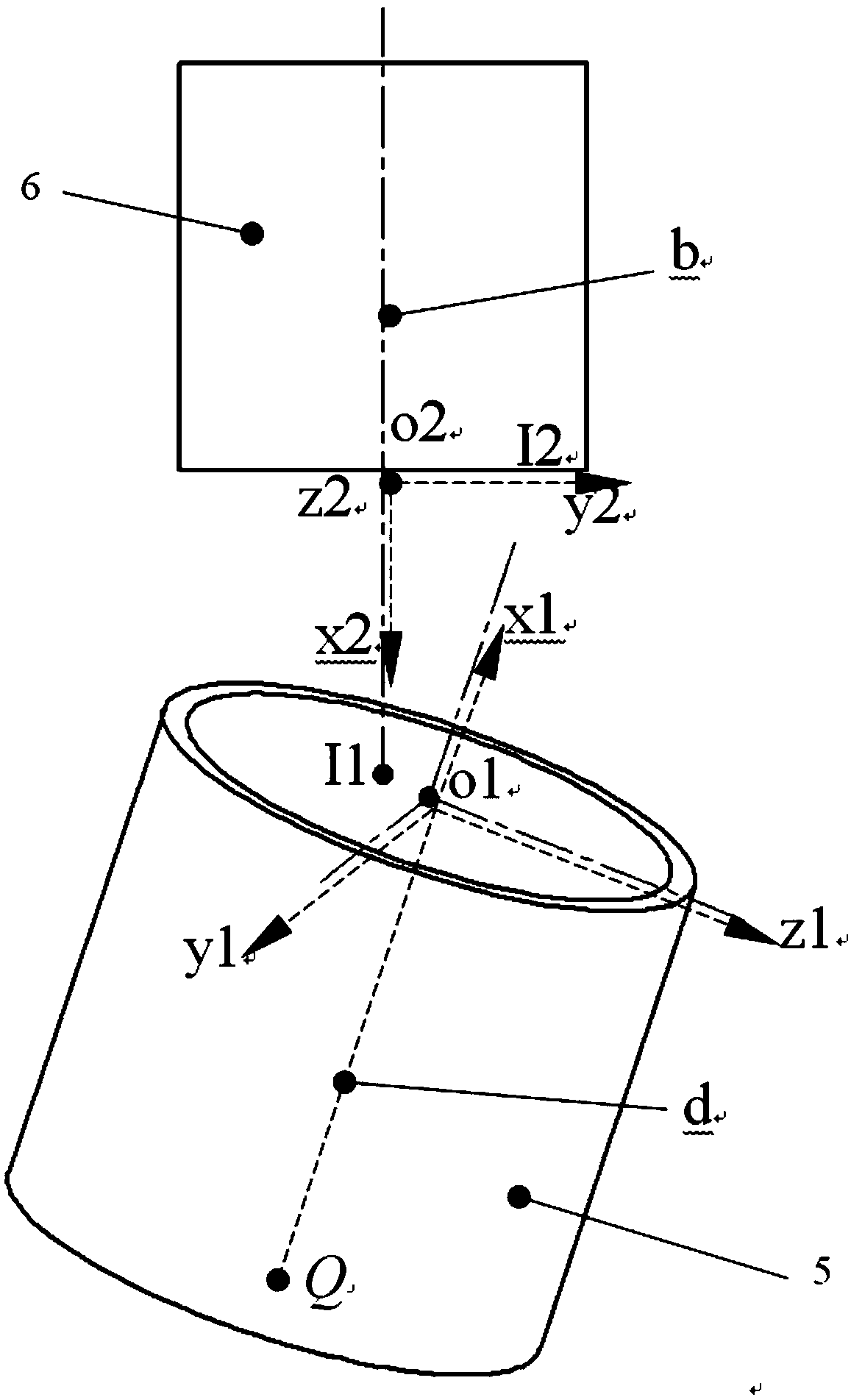

[0032] The present invention adopts the laser tool (LT, laser tooling) method, uses a highly collimated laser beam to "replicate" the inner wall axis of the cylinder, and measures the positions of intersections I1 and I2 with a PSD device that is automatically sensitive to the spot position (PSD: PositionSensitive Detector, Position Sensitive Detector). The device is composed of: hydraulic tensioning reference fixture 1, laser collimation light tube 2, centering disc 3, and centering ball 4, such as figure 2 shown.

