Visual inspection system and method for automatically detecting white glass surface defects

A detection system and automatic detection technology, applied in measuring devices, material analysis by optical means, instruments, etc., can solve problems such as increased cost, inability to obtain high-quality white glass surface defect images, no imaging, etc., and achieve high speed. high effect required

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] Embodiment 1, a visual detection system for automatic detection of surface defects of white glass, including four sub-devices such as a light source device, a microscopic vision device, a precision transmission device, and a control host computer. Among them, the light source system includes at least a light source, and may also include a light source controller and a light source attitude calibration device; the microscopic vision system includes at least a camera, a lens, and may also include a visual attitude adjustment device; the precision transmission device includes at least a roller transmission structure, a motor drive Structure; the control host computer can adopt traditional computer, industrial computer, and programmable controller.

[0032] From top to bottom, the camera is connected to the lens and is located directly above the light source. There is a light source box outside the light source. There is a light source gap on the box to allow the camera to c...

Embodiment 2

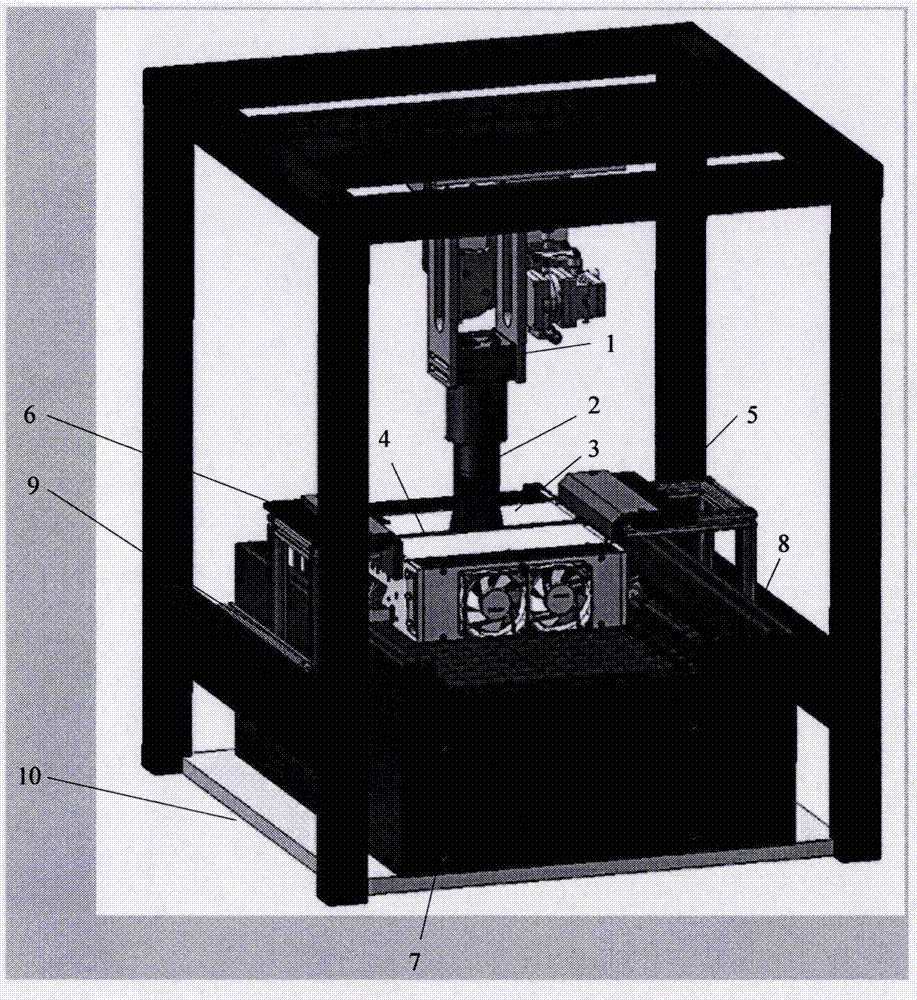

[0033] Example 2, such as figure 1 As shown, the line camera 1 is used to connect the lens from top to bottom, and it is located directly above the multi-angle light source 3. There is a light source box outside the multi-angle light source 3, and there is a light source slit 4 on the box body to allow the line camera 1 to pass through. The lens collects the image under the light source box body. The bottom of the light source box body is equipped with a roller conveying structure. The gap 4 of the light source is directly facing the gap between the rollers. When the roller 7 is transported to the light source gap 4, it is triggered by the photoelectric sensor 6 to start collecting images. When the white glass sheet passes directly under the light source gap 4, the camera collects images frame by frame. When the entire white glass sheet passes through, all image collection is completed. .

Embodiment 3

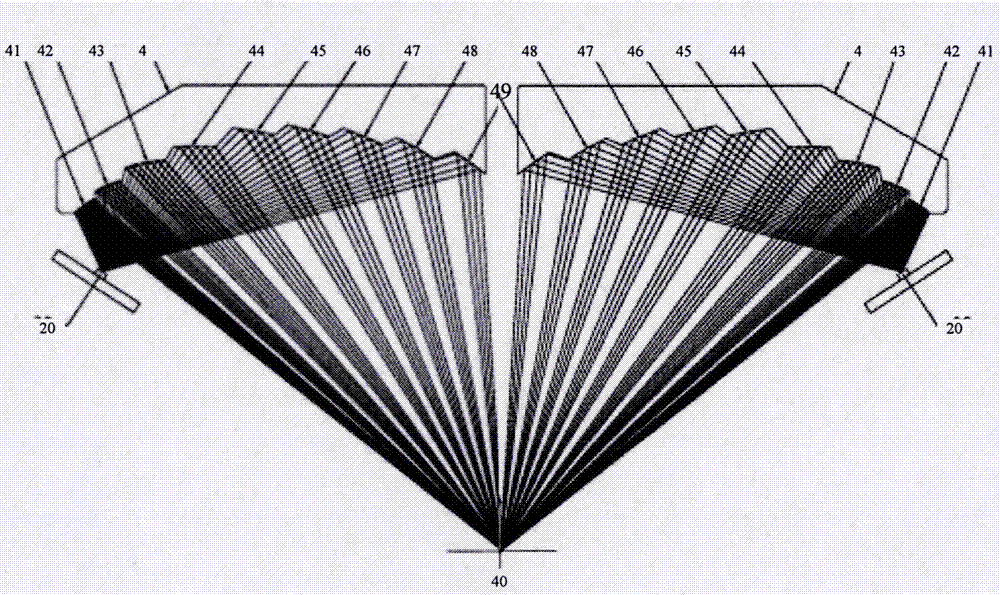

[0034] Example 3, such as figure 2The cross-sectional view of the embodiment structure of the multi-angle light source shown, a multi-angle line light source used in a visual inspection system for automatically detecting surface defects of white glass, including a group of LED chips 20 and a group of one or more different curvature radii. The mirror is composed of off-axis mirror units 41-49, wherein a group of LED chips 20 are arranged in the z-axis perpendicular to the paper surface, and the mirror units 41-49 are only 9 off-axis mirrors with different curvature radii. An example of a single unit (one or more off-axis reflectors with different radii of curvature can also be used in practice), one or more off-axis reflectors with different radii of curvature can separate the light emitted by each LED chip 20 Focusing on the focal point 40, the light emitted by a group of LED chips 20 at the same distance from the reflector is focused to each focus to form a line light along ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com