Sensor-actuator based on direct and inverse piezoelectric effects

A technology of inverse piezoelectric effect and piezoelectric actuator, which is applied in the field of measurement and control and sensing, can solve the problem of poor force direction accuracy, and achieve the effect of stable performance, reliability and high stability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

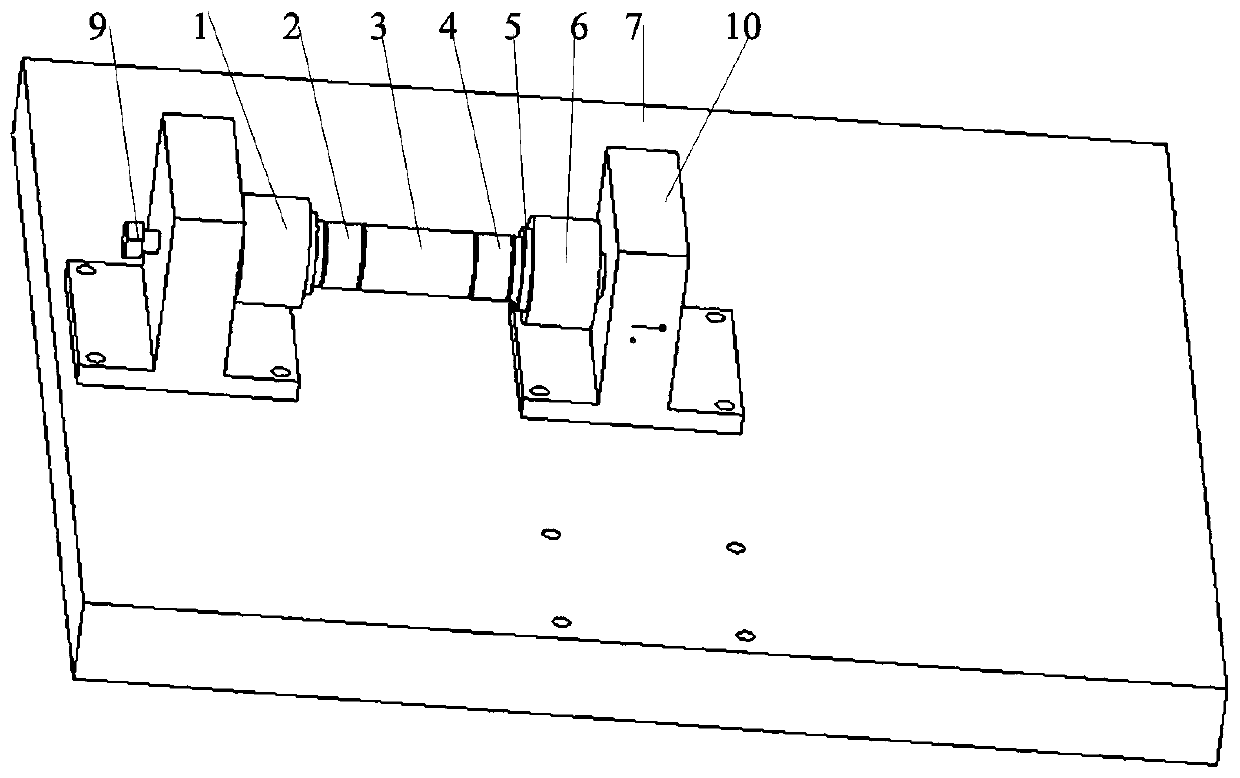

[0031] The specific implementation manners of the present invention will be further described below in conjunction with the accompanying drawings and technical solutions.