[0033] The portable high-precision coaxiality measurement device proposed by the invention has a measurement capability better than Φ0.1mm.

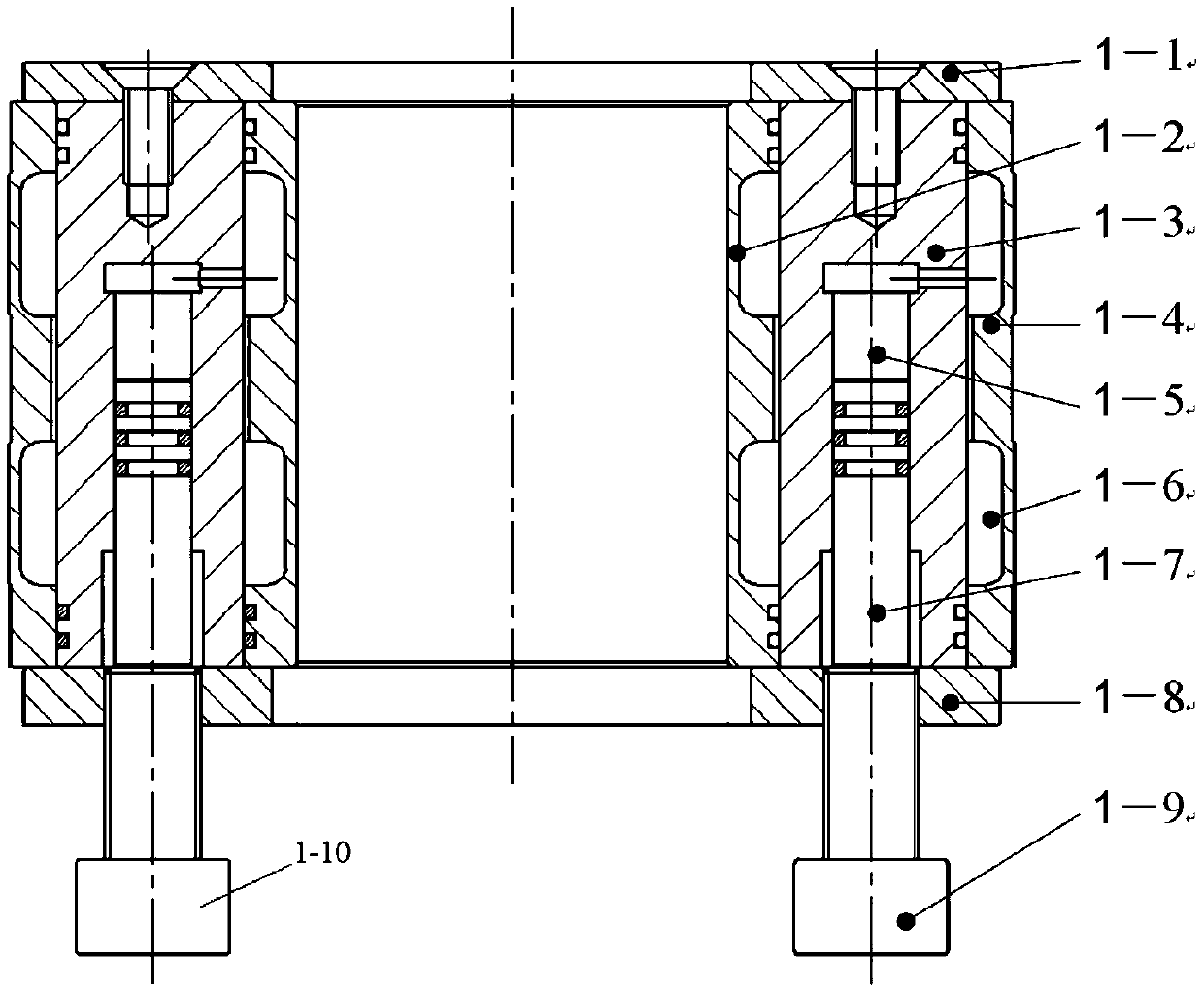

[0034] 2) Hydraulic expansion reference fixture 1

[0035] The axis of the product cylinder is one of the reference elements for high-precision replication of the measuring device. The present invention uses a highly collimated laser beam to "replicate" the axis of the product barrel.

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com