Fluid sample supply module

A technology for supplying modules and fluids, which is applied in the direction of analyzing materials and instruments, and can solve problems such as low efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The technical solutions of the present invention will be further described below in conjunction with the accompanying drawings and through specific implementation methods.

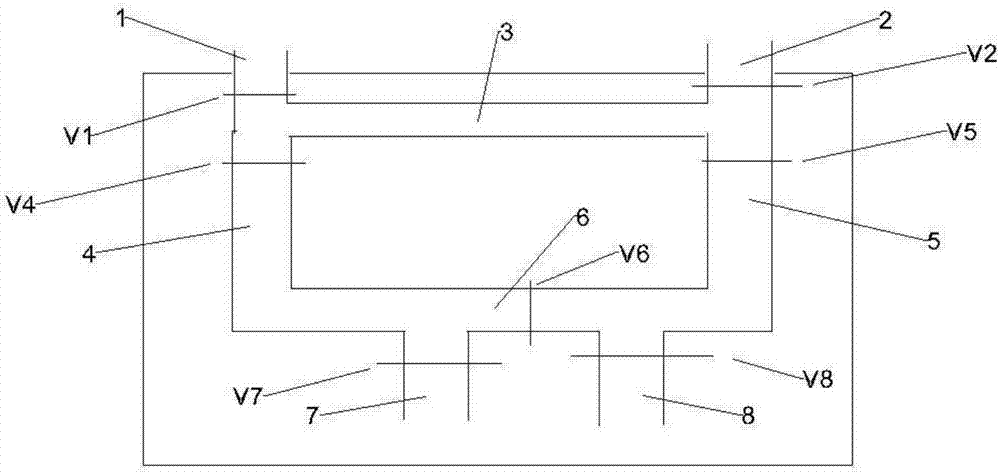

[0020] figure 1 It is a schematic structural diagram of the fluid sample supply module of the present invention, 1-sample suction tube, 2-sample feeding tube, 3-first multiplexing pipeline, 4-second multiplexing pipeline, 5-third multiplexing pipeline , 6-the fourth multiplexing pipeline, 7-cleaning liquid connecting pipeline, 8-air flow connecting pipeline, V1-V8 valve.

[0021] The first end of the suction pipe 1 is connected to the sample cell, the second end of the suction pipe 1, the first end of the first multiplexing pipeline 3 and the first end of the second multiplexing pipeline 4 are connected by a three-way connection. Valves V1 and V4 are respectively arranged on the sampling pipe 1 and the second multiplexing pipeline. Preferably, the valves V1 and V4 are respectively set on the second...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com