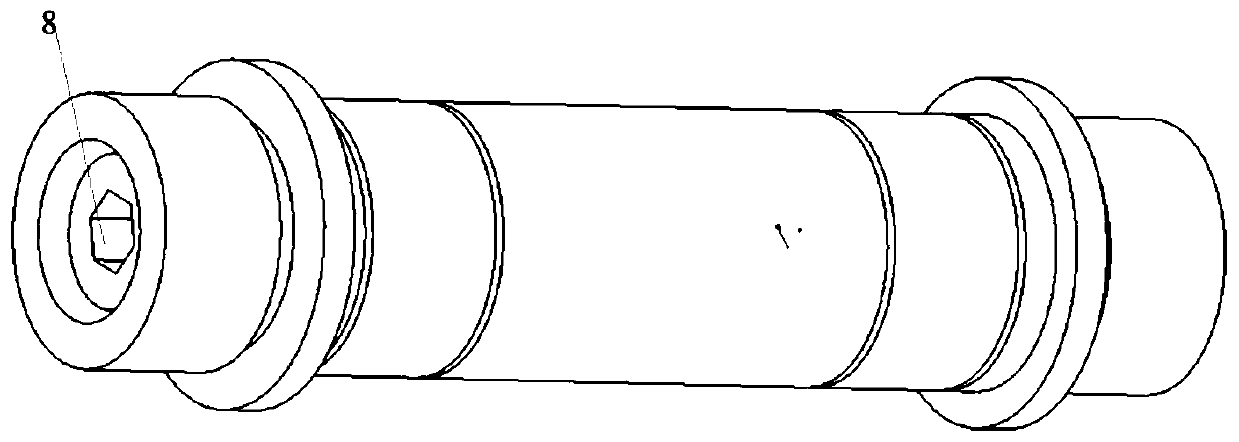

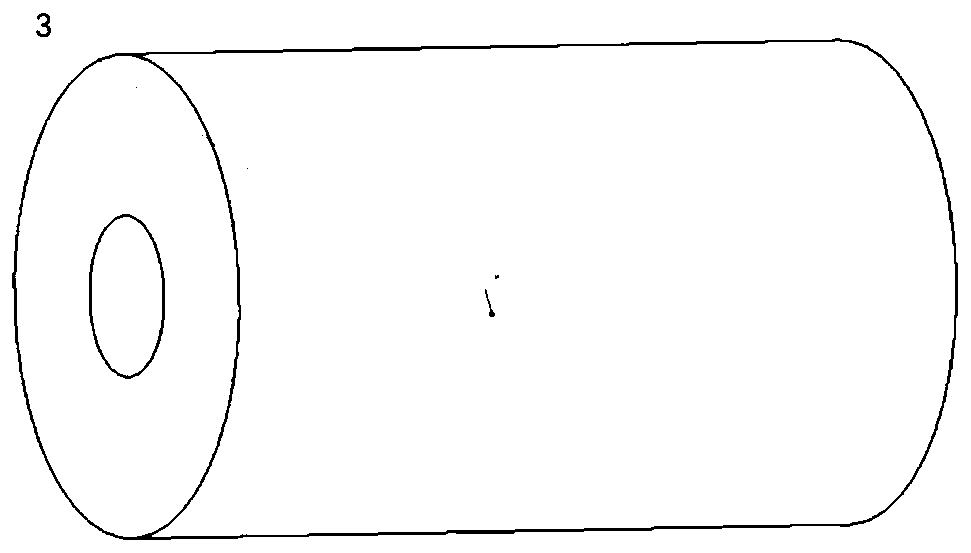

[0032] Sensing actuator based on positive and reverse piezoelectric effects, including actuator back cover 1, piezoelectric actuator 2, intermediate shaft 3, piezoelectric sensor 4, inner sleeve 5, sensor back cover 6, loading base plate 7, connecting bolts 8. Screw plug 9 and loading base 10;

[0033] The actuator rear cover 1 is an integral two-stage stepped shaft structure, the shaft on the side with the smaller diameter is a solid optical shaft, and its head is a hemispherical structure, which is connected to the optical hole on the loading base 10 The shaft hole fits to achieve the purpose of guiding; the shaft on the larger diameter side is a hollow shaft, and there is a concentric threaded hole inside. This threaded hole is threaded with the threaded shaft of the inner sleeve 5, and the actuator back...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com